Rabbit pellet making machine

Rabbit pellet making machine is the main equipment of rabbit feed pellet mill, which can be used to produce complete rabbit feed pellet with comprehensive nutrition, convenient storage and good palatability. With the increase in demand for rabbit feed pellets, rabbit pellet machine has also become a very popular machine. Then, for rabbit pellet feed manufacturers, it is very important to find reliable rabbit feed pellet production equipment manufacturers.

RICHI rabbit feed pellet making machine for sale

RICHI rabbit feed pellet machine is a ring die animal feed pellet press developed and produced by RICHI Machinery, its capacity ranges from 1 tons per hour to 42 tons per hour, can be used for 0.7-100T/H rabbit feed pellet production line.

RICHI SZLH series rabbit pellet machine is widely used, can process corn meal, wheat bran, soybean meal, grass meal, straw meal, premix, additives, flavoring agents and other types of raw materials.

- Models: SZLH250, 320, 350, 420, 508, 558, 678, 768, 858, etc.

- Price range: $7,000-$100,000

- Capacity: 1-45T/H

- Main power: 22kw-355kw

- Pellet diameter: 2-12mm

- Type: ring die pellet machine

- Customizable: Yes

RICHI’s rabbit feed pellet making machine can not only produce meat rabbits, pet rabbits and other rabbit feed pellets, but also produce chickens, ducks, pigs, cattle, sheep, and other livestock and poultry feed pellets. Please tell us your raw material and feed pellet requirements.

Parameter and price of RICHI rabbit pellet making machine

Next, let’s have a detailed look at the specific model, capacity, parameters and price of the RICHI SZLH series rabbit feed pellet making machine.

SZLH250 rabbit pellet making machine

- Capacity: 1-2T/H

- Main motor power: 22kw

- Feeder power: 1.1kw

- Conditioner power: 1.5kw

- Ring die diameter: 250mm

- Final pellet diameter: 2-12mm

- Price range: 7,000 -10,000 US Dollars

SZLH320 rabbit pellet machine

- Capacity: 3-4T/H

- Main motor power: 37kw

- Feeder power: 1.5kw

- Conditioner power: 2.2kw

- Ring die diameter: 320mm

- Final pellet diameter: 2-12mm

- Price range: 15,000 -20,000 US Dollars

SZLH350 rabbit feed pellet making machine

- Capacity: 5-7T/H

- Main motor power: 55kw

- Feeder power: 1.5kw

- Conditioner power: 3kw

- Ring die diameter: 350mm

- Final pellet diameter: 2-12mm

- Price range: 20,000 -30,000 US Dollars

SZLH420 rabbit feed pellet machine

- Capacity: 8-12T/H

- Main motor power: 110kw

- Feeder power: 1.5kw

- Conditioner power: 7.5kw

- Ring die diameter: 420mm

- Final pellet diameter: 2-12mm

- Price range: 30,000 -40,000 US Dollars

SZLH508 animal feed pellet making machine

- Capacity: 10-18T/H

- Main motor power: 160kw

- Feeder power: 2.2kw

- Conditioner power: 11kw

- Ring die diameter: 508mm

- Final pellet diameter: 2-12mm

- Price range: 40,000 -60,000 US Dollars

SZLH558 rabbit feed pellet machine for sale

- Capacity: 15-25T/H

- Main motor power: 180kw /220kw

- Feeder power: 2.2kw

- Conditioner power: 11kw

- Ring die diameter: 558mm

- Final pellet diameter: 2-12mm

- Price range: 60,000 -70,000 US Dollars

SZLH678 rabbit feed pellet mill

- Capacity: 20-30T/H

- Main motor power: 220kw /250kw

- Feeder power: 2.2kw

- Conditioner power: 11kw

- Ring die diameter: 678mm

- Final pellet diameter: 2-12mm

- Price range: 70,000 -80,000 US Dollars

SZLH768 rabbit pellet maker

- Capacity: 25-40 T/H

- Main motor power: 250kw /280kw

- Feeder power: 2.2kw

- Conditioner power: 11kw

- Ring die diameter: 768mm

- Final pellet diameter: 2-12mm

- Price range: 80,000 -90,000 US Dollars

SZLH858 rabbit pellet making machine price

- Capacity: 28-45 T/H

- Main motor power: 315kw /355kw

- Feeder power: 2.2kw

- Conditioner power: 15kw

- Ring die diameter: 858mm

- Final pellet diameter: 2-12mm

- Price range: 90,000 -100,000 US Dollars

You can choose the above models according to your own production needs, budget situation, or contact us to customize rabbit feed pellet machine for individual needs.

