Shrimp feed pellet machine

Shrimp feed pellet machine is the main equipment for the production of various shrimp feed, prawn feed and sinking fish feed pellets, with high output, low energy consumption, cheap price and other advantages, has been favored by many shrimp feed pellet production plants and manufacturers. This page introduces RICHI shrimp feed pellet machine which is easy to use and cost-effective.

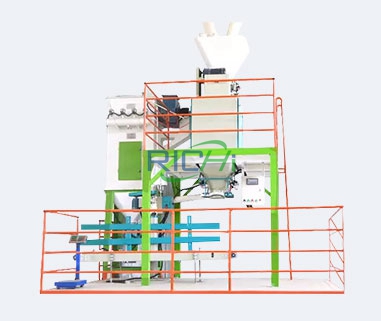

RICHI 0.2-15T/H SZLH Shrimp Feed Pellet Machine

RICHI shrimp feed pellet machine is a ring die feed pellet maker developed, designed and manufactured by HENAN RICHI Machinery, it produces shrimp feed pellets with high nutritional value and good water resistance.

The shrimp feed making machine is suitable for processing fish meal, soybean meal, peanut meal, rapeseed cake, shrimp shell meal, wheat meal, crab meal, granulesten, yeast powder, calcium dihydrogen phosphate MCP, salt and other raw materials. These raw materials are the main components of the shrimp feed pellet formula, provide essential nutrients for shrimp growth.

- Models: SZLH series shrimp feed pellet machine

- Range of price: $7,000-$100,000

- Capacity: 0.2-15T/H

- Motor series: 4P, 6P, 8P

- Pellet size: 1-3mm

- Feature: 3-layers conditioner or DDC, customizable

- Types of shrimp: farmed shrimp, prawn, Penaeus vannamei, Australian lobster, Metapenaeus ensis, freshwater shrimp, Asian tiger shrimp, black tiger shrimp, bamboo shrimp, giant river prawn, fairy shrimp and so on.

Shrimps first break feed pellets into small pieces and then eat them in their mouths, unlike fish, which can swallow whole pellets in one gulp, and shrimp have a weaker digestive system. Therefore, shrimp feed mill needs a machine for the production of feed pellets that are stable in water and easier to digest. If you are looking for or want to buy a shrimp feed pellet machine, please contact us.

Structure features and details of RICHI shrimp feed making machine

RICHI shrimp feed machine’s structure and its details are designed according to the feeding habits of shrimp and shrimp feed characteristics, the aim is produce high quality shrimp feed pellets. We introduce the shrimp feed pellet machine from top to bottom.

Variable frequency feeder

Frequency conversion motor, stainless steel conditioner and gear reducer together form the variable frequency feeder of the machine. In actual operation, the feeder is often connected with an anti-arching barrel. Thus, the shrimp feed can be uniformly fed into the conditioner.

Like the RICHI animal feed pellet machine, all feeder, conditioner, feeder inlet, ring die and other parts in contact with the feed are made of food grade 304 stainless steel, which can be seen by the embossing process.

Three-layer stainless steel conditioner or DDC

Compared with one layer and two layers, the three-layer conditioner doubles the modulation time of the shrimp feed, so the gelatinization effect of the feed is better, which will be conducive to the molding of the shrimp feed. At the same time, the degree of maturation is also higher, which is conducive to the digestion and absorption of shrimp. Sterilization is more thorough, reducing the incidence of disease.

The machine can also use a double-shaft differential conditioner (DDC) to improve the modulation time.

The conditioner is equipped with an observation ports, which make it more convenient to observe and adjust the modulation state at any time.

Tips: Shrimp feed preparation temperature is above 90℃-110℃, and the preparation time is above 150-300s.

