PELLET PLANT SOLUTION

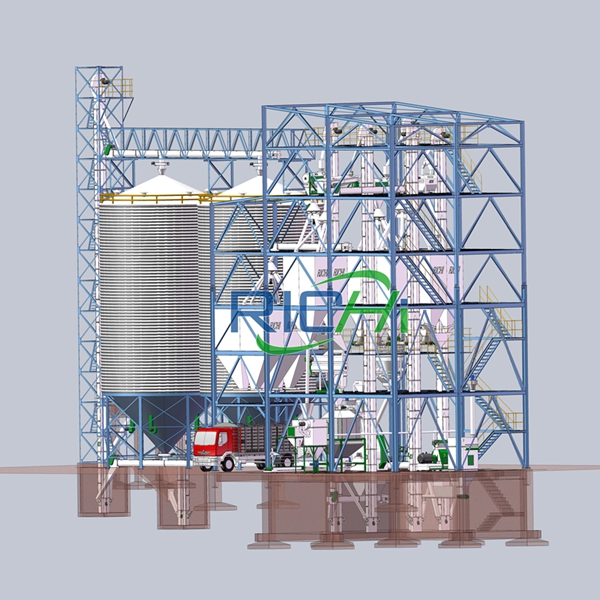

Are you struggling to figure out how to build a pellet plant? It may be an animal feed pellet plant, biomass pellet plants, a wood pellet mill, or any other organic pellet production plant. Then, RICHI Machinery can provide you with practical and efficient pellet process plant solutions.

RICHI Pellet Plant Solution

Henan RICHI Machinery Co., Ltd. is a company from Zhengzhou, Henan, China, which has been established for 30 years. We have provided solutions to build pellet processing plant for more than 2000 customers in 127 countries around the world. Now, we have rich experience, first-class technical team, mature pellet equipment manufacturing factory, perfect service system. Ultimately, these ensure that we can provide our customers with cost-effective, high quality and efficient pellet plant solutions.

The important thing is, the purpose of pellet production plant solutions is to achieve the desired pellet production capacity and quality, while saving costs and rational use of plant space. So, in order to solve the needs of customers in the construction of pellet plants and the actual pellet production process, RICHI Machinery will provide customized pellet production solutions for each customer.

Can’t find a suitable pellet plant solution?

Contact us to customize for you

Customizable Solutions

—— RICHI MACHINERY ——

You can choose according your raw materials, pellet types, capacity, budget, plant size.

Capacity: 1-100T/H

Suitable for 2-18mm poultry, livestock, ruminant feed pellet production.

Fish Feed Production Line

Capacity: 0.5-60T/H

Suitable for floating fish , sink fish, shrimp feed pellet production.

Capacity: 0.5-40T/H

From biomass to bio-fuel. Suitable for 6-12mm wood, straw, shell pellet production.

Capacity: 0.5-45T/H

From biomass to bio-fuel, organic fertilizer, or feed pellets.

FAQ: Can RICHI pellet equipment produce other pellets?

Yes. RICHI Machinery has been committed to providing customers with turnkey solutions for the development, manufacturing, sales and installation of complete pellet production equipment. In addition to the above animal pellets, fish feed pellets, wood pellets, biomass pellets, straw pellets, organic fertilizer pellets, our pellet equipment can also process pest poison pellets, such as snail pellet, rat poison pellet; tire fiber pellet and other pellets. As long as your main raw materials are organics, and you want to process into pellets or powder, you can contact us.

