Poultry feed pellet machine price

RICHI SZLH Poultry feed pellet machine prices range from $7,000 to $100,000. Poultry Feed Pellet Machine is a mechanical equipment used to process feed pellets for chickens, ducks, geese, pigeons, etc. It can press the mixed powdered feed into poultry feed pellets.

RICHI MACHINERY

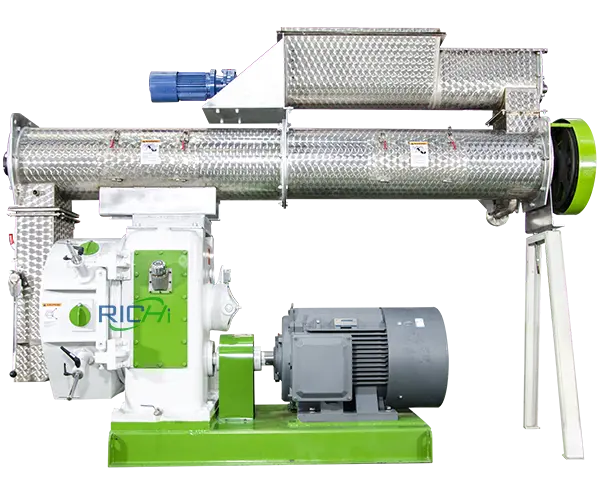

Introduction of RICHI Poultry Feed Pellet Machine

RICHI poultry feed pellet machine is RICHI Machinery’s a hot selling animal feed pellet mill for many years.

Our poultry feed pellet machines are commonly used in poultry feed pellet plant, chicken feed production lines, animal feed pellet plant, animal breeding plant, chicken farm and so on. Because of the high output, low energy consumption, durable, it is widely liked and praised by customers.

- Poultry feed raw materials: corn, wheat, soybean, soybean meal, additives, premixes and so on.

- Capacity: 1-45T/H

- Poultry pellet diameter: 2-12mm

- Applicable animals: chicken, duck, goose, pigeon, quail and other poultry.

- Type: ring die

- Pellet size can be customized: Yes

- Whole machine can be customized: Yes

- Hot Products: SZLH poultry feed pellet machine, SZLH chicken feed pellet machine.

If you are looking for poultry feed pellet machines or the methods to produce poultry feeds, you can contact us.

Advantages of RICHI Poultry Feed Pellet machine

Preferred materials and accessories, constantly optimize the structure design

The conditioner, feeder and ring die which need to contact with materials directly are made of stainless steel, so that the machine won’t be corroded and the feed won’t be contaminated, which has double benefits.

We use Siemens motor, SKF bearings and other first-class brand parts, which makes our machine more stable in operation and have a long life.

In the product design, not only the reasonable structure and beautiful appearance, but also add the humanized design in it. For example, the ring die hoop makes the dismantling of the ring die more convenient, and the safety pin design with overload protection function.

Gear drive: small size, good stability, increase production

The gear box has a compact structural design and small size. Its box adopts casting process, has good stability and long service life. So, our customers reduce the maintenance frequency and replacement cost of poultry feed pellet machine.

The main drive adopts high efficiency gear transmission, which increases its capacity by 15% compared with the belt type. As a result, the capacity of the poultry feed pellet machine is greatly increased with the same energy consumption, which improves the efficiency of the whole poultry feed production line. Eventually, the poultry feed pellet plant’s revenue increases and a sustainable virtuous cycle is realized.

Larger conditioner: improving pellet quality and capacity

RICHI’s poultry feed pellet machines are equipped with larger conditioners, corn, soybeans, soybean meal and other raw materials can be matured, gelatinized and sterilization more fully. As a result, the final feed pellets are more digestible for the animals and less susceptible to infection. Ultimately, this increases the growth rate and survival rate of the animals.

In addition, the modulation of raw materials has the effect of increasing the capacity of feed pellets. Because the materials are mixed with steam, they are easier to be extruded from the die holes, and thus the capacity will be increased.

