Wood chip pellet machine

Wood chip pellet machine, also known as wood chip pellet marker or biomass wood pellet machine, is a biomass energy equipment that converts wood chips, straw, rice husks, and other agricultural and forestry wastes into high-density biomass pellet fuels.

RICHI MACHINERY

Brief of RICHI MZLH Series Wood chip pellet machine

RICHI MZLH Series Wood chip pellet machine is a quality wood pellet equipment for sale. RICHI Machinery’s factory has a higher intelligence and automation technology, so the production efficiency and product quality of our wood chip pellet marker are also in the industry-leading position. With the rational development and utilization of forest resources, as well as the continuous progress of biomass energy equipment technology, RICHI MZLH Series Wood pellet machines with their unique advantages are leading the new trend of energy transformation and becoming a leader in this field. Besides, as the core equipment of the wood pellet production line, the function of the wood chip pellet machine is turning sawdust into wood pellets, or turning biomass into biofuels.

- Capacity: 0.3-5T/H

- Applicable raw materials: wood chips, straw, husk, fruit shells, and other log materials and organic waste.

- Pellet diameter: 6-12mm

- Type: ring die pellet machine

- Customizable ring die: Yes

- Main motor series: 6/8P

Customers can customize the wood chip pellet machines according to their own needs. As well as, RICHI Machinery can provide customers with turnkey service to meet the needs of wood pellet factories.

Details of RICHI MZLH Wood Chip Pellet machine

Next, let’s first understand the basic components and working principle of RICHI MZLH wood chip pellet machine.

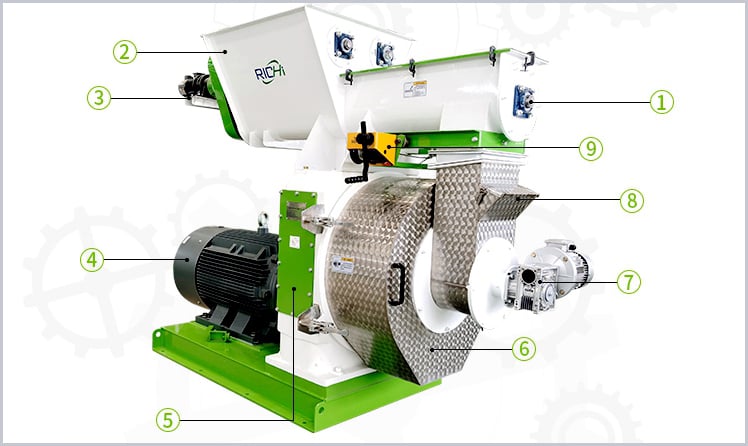

Components of wood chip pellet machine

- SKF bearing

- Anti-cake device

- Frequency feeder

- Siemens motor

- Gear box

- Pelletizing chamber

- Forced feeder

- Material inspection port

- Ring die hoist

Working Principle

Its working principle mainly relies on mechanical extrusion and high-temperature forming technology. The crushed, dried and evenly mixed materials enter the wood chip pellet maker from the feeding device and chute, and uniformly enter the pelletizing chamber under the combined action of the forced feeder, the centrifugal force generated by the rotation of the ring die, and the feeding scraper.

Then, through the strong extrusion of the ring die and the press roller, the materials are discharged from the die hole of the ring die and cut into the desired length by the cutter. It should be noted here that the inner diameter of the ring die hole is the diameter of the finished wood pellets.

Advantages of RICHI MZLH Wood chip pellet machine

Our wood pellet machines for sale have unique materials, fittings, structure, design, and technology advantages.

More durable and Convenient

Ring die, granulation chamber door and other important parts are made of stainless steel, more durable. In addition, the ring die adopts quick- release type hoop type, which is more convenient for maintenance and replacement.

High-quality Accessories

Accessories are selected high quality and well-known brands, such as Siemens motor, SKF bearings, high-quality imported oil seals, etc. Therefore, the wood chip pellet machine can operate efficiently, stably, and with low noise.

Multiple innovations

RICHI has multiple innovations in the design of ring molds. It not only improves the quality of the ring die and reduces the frequency of the ring die replacement for customers, but also increases the hourly and total capacity of wood chip pellet maker.

International advanced coupling

The international advanced level of compensation type snake spring coupling, with novel structure, compact, safe, low fault and other performance.

