wood pellet production line

Wood pellet production line for processing logs, branches, wood chips, brak, sawdust, forestry residues or other biomass raw materials into wood pellets. If you want to building a wood pellet production line, please contact us.

RICHI MACHINERY

RICHI wood pellet production line for sale

Wood pellet production line is customized according to customer needs, the wood pellet equipment used in the wood pellet production line is corresponding to its production process. The main wood pellet equipment includes drum wood chipper, wood hammer mill, conveying equipment, rotary drum drying machine, wood pellet machine, counterflow cooler, finished product packaging scale, thermoplastic sealing machine and so on.

- Main sources of raw materials: forestry leftovers such as sawdust, wood chips, branches, bark, etc., in the process of forest harvesting and garden pruning; wood blocks, shavings and other scraps produced in the process of wood processing and production; wood waste such as old furniture and old wood planks.

- Wood pellet size: generally 6-12mm in diameter and 4-5 times its diameter in length.

- Capacity: 0.5-40t/h

As an efficient and environmentally friendly biomass pellet fuel, wood pellets are in increasing demand and can replace traditional fossil fuels, such as coal, for industrial boilers, residential heating and other fields. So, wood pellet manufacturing plant came into being and has a broad prospect. Building a reasonable wood pellet production line for wood pellet plant is what RICHI Machinery has been doing. You can send us an inquiry for more information.

Process flow of wood pellet production line

For different raw materials and different production lines, the processes are not the same, the ultimate goals both are to produce combustible wood pellets.

1.Preparation

The pretreatment of raw materials mainly refers to the peeling and cutting of logs. In addition, the raw materials need to be cleaned to remove impurities.

2.Chipping

The prepared logs are cut into 3-5 cm slices to facilitate the processing of the crushing section. Standard wood pellet production line solutions will have the process.

3.Crushing

Crushing 3-5cm of small wood blocks and small production chips into 3-5mm of sawdust. This process is required for most raw materials.

4.Drying

The general moisture content of wood is large, and the crushed sawdust needs to be dried first, and the moisture can be reduced to about 15% before they can be pelleted.

5.Homogenizing

The effect of homogenization is to make the water content of sawdust uniform, which is easy to pelletize.

6.Pelletizing

Pelletizing is the main process of the wood pellet production line. The crushed and dried wood sawdust is added to the wood pellet press machine for pressing and forming.

7.Cooling

Temperature of the wood pellets coming out of wood pellet machine is about 90℃. And it needs to be cooled to make the wood pellets stable and not easy to break.

8.Packing

The cooled wood pellets are packaged, and some pellet manufacturers use thermoplastic sealing in order to prevent the pellets from getting wet.

Wood Pellet equipment on the line

Drum wood chipper

The drum wood chipper has a wide range of application advantages in the field of wood processing, and can efficiently crush logs and other logs into the required size. Providing uniform raw material for subsequent grinding process. Drum wood chipper also has the characteristics of simple operation and easy maintenance, which can reduce the labor intensity of workers and improve work efficiency. The log that can be processed by the drum wood chipper is measured according to its inlet size.

Wood hammer mill

The wood hammer mill is similar to the one used in the feed pellet production line. However, the wood materials are harder and require stronger strength, the screen will be extra thick, and the motor will be smaller. Wood hammer mill has the advantages of simple structure, compact layout and easy operation and maintenance. It has the advantages of low energy consumption, high yield and good quality of sawdust.

Drying machine

The rotary drum drying machine of RICHI Machinery adopts the method of horizontal placement and wind transport. The advantage is that the wind transport has a preliminary screening function, and the sawdust can be transported only when the moisture is reduced to about 15%, that is, when the wood pellet machine is suitable for granulation. Compared with the inclined dryer, it can better control the moisture content of sawdust. The capacity of the rotary drum drying machine is calculated according to the water content of the raw material from 50% to 15%.

Buffer bin or material bin

The function of the buffer bin is similar to that of the material bin, which is used to store the materials produced after the end of one section and prepare for the next section. With the buffer bin, it is possible to ensure the continuity of the wood pellet production line. Behind the rotary drum drying machine on the wood pellet production line, there is generally a storage bin, which also has a homogenizing mixing function. Let the sawdust to enter the wood pellet mill, water mix evenly. This allows the wood pellet mill to produce higher quality wood pellets.

Wood pellet machine

RICHI MZLH series wood pellet machine is the core equipment of wood pellet production line. The capacity of a wood pellet production plant is closely related to the capacity of wood pellet making machine. So, it is very important to choose a good wood pellet machine.

RICHI MACHINERY provide our customers with high output, high quality, low energy consumption of wood pellet machines.

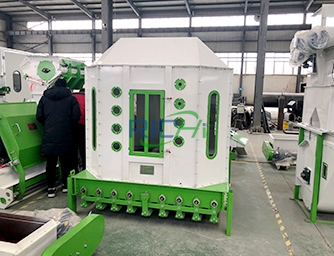

Counterflow cooler

Counterflow cooler is used for cooling finished wood pellets. Using indoor air, the wood pellets are cooled to the room temperature.