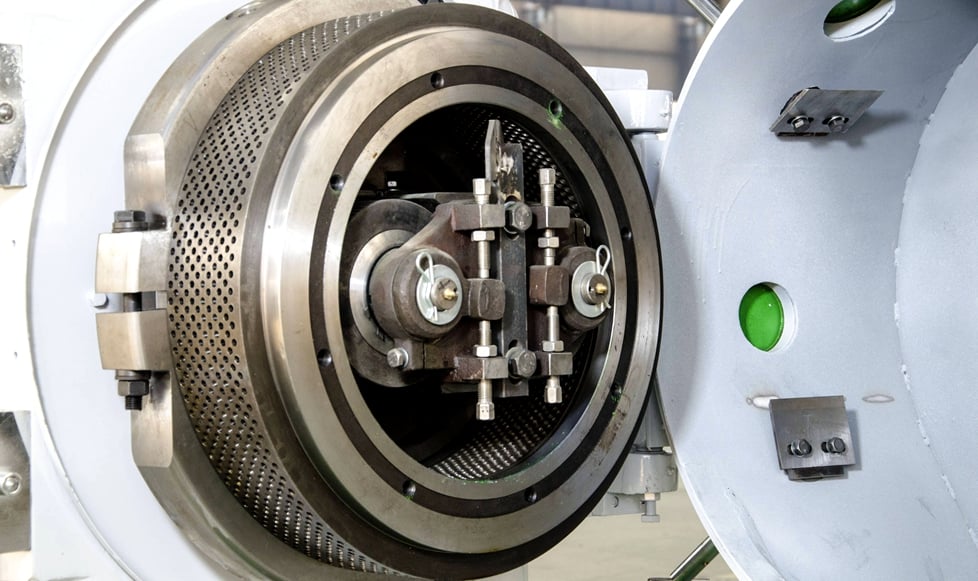

Granulation chamber

The main parts of the pelleting chamber include the special shrimp feeding switch-plate, press rollers, ring die and cutters. The modulated materials enter the granulation chamber through the chute, and the material plate evenly disperses them between the ring die and the press rollers, and then extrude the ring die hole, are cut by cutters.

Tips: The diameter of shrimp feed pellet is generally 1-3mm, and the length is 1.5-2 times the diameter. The compression ratio of shrimp feed ring die is 1:20-1:25.

The thickness of the cutter slice is 2-3mm, which is thinner than the cutter of the traditional livestock and poultry feed granulator, and is more close to the ring die, which is conducive to the production of small size shrimp feed pellets and reduce the powder content.

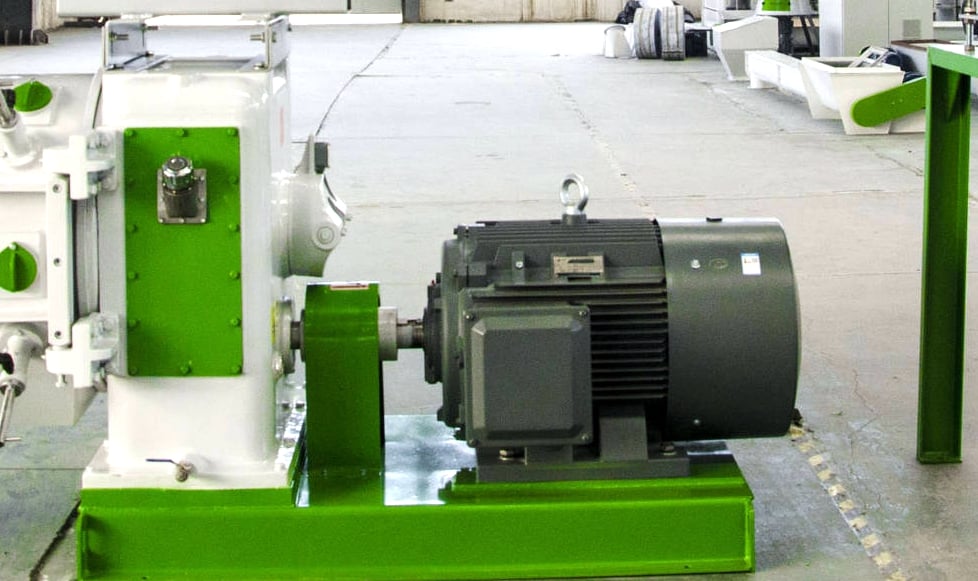

Siemens Motor

Because the shrimp feed compression ratio is higher, it is more difficult to granulate, so a higher series of motor is required. The higher the motor series, the slower the speed, the greater the torque and the greater the force. The principle is similar to that of a wood pellet machine.