Customized Animal Feed Pellet machine

As our customers come from all over the world, they will not have the same requirements in terms of raw materials, power consumption, machine performance, production capacity and pellet size, pellet quality and so on. Therefore, providing customers with customized machinery and personalized solutions has become one of RICHI’s features.

For example, feeding different animals requires different sizes of feed pellets. In this case, RICHI can provide customers with ring dies with different aperture diameters, such as 2mm, 4mm, 8mm, 12mm, etc. By replacing the ring dies, feed pellets with different diameters can be produced. If you have any needs, please let us know, we will be glad to help you.

RICHI MACHINERY

Models of RICHI SZLH poultry feed pellet machine

SZLH250 poultry feed pellet machine for sale

- Capacity: 1-2T/H

- Main motor power: 22kw

SZLH320 pellet making machine for poultry feed

- Capacity: 3-4T/H

- Main motor power: 37kw

SZLH350 poultry feed pellet making machine

- Capacity: 5-7T/H

- Main motor power: 55kw

SZLH420 poultry feed pellet mill for sale

- Capacity: 8-12T/H

- Main motor power: 110kw

SZLH508 chicken feed pellet machine for sale

- Capacity: 10-18T/H

- Main motor power: 160kw

SZLH558 chicken feed pellet maker

- Capacity: 15-25T/H

- Main motor power: 180/220kw

SZLH678 broiler chicken feed making machine

- Capacity: 20-30T/H

- Main motor power: 220/250kw

SZLH768 chicken feed pellet making machine

- Capacity: 25-40T/H

- Main motor power: 250/280kw

Parameter Table of RICHI SZLH Poultry Feed Pellet Machine

| Model | Capacity(T/H) | Main Motor Power(kw) | Feeder Power(kw) | Conditioner Power(kw) | Finished Pellet Diameter(mm) |

| SZLH250 | 1-2 | 22 | 1.1 | 1.5 | 2-12 |

| SZLH320 | 3-4 | 37 | 1.5 | 2.2 | 2-12 |

| SZLH350 | 5-7 | 55 | 1.5 | 3 | 2-12 |

| SZLH420 | 8-12 | 110 | 1.5 | 7.5 | 2-12 |

| SZLH508 | 10-18 | 160 | 2.2 | 11 | 2-12 |

| SZLH558 | 15-25 | 180/200 | 2.2 | 11 | 2-12 |

| SZLH678 | 20-30 | 220/250 | 2.2 | 11 | 2-12 |

| SZLH768 | 25-40 | 250/280 | 2.2 | 11 | 2-12 |

| SZLH858 | 28-45 | 315/355 | 2.2 | 15 | 2-12 |

Poultry feed pellet machine test run

This is a simple test run video of a single poultry feed pellet machine. What we can see is that the raw materials are crushed and mixed with corn, wheat, soybeans and so on, and then the worker feeds the powdered feeds directly into the inside of the granulation chamber from the side opening of the granulation chamber, and the made pellets discharge. Pellet molding has been very good.

So what is the specific working principle of poultry feed pellet machine in the real production process?

Powdered feed will first pass through the frequency converter feeder, into the conditioner. The conditioner is connected to the boiler, through the steam, steam and materials are fully mixed. There are paddles in the conditioner, which not only can play the role of mixing, but also send the modulated materials into the chute. Through the chute, materials enter into the granulation room. Inside the granulation chamber, the rollers and ring die extrude the materials, and finally the columnar feeds are extruded from the die holes and cut into the desired length by the cutter. The final feed pellets are discharged.

Advantages of RICHI Machinery

RICHI has been in the feed machinery industry for 30 years, and already has obvious advantages in price, quality, experience and service.

Price Advantage

First of all, as the production cost in China is lower compared with other countries, this is the general environment advantage. Secondly, we have our own factory, no middleman to extract the price difference, to ensure that we can give customers the most original ex-factory price. Thirdly, we are willing to make profits for customers to realize a win-win deal. In the end, let the customer get the most cost-effective products, get the due revenue.