Packaging machine

In the packaging system after the wood pellets are formed, the finished product packaging scale will be equipped to automatically weigh and pack.

The plastic sealing machine is required by some customers in order to moisture-proof wood pellets.

Conveying equipment

Conveying equipment generally has bucket elevator, U-screw conveyor, wind transport system, belt conveyor, roll conveyor. Bucket elevator is used for lifting and conveying materials in the vertical direction. U-screw conveyor is used for short distance, horizontal or inclined conveying of powdery materials. Air transport system is used for vertical transport of light materials. Belt conveyor is used for conveying materials with small angle and large output. The customized conveyor is used for conveying short distance and large angle or finished pellets, and is mostly used for pellet production lines with limited height.

RICHI MZLH Wood Pellet Machine

RICHI SZLH wood pellet machine is designed according to the characteristics of sawdust. Sawdust is relatively light, poor mobility, easy to knot arch. So, the wood pellet machine has two places to take it different from the configuration of ordinary feed pellet machine. One is the anti-knot arch device on the feeder, and the other is in the door cover of the wood pellet machine is equipped with a forced feeder to ensure the smooth transmission of materials. The molding rate of our wood pellet machine can reach more than 98%.

RICHI MZLH wood pellet machine has mutiple models, you can choose according to the capacity or your own needs.

| Model | MZLH320 | MZLH350 | MZLH420 | MZLH520 | MZLH768 | MZLH858 |

| Capacity(t/h) | 0.3-0.5 | 0.5-0.7 | 0.8-1.5 | 2-2.5 | 2.5-4 | 4-5 |

| Power(kw) | 22 | 37 | 90 | 132 | 250 | 280 |

| Pellet size(mm) | 6-12 | 6-12 | 6-12 | 6-12 | 6-12 | 6-12 |

Why build a wood pellet production line?

As a kind of renewable biomass fuel, wood pellet has large heat, high combustion purity, no sulfur and phosphorus. And has the role of protecting the environment and saving energy. The ash after the combustion of biomass pellets is a high-quality organic potassium fertilizer with high taste, which can be recycled. Most of the raw materials of wood pellets are waste, and the price is relatively low.

There are many countries and regions with lush vegetation and rich forestry resources. However, deforestation is excessive, and a lot of wood resources are wasted. If there is a wood pellet production line, these resources can be reused. Some of our clients come from that.

Advantages of the RICHI wood pellet production line

Customizable. RICHI Machinery has a variety of pellet production line design solutions, customers can choose their own, or let our industrial machinery designers customized for you. Of course, the design is free.

Ensure production. The actual capacity of the installed wood pellet production line is the same as the marked capacity of the machine you purchased. This is closely related to the quality of our machines and the mode of transport on the production line. For example, the slide design of the finished product bin enables wood pellets to enter the packaging system more completely.

Higher quality. Since we have also done a lot about chicken feed and aquatic feed pellet production equipment over the years, the edible machinery for animals is very strict. So, in the biomass pellet production line, we also followed the common advantages of the feed pellet production line, and made targeted changes for the characteristics of biomass. For example, wood pellet machines require higher grade motors because wood pellets need to be pressed more slowly and with greater force than feed pellets.

Design properly. We have construction experience for more than 1000 pellet production lines. In the automatic line, composite line (can produce different kinds of pellets), semi-automatic line, artificial line have successful practical cases. Our wood pellet production lines are designed to be more efficient, saving space and cost. In addition to the production of wood pellets, wood pellet production line can also be used to produce biomass pellets, straw pellets, peanut shell pellets and so on.

RICHI 2T/h wood pellet production line in Romania

The 2 tons per hour production line was sold on August 2, 2022, with the complete wood pellet production line price of about 230,000 US dollars, the installation cycle is 60 days, and the raw material is 100% beech sawdust.

The Romanian company chose its wood pellet production line because it wanted to provide an effective solution to uncontrolled deforestation. At the same time, they think wood pellets have better prospects and wider uses. Wood pellets are more efficient and environmentally friendly to burn.

We designed a feasible plan according to the customer’s plant area, the wood pellet equipment problems at that time, the future direction of development, the customer’s cost and benefit, the market and quotation , and the raw materials.

Because the customer’s raw material is 100% beech sawdust, chipping and crushing sections are eliminated.A pulse dust collector is installed on the buffer bin to protect the working environment. The horizontal rotary drum drying machine is carried by air to obtain sawdust suitable for pelletizing. The dried material is connected with three-way isolating valve, which can allow workers to feed separately and also play an emergency role. The blower and cyclone are installed next to the wood pellet machine, which can pull out the water vapor and a small amount of sawdust in the wood pellet mill to protect the working environment. The main conveying equipment in the wood pellet production line is U-screw conveyor and bucket elevator. The 2 t/h wood pellet production line is economical, efficient and environmentally friendly for the Romanian customer. The success of this wood pellet production line makes the customer very happy and very satisfied with the service of RICHI Machinery.