The main motor of the equipment uses Siemens motors, but the series is 4P, 6P or 8P. The 4P motor is suitable for the production of 2-3mm shrimp feed pellets, the 6P motor is suitable for 1.5-2mm shrimp feed pellets, and the 8P motor is suitable for 1.0-1.2mm shrimp feed pellets.

Technical parameters of RICHI shrimp feed pellet machine

Through 30 years of experience and a lot of data analysis, we selected the shrimp feed pellet models commonly used by customers. Of course, this is only a possibility, you can also contact us to customize.

shrimp feed making machine

- Model: MZLH250

- Capacity: 0.2-0.4T/H

- Main motor power: 22kw

- Feeder power: 0.75kw

- Conditioner power: 1.5kw

- Ring die diameter: 250mm

- Finished shrimp feed pellet diameter: 1-3mm

Shrimp feed pellet machine

- Model: MZLH 320

- Capacity: 0.3-1T/H

- Main motor power: 22KW

- Feeder power: 1.5KW

- Conditioner power: 2.2KW

- Ring die diameter: 320mm

- Finished shrimp feed pellet diameter: 1-3mm

prawn feed making machine

- Model: MZLH 350

- Capacity: 0.5-2T/H

- Main motor power: 37kw

- Feeder power: 1.5kw

- Conditioner power: 3kw

- Ring die diameter: 350mm

- Finished shrimp feed pellet diameter: 1-3mm

prawn feed manufacturing machine

- Model: MZLH 420

- Capacity: 1.2-4kw

- Main motor power: 90kw

- Feeder power: 1.5kw

- Conditioner power: 7.5kw

- Ring die diameter: 420mm

- Finished shrimp feed pellet diameter: 1-3mm

aquatic feed mill

- Model: MZLH508

- Capacity: 2.0-5T/H

- Main motor power: 132kw

- Feeder power: 2.2kw

- Conditioner power: 11kw

- Ring die diameter: 508mm

- Finished shrimp feed pellet diameter: 1-3mm

shrimp feed pellet mill

- Model: MZLH558

- Capacity: 3-8T/H

- Main motor power: 180/200kw

- Feeder power: 2.2kw

- Conditioner power: 11kw

- Ring die diameter: 558mm

- Finished shrimp feed pellet diameter: 1-3mm

shrimp feed mill

- Model: MZLH678

- Capacity: 4-10T/H

- Main motor power: 220/250kw

- Feeder power: 2.2kw

- Conditioner power: 11kw

- Ring die diameter: 678mm

- Finished shrimp feed pellet diameter: 1-3mm

shrimp feed machine

- Model: MZLH768

- Capacity: 4.5-12T/H

- Main motor power: 250/280kw

- Feeder power: 2.2kw

- Conditioner power: 11kw

- Ring die diameter: 768mm

- Finished shrimp feed pellet diameter: 1-3mm

sinking fish feed machine

- Model: MZLH858

- Capacity: 5.5-15T/H

- Main motor power: 315/355kw

- Feeder power: 2.2kw

- Conditioner power: 15kw

- Ring die diameter: 858mm

- Finished shrimp feed pellet diameter: 1-3mm

Note: Parameters are variable, send an inquiry for current details.

Prawn feed making machine market value

As a high-protein meat, shrimp is very common and best-selling, and the price of shrimp feed is higher, and the return on investment of shrimp feed machine is also high. Let’s take prawns for example.

Penaeus vannamei

Prawn is one of the most productive farmed species in the world, of which the Penaeus vannamei(White leg shrimp or White shrimp) is the most common and is more concentrated in the waters off Ecuador. The shrimp has delicious taste, high meat yield, wide salt, high temperature resistance and fast growth, so consumers and aquaculture producer like it very much.