Quality Advantage

As the most professional feed machinery manufacturer and exporter in China, we have skillful technology and advanced production equipment, and we strive for excellence in our production process. In addition, we will always establish contact with our customers the moment we start the transaction, so that they can also participate in the supervision process of our machinery and equipment production. Ultimately, to ensure the quality and time of product delivery.

Experience Advantage

RICHI has set up poultry feed pellet production lines in America, Germany, Thailand, Malaysia, Indonesia, Philippines, Uzbekistan, Zimbabwe, Canada, UK and other 127 countries and regions, among which poultry feed pellet mills as the main equipment are also followed and sold to all over the world. Experiencing so many projects, we have established a perfect program to solve the problems that customers often encounter.

Service Advantage

RICHI provides customers with project consulting, program design, equipment selection, equipment production, delivery, installation and commissioning to training and after-sales “turnkey” service. We can make the whole process worry-free for our customers.

We provide customers with information such as quotations, delivery lists, flow charts, equipment layout diagrams, steel structure diagrams, installation manuals, operation manuals and so on.

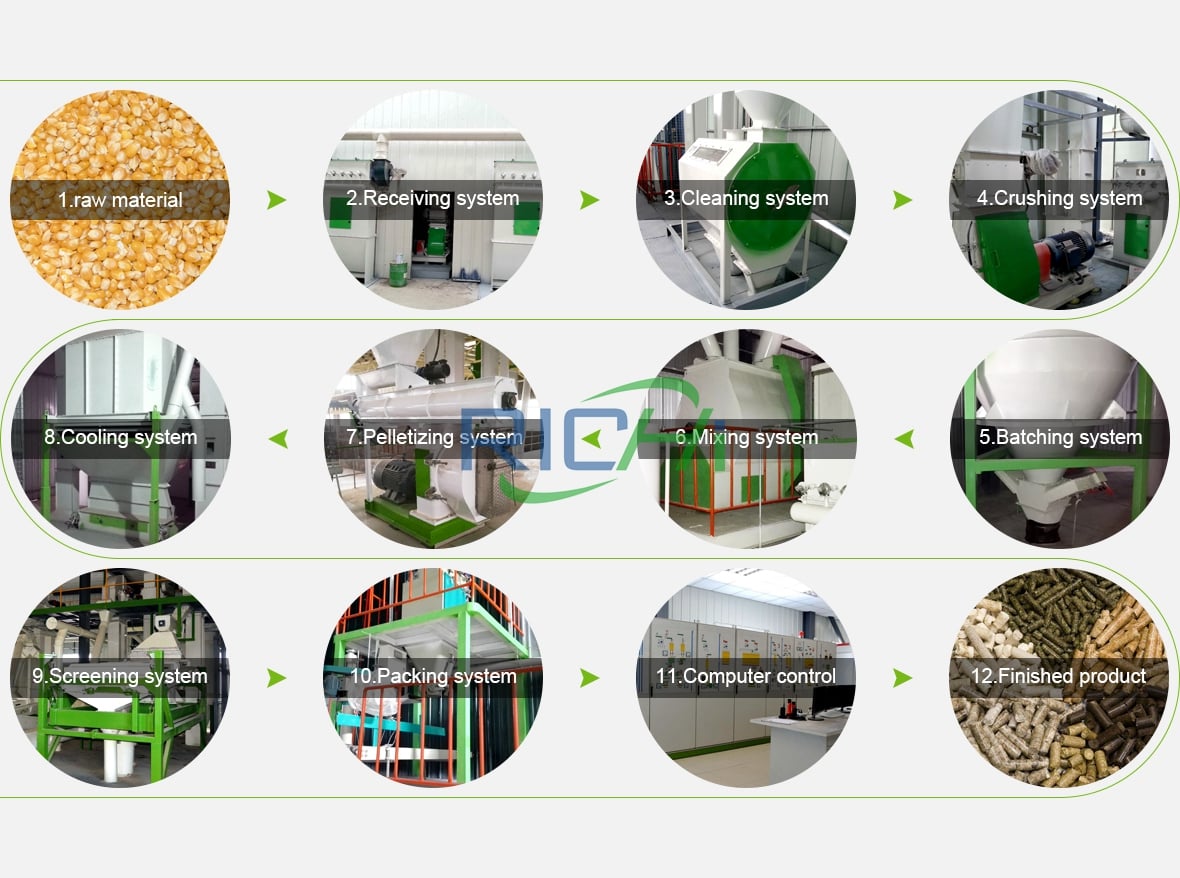

The whole process of poultry feed pellet production

Preparation of raw materials – Receviving- Removing of impurities – Crushing – batching – Mixing – Pelleting – Cooling – Crumbling – Sieving – Packaging

These sections can form a complete poultry feed pellet production line. The selection of each of these sections can also be adapted to the needs of the customer.

Large quantities of corn, wheat and other raw materials storage can be considered silo. If the raw material is powdered feed, the pulverizing section can be omitted. If you want to save batching labor and improve batching accuracy, you can choose PLC batching or automatic batching system. Contact us for more detailed design of poultry feed pellet production program.

- Capacity of poultry feed pellet production line: 1-100T/H

- Price: 10,000-2,800,000USD

- Main Equipment: Grain hammer mill, feed mixer, Poultry Feed Pellet Machine, Feed Pellet Cooler, Automatic Packing Machine, Conveying Equipment, etc.

● RICHI MACHINERY

Customer Cases

10T/H animal feed processing plant

- Price: $200,000-$350,000

- Country: Uzbekistan

- Project total power: 520kw

