Pig feed pellet machine

Pig feed pellet machine is the main equipment for the production of pig feed pellets, which is very common in pig feed pellet plant and feed machinery industry. High quality and efficient pig feed pellet making machine can improve the production capacity and quality of pig feed, but also improve the economic benefits of pig feed pellet plant.

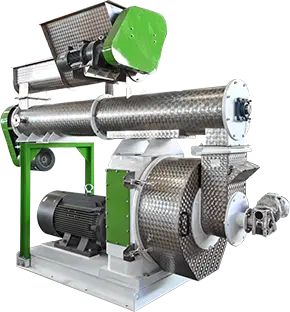

Efficient SZLH pig feed pellet machine from RICHI Machinery

With high quality, reasonable price, broad applications, customized solutions and turnkey services, RICHI SZLH pig feed pellet mills are very popular in the feed pellet plants around the world.

RICHI SZLH pig feed pellet machines are developed according to the characteristics of pig feeds, can produce different sizes and different ingredients of pig feed pellets.

- Guide price: 7,000-100,000 US Dollars

- Capacity: 1-45T/H

- Pellet diameter: 2-12mm (pig feed pellets are usually 2-5mm)

- Raw Materials: Corn, wheat, broken rice, soybean meal, cottonseed meal, rapeseed meal, soybean husk, oil bran, fish meal, flour, wheat bran, weeds, alfalfa, premix, additives, etc.

- Applications of pig feed pellets: nursery pigs, piglets, fattening pigs, large pigs, pregnant sows, milking sows, swine, hog, boar and other pigs.

- Applications of pig feed pellet machine: pig feed mill, poultry and livestock feed plant, pig farms, etc.

- Type of the pig feed making machine: ring die pellet machine

- Ring die compression ratio: 1:3.5-1:13. (Ring die compression ratio refers to the ratio of the effective thickness of the ring die to the minimum diameter of the ring die hole, and the production of pig feed pellets usually adopts 1:3.5-1:8. The larger the compression ratio, the stronger the pig feed pellets.)

- Features: Customizable, equipped with conditioner

Advantages of RICHI SZLH pig feed pellet machine

High-quality and efficient of RICHI SZLH series pig feed making machines benefit from their good structure design, materials and accessories.

Stainless steel materials, corrosion resistant, more durable

Feeder, conditioner, feed chute, ring die, door of pelletizing room and other sections in direct contact with pig feeds are all made of high-quality stainless steel materials. Avoid pig feed making machine rust and pig feed deformation. The stainless steels themselves are durable and easy to c. So, RICHI SZLH pig feed pellet machine is stronger, has longer service life and can produce higher quality pig feed pellets.

Compact structure, small size, high output

The connection between the gear box and the motor of SZLH pig feed making machine adopts compensation serpentine spring coupling with international advanced level, which makes pig feed machine has compact structure, smaller size and low failure rate. Besides, the efficient of gear drive is higher. So, saving pig feed mill space and improving the capacity of pig feed production line.

Original accessories

Original accessory is one of the characteristics of RICHI Machinery, which has multiple benefits. First of all, the original accessories are more compatible with the SZLH pig feed making machine, making the machine performance more stable. Second, RICHI factory has strict control and test for each original part, the quality is guaranteed. Third, can meet the customer’s parts replacement needs.

Customizable ring die

Ring die is one of the main components of poultry feed pellet machine, which determines the capacity, size and hardness of pig feed pellets. Among them, the larger the diameter of the ring die, the larger the output. The diameter of the ring die hole is the diameter of the pig feed pellet. So, we will provide customers with 2mm, 2.5mm, 3mm, 4mm, 5mm ring dies, to meet the production needs of different pig feed pellets. And, we can customize according to the needs of customers.

RICHI SZLH series pig feed pellet machine for sale

Based on the capacity commonly used by our customers, we have launched 8 pig feed pellet mills models with the capacity ranging from 1 to 45 tons per hour.

SZLH250 pig feed making machine for sale

- Capacity: 1-2T/H

- Main power: 22kw

- Pellet Size: 2-12mm

SZLH320 pig feed machine

- Capacity: 3-4T/H

- Main power: 37kw

- Pellet Size: 2-12mm

SZLH350 pig feed mill

- Capacity: 5-7

- Main power: 55kw

- Pellet Size: 2-12mm

SZLH420 pig feed pellet machine for sale

- Capacity: 8-12

- Main power: 110

- Pellet Size: 2-12mm

SZLH558 poultry feed pellet machine

- Capacity: 15-25T/H

- Main power: 180/200kw

- Pellet Size: 2-12mm

SZLH678 chicken feed pellet making machine

- Capacity: 20-30T/H

- Main power: 220/250kw

- Pellet Size: 2-12mm

SZLH768 animal feed pellet mill

- Capacity: 25-40T/H

- Main power: 250/280kw

- Pellet Size: 2-12mm

SZLH858 pig feed pellet mill

- Capacity: 28-45T/H

- Main power: 315/355kw

- Pellet size: 2-12mm

Parameter table of RICHI SZLH pig feed pellet machine

| Model | Capacity(T/H) | Main Motor Power(kw) | Feeder Power(kw) | Conditioner Power(kw) | Finished Pellet Diameter(mm) |