RICHI MACHINERY

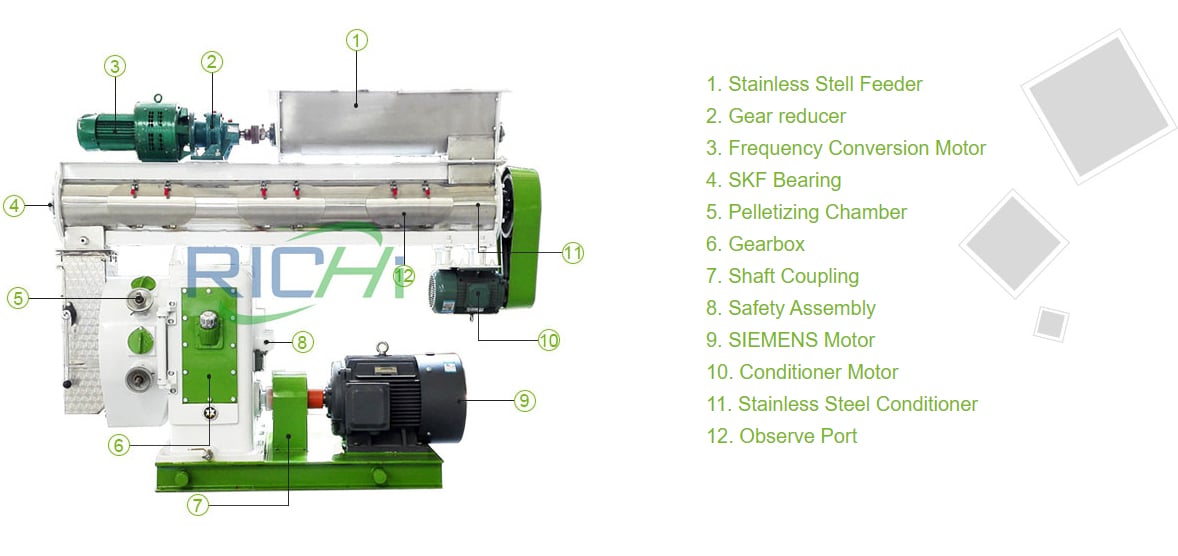

Components of RICHI rabbit feed pellet machine

The machine mainly includes a feeding system, a conditioning system, a granulation chamber and a transmission system. Its main components are Stainless steel feeder, Gear reducer, Frequency conversion motor, SKF bearing, Pelletizing charmer, Gearbox, Shaft coupling, Safety assembly, SIEMENS motor, Conditioner motor, Stainless steel conditioner, Observe port.

working principle of RICHI rabbit feed pellet machine

Feeding system

Stainless steel feeder, gear reducer and frequency conversion motor constitute the feeding system of rabbit feed pellet machine. Under the action of the gear reducer and frequency conversion motor, the powdered rabbit feed enters the conditioner evenly from the stainless steel feeder. Feeding too fast may cause machine blockage, overload shutdown, affect the process of the entire production line. Too slow feeding may cause idling of the machine, which not only wastes power, but also causes wear of the press roll and ring die.

To meet the needs of our customers, our rabbit feed pellet machines can be equipped with Siemens motors, anti-arching feeders and higher and larger feeders.

Conditioning system

Stainless steel conditioner, conditioner motor and SKF bearing constitute the conditioning system of rabbit feed pellet machine. The conditioning time of rabbit feed is generally 10 to 20 seconds. There are blades arranged according to a certain Angle in the conditioner to achieve uniform feed speed, and make the material and saturated dry steam fully mixed. The water content of the modulated rabbit feed is 16% to 18%, and the temperature is 75℃ to 85℃, which is the best state of rabbit feed granulation.

Our conditioners are large size and available in 1, 2 and 3 layers, which can satisfy the production of various animal feed pellets such as poultry, livestock, fish, shrimp, pets, etc.

Granulator chamber

The granulation chamber is composed of stainless steel ring die, press roller, material plate, cutter and other parts. The modulated material enters the granulation chamber from the chute, and the material is sent to the main working area of the granulation chamber by the plate. As the main working parts of the rabbit feed pelletizing machine, the function of the ring die and the press roller is to squeeze the material into the ring die hole to form a high-density columnar feed. At the same time, two cutters on the side of the ring die cut the columnar feed into pellets. The diameter of rabbit feed pellet less than 4mm, its length is 2-5 times the diameter. For rabbit feed pellet with a diameter greater than 4mm, the length is 1.5-3 times the diameter. Both pellet diameter and length can be adjusted or customized as needed.

Transmission system

RICHI rabbit feed pellet machine adopts gear drive, which is 15% more efficient than belt drive. The drive system is mainly composed of Siemens motors, shaft coupling and gearbox.