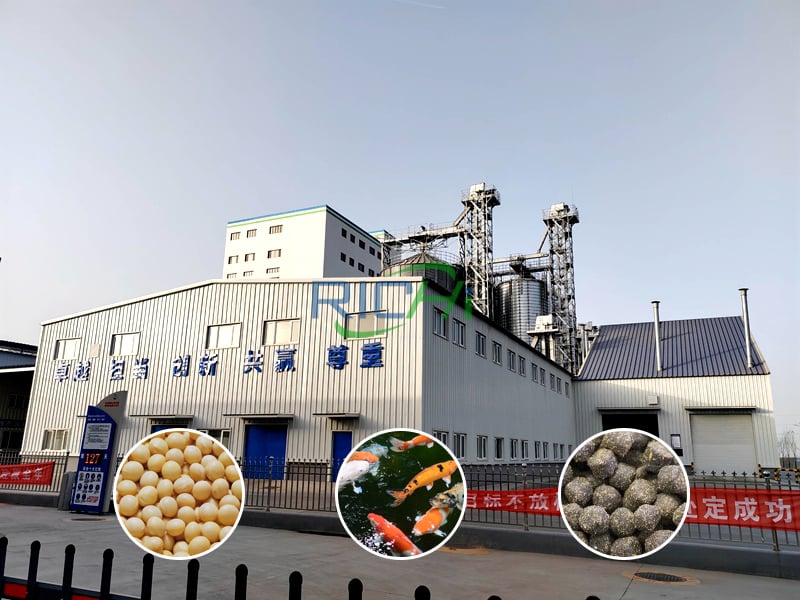

1-100T/H Animal Feed Pellet Plant

You can build a feed pellet line for a kind of animal feed pellet according to your needs, or you can customize a compound line for the production of two or more kinds of animal feeds.

Poultry Feed Pellet Plant

Chicken, duck, goose,etc. feed pellet production.

Livestock Feed Pellet Mill

Pig, cattle, sheep, horse,etc. feed pellet production.

Chicken Feed Production Line

Main raw materials are grains, such as corn, wheat, and soybeans.

Automatic Cattle Feed Plant

Ruminant feed pellets production for cow, bull, beef cattle, dairy cattle.

Pig Feed Plant

Suitable for mash feed, pellet or premix production.

Rabbit Feed Pellet Mill

Suitable for grass-containing feed pellets production.

Premix Plant

Suitable for the processing of animal feed additives.

Compound Line for Mutiple Feeds

Different animal feed pellets or mash and pellet feeds.

Price Range of Building an Animal Feed Production Line

Animal feed pellet plant raw materials are wheat, corn, soybean, rapeseed meal and other grains, alfalfa grass, straw and other grasses. It can produce feed pellets for various animals. More importantly, there are multiple different solutions for the same capacity of animal feed production line, which mainly takes into account the customer’s budget and plant size. We want to help each customer find a satisfactory animal feed production line.

| Capacity | Price | Plant Size |

|---|---|---|

| 1-2T/H | $10,000-$50,000 | customizable |

| 3-4T/H | $50,000-$120,000 | customizable |

| 5-7T/H | $70,000-$250,000 | customizable |

| 8-10T/H | $150,000-$300,000 | customizable |

| 12-20T/H | $250,000-$580,000 | customizable |

| 25-40T/H | $450,000-$850,000 | customizable |

| 50-60T/H | $900,000-$1,400,000 | customizable |

| 60-80T/H | $1,450,000-$1,800,000 | customizable |

| 80-100T/H | $2,000,000-$2,800,000 | customizable |

FAQ: Why do production lines with the same capacity have different prices?

Our production line is customized according to the needs of customers, the production lines with the same capacity will also design a variety of different solutions. Such as manual, semi-automatic, fully automatic, PLC and so on. Of course, our machinery and equipment are of high quality, just for the customer’s different budget and plant size to design different solutions. In addition, the customer’s raw materials are different, the solution will be different. The raw materials on the animal feed line are mainly reflected in the form, such as granular raw materials need to be crushed, and powdered raw materials do not need to be crushed. There are many customers, in the process of pelletizing, packaging and other processes will also be different. Therefore, different design solutions will incur different prices. If you have more questions, you can inquire us.