- Raw materials: corn, wheat, sunflower seeds, premix, oil, etc.

- Main equipment:SFSP Hammer mill (66*80, 110kw), Automatic Batching System,Animal feed mixer (1T/P), SZLH 420 animal feed pellet machine, SKLN Cooler (20×20), Packing machine, etc.

- Customer Feedback: “good day! I am very glad to hear to you! Say hello to everyone. We have finally launched our line! Everything works fine. I am sending you a video of our factory.”

3-4T/H Chicken Feed Pellet Production Line

- Price:$50,000-120,000

- Country:Zimbabwe

- Project total power: 118kw

- Customer’s main raw material: corn

- Main Equipment: 37KW hammer mill, feed mixer, 37KW SZLH chicken feed pellet machine, pellet cooler, coal-fired boiler

- Customer’s visit: The customer came to China, visited our factory and had a face-to-face communication with us. They are satisfied with our product quality and service.

1-2T/h chicken feed production line

- Price:$10,000-$50,000

- Country:Tanzania

- Project total power: 47.95kw

- Customer’s raw material: corn, wheat, soybean meal, etc.

- Main equipment: grain hammer mill, feed mixer, SZLH250 chicken feed pellet machine, cooling belt

Frequently Ask Question

Frequently Ask Question

Click Here to buy now.

What are the advantages of poultry feed pellets made by poultry feed pellet mill?

Poultry feed pellets are a kind of complete feed pellet that contain the calories, protein, and microelements that poultry animals need. They have the advantages of complete formula, rich nutrition, easy to digest and easy to store. Poultry feed pellets are high quality feeds for ducks, geese, pigeons and other animals, especially, they are the main feed for chicken farms.

What is the poultry feed pellet machine price in Nigeria?

A single RICHI poultry feed pellet machine price is 7,000-100,000 US dollars. There are SZLH250, SZLH320, SZLH350, SZLH450 models available, with the capacity ranging from 1T/H to 45T/H, and the diameter of poultry pellets are 2mm, 4mm, 6mm, 8mm, 10mm, 12mm, etc. You can choose different models according to your needs, of course, their prices are different.

If you want to customize your own poultry feed pellet mill, then the price will also different. If you want to get the specific price, send inquiry to tell us your raw material, capacity requirement, desired feed pellet size, etc., we can give you the specific model and price list.

In addition, customers from any countries and regions can send inquiry to us, our sales staff will give you the lowest price we can do.

Any Question?

You can ask anything you want to know about Feedback