Now, the Penaeus vannamei has been cultivated in high density, feed quality has become more and more important, the cost of feed in the production cost is relatively large. Therefore, prawn feed industry is also developing very well.

Prawn feed ingredients

In order to meet the nutritional requirements of the shrimp, the feed needs to contain 28%-32% crude protein, 3%-8% crude fat, ≤11% water content, ≤15% ash content and ≤5% crude fiber.

At the same time, the general raw material ratio is 30% fish meal, 25% peanut meal, 10% whole wheat flour, 6% shrimp bran, 6% yeast, 5% cottonseed meal, 2% maifan stone, 2% mixed oil and 14% premix. The premix contains vitamins, trace elements, choline, phospholipids and so on.

It can be seen that prawns are high quality and high protein meat with high nutritional value.

Prawn feed manufacturing machine

The prawn feed formula needs to be processed by the prawn feed manufacturing machine to form prawn feed pellets. The price of shrimp feed pellets is about three times that of chicken feed pellets, so the prawn feed manufacturing machine is also a high-yield investment equipment with a high market value.

Of course, the production of shrimp feed pellets also needs the support of other auxiliary equipment, then customers often choose to invest in a shrimp feed production line or shrimp feed pellet mill.

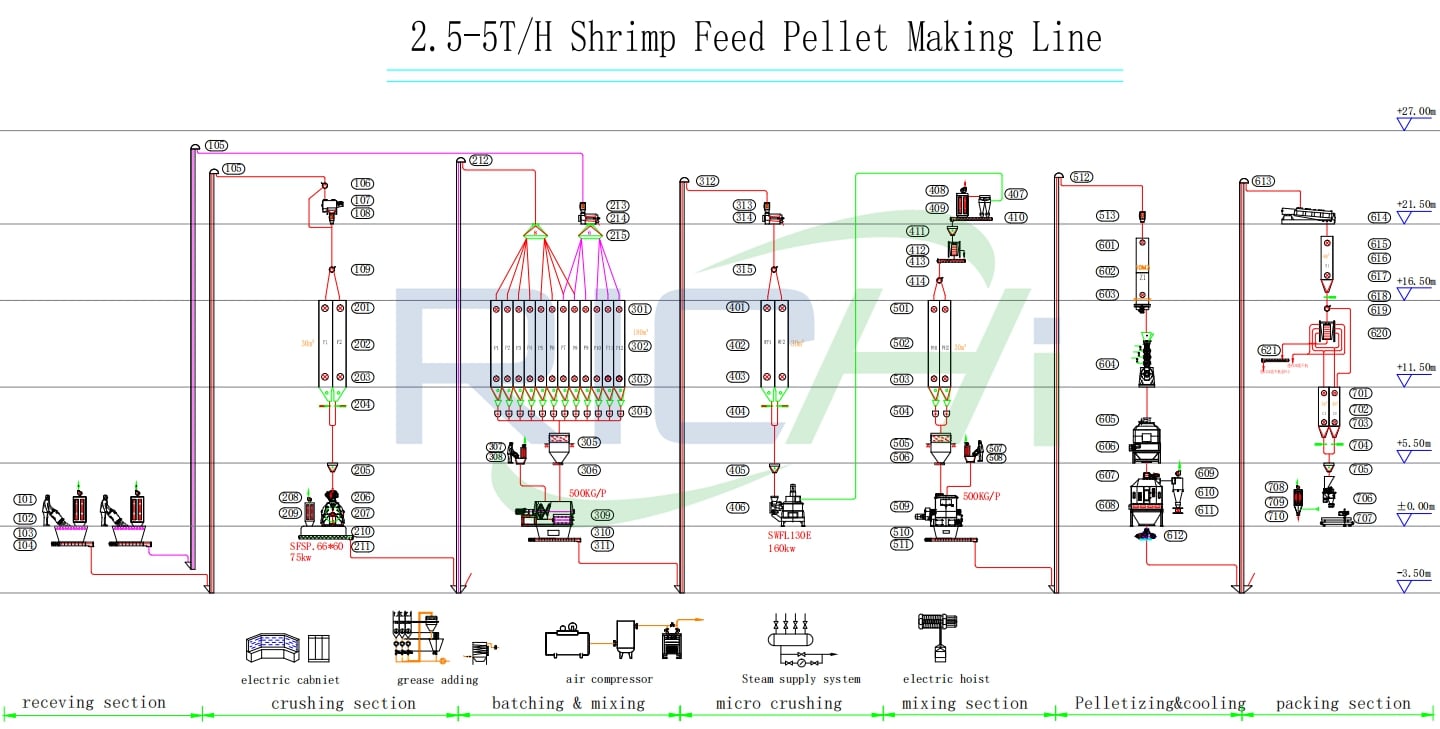

Technology key points of shrimp feed production process

— Richi Machinery —

In order to obtain high-quality shrimp feed pellets, we not only need a high-quality shrimp feed preparation and shrimp feed pellet machine, but also need to crush raw materials and other processes.

Shrimp feed production process:

Raw material receving – rough crushing – batching & mixing – micro crushing – secondary mixing – pelletizing – post-curing – cooling – screening – Final shrimp feed pellet packaging

Technology key points:

- The high-grade shrimp feed manufacturing process usually consists of twice crushing and twice mixing, the first using a drop-type hammer mill to coarsely crush the raw materials, and the second using an ultrafine grinder to crush the shrimp feed to 80-90 mesh. Because the smaller the pulverized particle size of the feed, the larger the reaction during granulation of the feed, the higher the digestibility of the shrimp.

- The curing process after the pelleting section makes shrimp feed particles further gelatinize and mature, and forms a protective film on the surface to improve its palatability, water resistance and digestion and absorption of shrimp.