| SZLH250 | 1-2 | 22 | 1.1 | 1.5 | 2-12 |

| SZLH320 | 3-4 | 37 | 1.5 | 2.2 | 2-12 |

| SZLH350 | 5-7 | 55 | 1.5 | 3 | 2-12 |

| SZLH420 | 8-12 | 110 | 1.5 | 7.5 | 2-12 |

| SZLH508 | 10-18 | 160 | 2.2 | 11 | 2-12 |

| SZLH558 | 15-25 | 180/200 | 2.2 | 11 | 2-12 |

| SZLH678 | 20-30 | 220/250 | 2.2 | 11 | 2-12 |

| SZLH768 | 25-40 | 250/280 | 2.2 | 11 | 2-12 |

| SZLH858 | 28-45 | 315/355 | 2.2 | 15 | 2-12 |

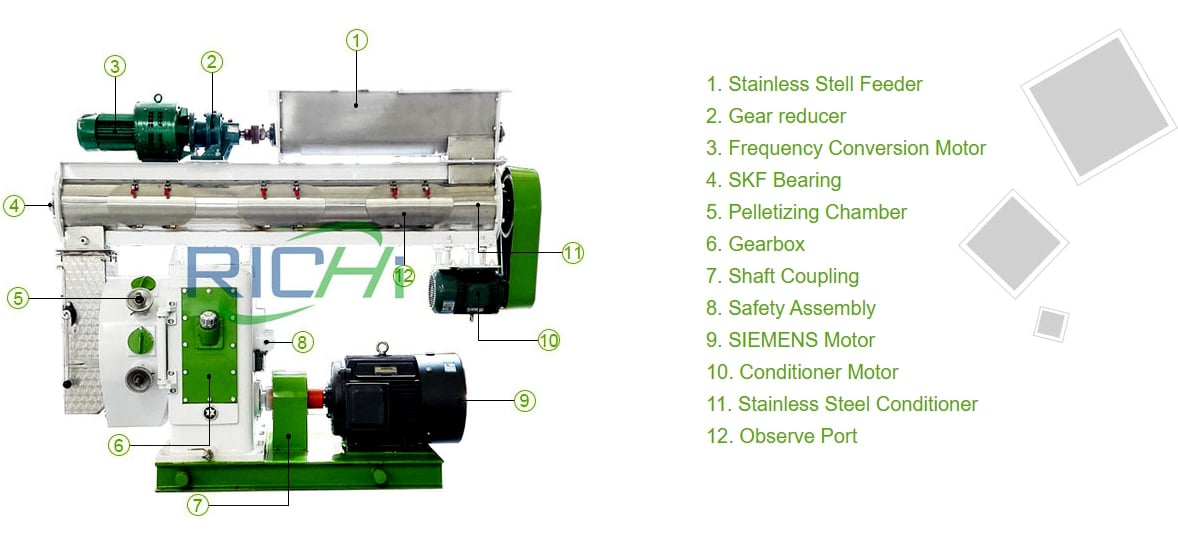

What are the componments of RICHI pig feed pellet machine? how does it work?

The main components of Richi pig feed pellet making machine: variable frequency feeder, stainless steel conditioner, feed chute, granulation chamber (feed switch plate, ring die, rollers, cutter), gear box, Siemens motor.

Work principle: The mixed powdered pig feed is uniformly fed into the stainless steel conditioner through a variable frequency feeder. The conditioner has an orderly arrangement of blades inside, which can fully mix the material with the steam and push the material into the feed cute. Pig feed goes through feed cute to the pelletizing chamber. Then, the feeder switch plate transfers the prepared pig feed to the ring die and press rollers. The high-speed rotating ring die and rollers extrude the pig feed from the die holes to form a high-density columnar pig feed. And then cut into pig feed pellets.

- Powdered pig feed moisture: about 15%

- Modulation temperature: 70℃-80℃

- Modulation time: 15s-40s

- The specific parameters are set according to the needs of pig feed pellets, you can immediately send inquiries to consult us.

● RICHI MACHINERY

Why produce pig feed with a pig feed pellet machine?

With the huge pig industry, people’s requirements for pig feed are getting higher and higher. Convenient, nutritious and delicious pig feed pellets have become the favorite of modern pig factories.

Rich and comprehensive nutrition

Pig feed pellet press has a wide range of raw materials, which can mix energy, protein, vitamins, oils and forage raw materials to make high-density pig feed pellets. Therefore, the nutrition of pig feed pellets is more comprehensive and cannot be picked, which is conducive to the rapid growth of animals.