Longer service life

RICHI MZLH Wood pellet machines for sale are equipped with overload protection devices, improving the service life of the biomass wood pellet machine.

Better wood pellets

Through heat treatment and other processes, strengthen the working intensity of the main working parts, so that final pellets have higher molding rate and smoothness.

Models And Parameters Of RICHI Wood Chip Pellet Machine

Richi Machinery has various models of wood pellet machines for sale to meet the needs of different customers.

MZLH320 Biomass Wood Pellet machine

- Capacity: 0.3-0.5T/H

- Main power: 22kw

- Main motor series: 6/8P

- Ring die diameter: 320mm

- Finshed pellet diameter: 6-12mm

MZLH350 Wood Chip Pellet machine

- Capacity: 0.5-0.7T/H

- Main power: 37kw

- Main motor series: 6/8P

- Ring die diameter: 350mm

- Finshed pellet diameter: 6-12mm

MZLH420 Wood Chip Pellet maker

- Capacity: 0.8-1.5T/H

- Main power: 90kw

- Main motor series: 6/8P

- Ring die diameter: 420mm

- Finshed pellet diameter: 6-12mm

MZLH520 Wood Pellet Machine Marker

- Capacity: 2-2.5T/H

- Main power: 132kw

- Main motor series: 6/8P

- Ring die diameter: 520mm

- Finshed pellet diameter: 6-12mm

MZLH768 Sawdust Pellet machine For Sale

- Capacity: 2.5-4T/H

- Main power: 250kw

- Main motor series: 6/8P

- Ring die diameter: 768mm

- Finshed pellet diameter: 6-12mm

MZLH858 Wood Pellet machine For Sale

- Capacity: 4-5T/H

- Main power: 280kw

- Main motor series: 6/8P

- Ring die diameter: 858mm

- Finshed pellet diameter: 6-12mm

RICHI MACHINERY

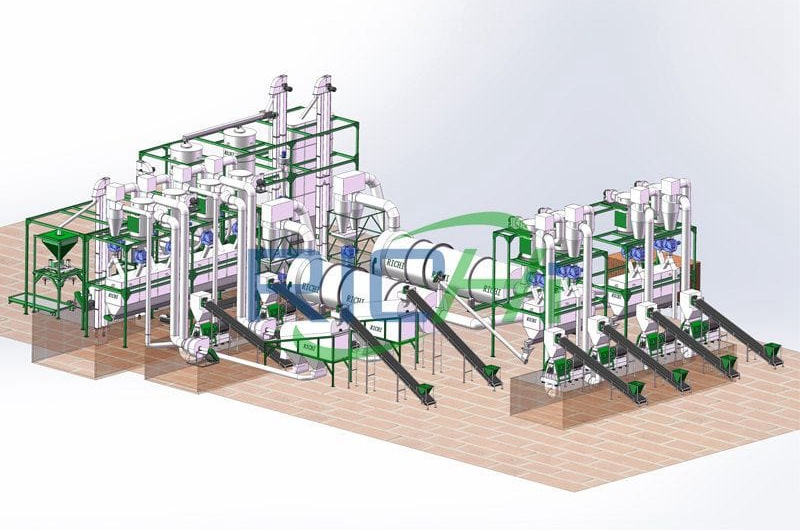

Wood chip pellet machine on wood pellet production lines

Wood pellet chip machine is the core equipment of the pelletizing section of wood pellet production lines or other biomass pellet production lines, which is mainly used to press the crushed materials into 6-12mm pellet fuels.

Main Processes of wood pellet production line

Wood pellet production line converts logs or other biomass raw materials into high-quality pellet fuel through a series of complex processes. Firstly, the raw materials are crushed by a grinding machine, which breaks them into fine wood chips. Secondly, these wood chips are dried in a wood drum dryer to remove excess water content and achieve the appropriate moisture content (about 15%). Thirdly, the dried wood chips are fed into the wood chip pellet maker for compression molding. Wood chip pellet maker adopts the principle of roller pressing, through the action of high temperature and high pressure, the wood chips are tightly compressed into regular pellet shape. Finally, you can get the finished wood pellets after cooling, screening, and packaging sections.

main functions of wood chip pellet machine

High-efficiency granulation. Wood chip pellet machine is the key biomass energy equipment to achieve wood pellet granulation on the wood pellet production line. It can compress loose wood chips into wood pellets with high density and strength, which significantly improves the combustion efficiency and energy density of wood chips.