- The diameter of the shrimp feed pellet is generally 1-3mm, because the size is relatively small, the screening section needs to use a high square plansifter for the screening of the final shrimp feed pellets.

- In addition, the production of 0.6-0.8mm pellets will use a crumbler, the shrimp feed pellet crumbler has the finer lines.

Auxiliary equipment for shrimp feed pellet production

— Richi Machinery —

The auxiliary equipment and the shrimp feed pellet machine together form the shrimp feed pellet mill to complete the efficient production of shrimp feed.

Ultrafine Grinder

Rotary Distributor for Batching

Shrimp Feed Mixing Machine

Shrimp Pellet Crumbler

Pellet Cooler

High Square Plansifter

Fully Automatic Packaging System

Global cases of RICHI shrimp feed pellet machine

RICHI shrimp feed pellet machine has been exported to Ecuador, India, Vietnam, Indonesia, Thailand, Malaysia, the Philippines, Myanmar and other countries, the comprehensive output of these shrimp feed mills more than 100T/H.

1T/H shrimp feed pellet machine in India

2T/H sinking fish feed machine in Thailand

2T/H shrimp feed pellet mill in Indonesia

1T/H prawn feed manufacturing machine in Ecuador

WHY CHOOSE RICHI?

RICHI Machinery – China’s most professional shrimp feed equipment manufacturer. Firmly believe in the power of the brand.

Excellent Product

Our shrimp feed machines and other aquatic equipment have passed CE, ISO certification, and the materials and processes are very careful. We strive to provide customers with the ideal product.

Customized Product

RICHI can customize single machine products, production sections, production processes, production lines, shrimp feed mills, etc. Just tell us your needs and you can customize your own personalized products.

Diverse Products

We not only have shrimp feed pellet machine and complete equipment, but also steel frame, silo, drying machine, other animal feed pellet equipment, biomass pellet machine, etc. Can cover your pellet production needs.

One-stop Service

RICHI has been trying to create benefits and convenience for customers as much as possible, and can achieve one-stop service from factory to factory. We have successfully served 127+ countries and 2000+ customers.

500+

500+ device models

1000+

1000+ turnkey projects

127+

127+ countries and regions

2000+

2000+ customers