Easy to store and feed

Pig feed pellets are solid and denser. Take up less space in both storage and transport. Compared with powder feed, pellet feed is not easy to produce classification. In modern pig plants, automated feeding is also more suitable for pig feed pellets. So, the pig feed pellet machine makes it easier for pig farmers.

conducive to digestion and absorption of pigs

Pig feed pellets are modulated by steam and high temperature in the production process, and the cured feed is more conducive to digestion and absorption of pigs. For pigs, gelatinized feed pellets are more palatable. In addition, high temperature modulation will also kill germs, which is beneficial to the health of pigs.

Pig feed pellet manufacturing process and equipment

The mass production of pig feed pellets needs a production line to complete, which uses the feed grinder, pig feed mixer, pig feed machine, pig feed pellet cooling machine, automatic packing machine and so on.

Delivery of raw materials

Main equipment: feed port

According pig feed ingredients, feeding corn, soybean cake, fish mash, wheat bran, etc.

Crushing of grain raw materials

Main equipment: Grain hammer mill

Crushing corn, wheat, soybean cake, sunflower seed into powders.

Mixing of powder pig feeds

Main equipment: feed mixing machine

Mixing of corn meal, wheat flour, soybean meal, fish meal, premix, oil, additives.

Pelletizing

Main equipment: Pig feed pellet machine

Pelletizing mixed mash pig feed into pig feed pellets.

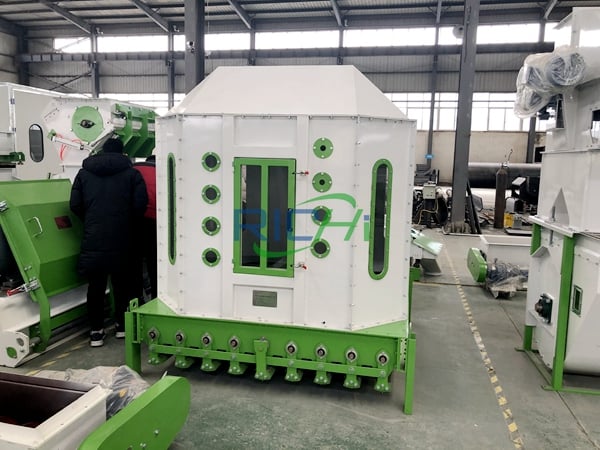

Cooling

Main equipment: pig feed pellet cooler

Cooling 80℃ pig feed pellets into workshop temperature.

Packing

Main equipment: Automatic packing system

Automatic weighting, packing and sewing of final pig feed pellets.

What can RICHI do for your pig feed business?

Henan RICHI Machinery Co., Ltd. has been deeply engaged in the feed machinery industry for 30 years, and is the most professional supplier and manufacturer of pig feed machines in China. RICHI can provide you with a comprehensive service.

Pig feed pellet production solution

Customization of the pig feed production line: from customer’s raw materials to final pig feed pellets required by customers.

For the same raw material and pellet requirements, the solution is mainly designed for the customer’s budget, plant location and local conditions.

livestock feed pellet mill manufacture

RICHI is not only a supplier and exporter of livestock feed pellet mill, but also a manufacturer. We have the largest pellet machinery factory in Henan Province, China, and its production technology, manufacturing process and production equipment are world-class.

Pig feed plant renovation

We can renovate and upgrade the feed line in the original pig feed mill for our customers. In 2020, our pig feed plant renovation project with an annual output of 20 tons in China will transform 5 pig feed production lines into 4 pig feed pellet production lines and 2 aquatic feed pellet production lines.

Pig feed plant building

We can also build new pig feed plants for customers, mainly responsible for pig feed pellet production line layout, equipment installation and commissioning, worker training and so on. We can provide you with project layout diagram, production line layout diagram, equipment layout diagram, equipment installation diagram, etc.

If you have the any need, please contact us soon.

RICHI pig feed pellet machine cases

RICHI has sold pig feed machines to the world, and established poultry and livestock feed plants for customers in 127 countries around the world.

Pig feed mill in Hunan province, China

- Project time: Feb, 2020

- Country: China

- Capacity: 20T/H

Livestock feed pellet mill in America

- Country: America

- Capacity: 20T/H

- Main animal: cattle

Poultry feed pellet plant in Africa

- Project time: April, 24,2023

- Country: Nigeria

- Capacity: 1-2T/H

You may also like

Pig feed pellet machine can not only produce pig feed pellets, but also produce other poultry and livestock feed pellets by changing the feed formula.

Frequently Ask Question

Frequently Ask Question

Click Here to buy now.

How much is the price of pig feed pellet machine?

$7,000-$100,000. The price of RICHI pig feed pellet machine is cheaper than the same type, but our quality is guaranteed.

Our cost savings are in promotion, operation, etc. More energy is used in the R&D and manufacturing of equipment.

We do cross-border B2B business, our pig feed pellet machine and other equipment from our own factory, do not need agents to earn the difference.

You can ask anything you want to know about Feedback