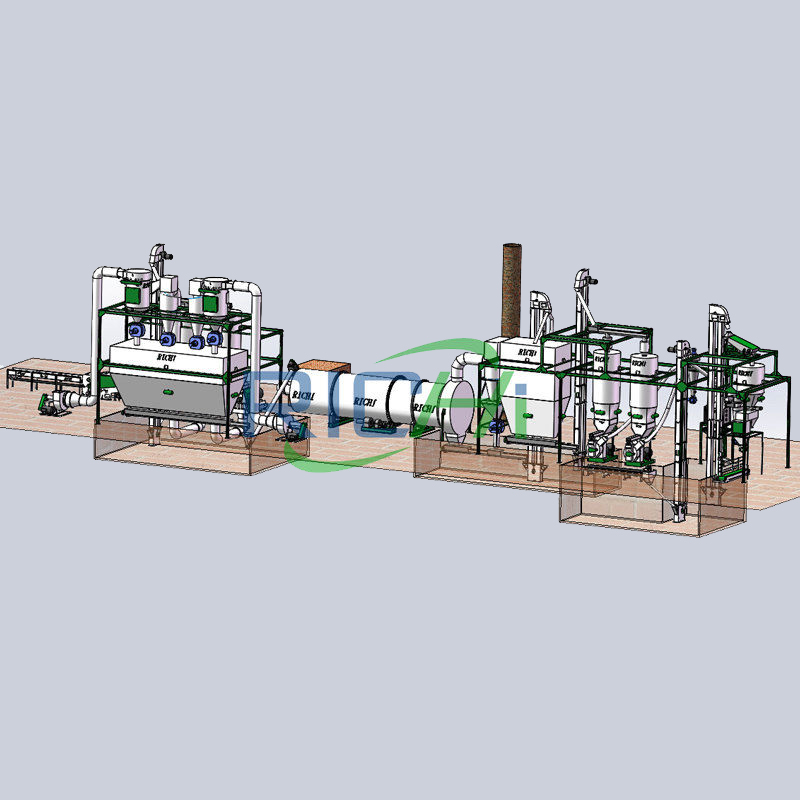

0.5-60T/H Fish Feed Production Line

Fish feed production line is mainly used for the production of aquatic feed pellets, such as sink fish feed, floating fish feed, shrimp feed and so on. We have provided fish feed plant solutions to many customers in coastal areas. These customers earn high returns.

Floating Fish Feed Plant

Main equipment: fish feed extruder machine for extruded feed pellets

Fish Food Production Line

Main equipment: feed pellet machine with 2-layer conditioners

Shrimp Feed Pellet Mill

Main Equipment: feed pellet machine with 3-layer conditioners

Aquatic Feed Plant

Customizable aquatic feed production line for aquatic feed plant.

Pet Food Production Line

Dog, cat, hamster and other pet feed pellet production.

Fish Feed Mill Plant

We are a quality and reliable fish feed mill manufacturer.

FAQ: Why do fish feed and shrimp feed pellet machines need 2-3 layers of conditioners?

The function of the conditioner is to pass steam, sterilize and mature the feed before pelleting, and also improve the yield. So, for aquatic animals like fish and shrimp, their stomachs are more fragile, and we need to have a higher degree of maturation of the feed. Increasing the number of conditioner layers can prolong the modulation time of the powder feed and increase its degree of curing and gelatinization. In addition, RICHI’s conditioner is larger than its peers and is made of stainless steel, which does not pollute the feed. Therefore, our 2-3 layer conditioners can be more conducive to the quality and capacity of fish and shrimp feed pellets.