The drive system is installed on a base, compact structure, small size, smooth operation, low noise.

There is a safety pin device on the gearbox, which can play the role of overload protection for the machine.

Production technology of rabbit feed pellets

The production of rabbit feed pellets is usually carried out in the feed pellet factory, and the production technology in addition to granulation, also includes the crushing of raw materials, batching, mixing, pellet cooling, screening, packaging and so on.

Crushing of raw materials

Main equipment: feed crusher

The raw materials of rabbit feed particles are corn, wheat bran, soybean meal, carrots, green plants and so on. These raw materials first need to be crushed into a powdered feed of 1-4mm. The particle size of the grinding should be determined according to the specific animal, the finer the particle size, the easier it is to gelatinize during the modulation process, the stickier the feed, and the greater the particle hardness.

Batching

Main equipment: batching system

Batching is one of the main steps in the production of rabbit feed pellets, 1-2 tons per hour of rabbit feed production can be manual batching, more than 5 tons per hour of animal feed processing plant usually use PLC batching or automatic batching system. The use of the batching system can not only save labor, but also have higher batching accuracy, making the nutritional content of the feed more accurate.

Mixing

Main equipment: feed mixer

The main function of the mixing section is to mix different raw materials. The feed mixer determines the quality of the mixing process.

The RICHI paddle type feed mixer has a mixing uniformity of 97.7%, no residue, and can mix more than 10 batches per hour. In addition, we have a ribbon belt mixer, suitable for mixing more grass flour, water, molasses, grease materials.

Pelleting

Main equipment: rabbit feed pellet machine

The quality of pelleting process mainly depends on the material conditioning and pressing molding.

The conditioned feed has many benefits for rabbits. First of all, high temperature sterilization kills the bacteria, and the rabbits have a higher survival rate. Second, the cured feed is easier for rabbits to digest and absorb. Third, better taste, better palatability.

The pressed feed pellets are conducive to the rabbit’s feeding and can exercise the rabbit’s teeth.

Pellet cooling

Main equipment: pellet cooling machine

The pellet temperature from the granulator is 70 ° C to 80 ° C, and there is a certain humidity. Direct packaging and transportation is not only easy to break, but also easy to go mouldy. Therefore, we use a counter-current cooling machine to cool the hot and wet feed pellets to room temperature, and the water content is reduced to about 13%. The cooling technology avoids the direct contact between the cold air and the pellets and prevents the cracking of the surface of the pellets caused by sudden cooling.

Screening and packing

Main equipment: pellet screening machine and packing machine

The screening machine will recycle the too large or too small particles in the rabbit feed production, not only to ensure the uniformity of the pellets, but also to save raw materials. The rabbit feed pellets of appropriate size enter the packing system for manual or automatic packing.

After packaging, the rabbit feed pellets are smaller volume, which is conducive to storage, transportation and feeding of rabbits.

Related cases

As part of RICHI animal feed machinery, rabbit feed pellet machine and production line have been recognized by customers around the world, and have been traded with customers in many countries.

10T/H rabbit feed pellet mill in Spain

2T/H rabbit feed pellet making machine in Egypt

50,000 tons per year rabbit feed plant in China

Frequently Ask Question

Frequently Ask Question

Click Here to buy now.

How to choose the right rabbit feed pellet machine?

Choosing the right rabbit feed pellet machine needs to be considered from the aspects of capacity, brand, quality, service and budget.

Rabbit feed pellet machine generally has flat die and ring die, their main difference in capacity. The capacity of flat die pellet machine is generally lower than 1 ton per hour, and the capacity of ring die pellet machine is larger, such as the capacity of RICHI SZLH series in 1T/H-45T/H. For medium and large farms and feed mills, ring die rabbit feed pellet making machines can be decisively selected.

In addition, find reliable suppliers and manufacturers, so as to ensure the quality of the rabbit pellet making machine and the service that businesses can give. If you don’t know how to choose a reliable supplier, you can give priority to merchants with their own factories and their own brands. For example, Henan RICHI Machinery Co., Ltd. is a Chinese brand of feed machinery and equipment business, with two factories in Henan, China, and feed mill customers from all over the world visit and sign orders in the factory every day.

The rabbit feed pellet machine of RICHI Machinery has passed ISO, CE and other certifications, and the quality is guaranteed.

Last but not least, you need to choose according to your budget. Here, RICHI Machinery can customize your own rabbit feed pellet making machine, not only taking into account your budget, but also taking into account your site, capacity, raw materials and other needs. Contact us soon.

Any Question?

You can ask anything you want to know about Feedback