Quality control. Through the precise control of the wood chip pellet machine, you can produce uniform specifications and stable quality of wood pellets. These wood pellet fuels not only have good combustion performance but also are easy to store and transport, meeting the needs of biomass fuels in different fields.

Why choose wood chip pellet maker?

Environmental protection and energy saving

Wood pellets as a biomass fuel, the carbon dioxide emissions generated during the combustion process are much lower than that of fossil fuels. Achieving the closure of the carbon cycle and helping to alleviate the greenhouse effect. At the same time, the high combustion efficiency of wood pellet fuels reduces energy consumption and pollution emissions.

Cost-effective

Compared to conventional fuels, wood pellet fuels are inexpensive, and are easy to store and transport. The raw materials come from a wide range of sources. For wood processing, agriculture and other industries, the application of wood chip pellet maker can also effectively reduce the cost of waste treatment and increase the income of enterprises.

Widely applications

Wood pellets are not only suitable for home heating, industrial boilers, power stations and other scenarios, but also ideal raw materials for advanced energy conversion technologies such as biomass gasification and liquefaction, showing broad market prospects.

Policy support

With the global emphasis on renewable energy, governments have introduced relevant policies to encourage the development of biomass energy. As an important part of it, wood chip pellet maker has enjoyed preferential policies such as tax breaks and subsidies, which further promoted its industrialization process.

About

Why choose Biomass wood pellet machine from RICHI machinery?

As the most professional biomass wood pellet machines manufacturer in China, Henan Richi Machinery Co., LTD. has the largest biomass energy equipment manufacturing plant in Henan Province. We have many years of experience in the design and production of biomass energy equipment, and our wood chip pellet machines have been exported to many countries.

In addition, as a one-stop solution provider, we have established many pellet production plants for global customers, of which wood chip pellet machines as one type of main equipment are praised by customers.

500+

Device Models

29+

Years Experience

127+

Countries and Regions

2000+

Customers

Related cases of wood chip pellet maker

Our wood pellet machines are sold all over the world and are used in wood pellet production projects established for our customers.

wood pellet production line in Austria

- Date: December 2018

- Capacity: 5T/H

- Raw materials: Wood chips

- Main equipment: MZLH520 wood chip pellet machine*2, SFSP66*80 wood crusher, ф2400*100000 *3 rotary drum dryer, SKLN17*17 pellet cooler, DSC-50 packing machine, etc.

Biomass Wood Pellet Plant in Anhui Province, China

- Date: October 2020

- Capacity: 28T/H

- Raw materials: Rice husk, Miscellaneous wood

- Main equipment: MZLH520 biomass wood pellet machine*12, wood chipper machine, wood hammer mill, SKLN pellet cooler, automatic packing system, etc.

Wood pellet production line in Canada

- Date: August 1, 2018

- Capacity: 2-3T/H

- Raw materials: 50% moisture wood chips, 50% moisture sawdust

- Main equipment: MZLH wood chip pellet maker, wood crusher, rotary drying machine, SKLN pellet cooler, automatic packing machine, etc.

Frequently Ask Question

Frequently Ask Question

How to start wood pellet business?

- You can first identify your own raw materials, such as logs, wood chips, sawdust, straw, grass, or other biomass raw materials.

- Understand the market and demand to determine the size and capacity of wood pellets you want to produce.

- Choosing wood pellet production plant solutions and wood pellet equipment. Here, a reliable manufacturer and exporter is very necessary.

- Follow the local policy for setting up a wood pellet plant step by step.

Importantly, RICHI Machinery can provide you with a one-stop solution for 0.3-40T/H wood pellet production lines, and has a complete set of wood pellet equipment for sale.

If you want to start a wood pellet business, you can contact us. We have experience around the world that you can learn from.

What equipment is needed to make wood pellets?

This depends on your raw materials. General logs, wood blocks, straw, and other biomass raw materials need crushing machine, drying machine, wood chip pellet maker, cooler, packing machine and so on. You can choose according to your specific needs. However, the wood chip pellet machine is the most common and required biomass energy equipment, and its quality is also crucial for the production of wood pellets.

How much does a wood chip pellet machine cost?

The price of a wood chip pellet machine is about 15,000-50,000 US dollars. We have 0.3-5T/H wood pellet equipment for sale. In addition, we can also provide customers with personalized wood chip pellet machines.

Any Question?

You can ask anything you want to know about Feedback