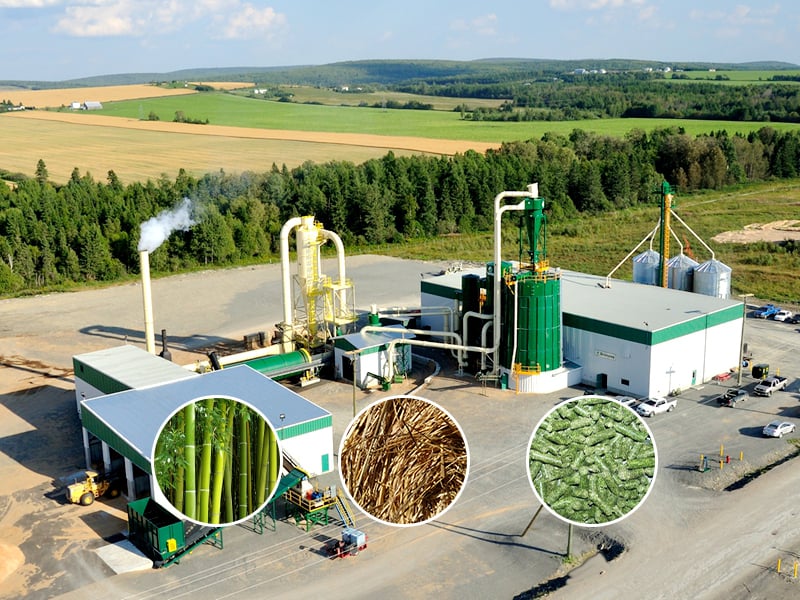

0.5-40T/H Wood Pellet Production Line

From biomass to bio-fuel

Wood Pellet Plant

Turning agricultural and forestry waste into biomass pellet fuel.

Cat Litter Production Line

Suitable for pellet plants with cat litter raw material.

Turnkey Wood Pellet Mill

It is suitable for 6-12 mm wood pellet production.

Price Range of Building a Wood Pellet Production Line

| Capacity | Price | Plant Size |

|---|---|---|

| 0.5-1T/H | $30,000-$80,000 | customizable |

| 1-1.5T/H | $100,000-$200,000 | customizable |

| 2-3T/H | $120,000-$270,000 | customizable |

| 3-4T/H | $200,000-$400,000 | customizable |

| 4-5T/H | $250,000-$450,000 | customizable |

| 6-8T/H | $350,000-$550,000 | customizable |

| 8-10T/H | $300,000-$800,000 | customizable |

| 10-20T/H | $500,000-$1,600,000 | customizable |

| 20-40T/H | $1,000,000-$3,000,000 | customizable |

FAQ: What are the differences between the wood production lines of different solutions?

The raw materials of the wood production line are a wide range of sources, which can be wood chips, logs, bark, branches, wood blocks and other forest waste, corn stalks, wheat stalks, fruit shells and other agricultural waste, grasses, discarded wooden furniture, wooden boxes and so on. We can see that the shape and humidity of these raw materials are very different. Therefore, the difference in the solution of wood pellet production line is mainly reflected in the slicing, crushing and drying sections of raw materials. In the actual solution design, RICHI will be based on the specific situation and budget of customers.

0.5-45T/H Biomass Pellet Plant

From biomass to bio-fuel, organic fertilizer, or feed pellets.

Straw Pellet Production Line

Suitable for 6-12mm straw and other biomass pellets production.

Grass Pellet Production Line

Suitable for fresh grass, bagasse, peanut shell, etc.

Fertilizer Pellet Plant

Suitable for organic manure such as chicken manure and cow dung.

Bamboo Pellet Production Line

Suitable for 0.4-45T/H bamboo pellets production.

Hay Pellet Mill For Sale

Suitable for crushing and granulating of hay.

Alfalfa Pellet Production Line

Suitable for alfalfa, straw, husk and other agricultural waste.

FAQ: What are the processes of a biomass pellet production line?

Processing of raw materials (e.g. chipping of wood, breaking of straw bales, iron removing of wood sawdust) →crushing →drying →homogenizing →pelleting →cooling →packaging. In addition, there will be conveying equipment, dust removal device, electric control cabinet, air pressure system and so on. We will make adjustments according to the needs of customer.

Real Cases of Pellet Plant Solution

127+ /countries and regions

As the world’s first-class manufacturer and supplier of wood pellet equipment, feed machinery complete sets of equipment, aquatic feed production lines, silos, HENAN RICHI MACHINERY Co., LTD. has been exported to 127 countries and regions, and then has won unanimous praise from customers.

2,000+ /SOLUTIONS

We have done more than 2000 pellet plant solutions around the world and have accumulated rich experience in the construction of wood pellet plants. And these projects are located in Europe, Africa, Asia, North America, South America, and Oceania.

Containing 33% Alfalfa Feed Pellet Production Line in Saudi Arabia

5-6T/H cattle feed and 10T/H chicken feed pellets production line, which is customized by RICHI Machinery.

The feed production line was built on March 30, 2018, and the installation period is 90 days. The compound line is used to produce 5-6T/H cattle feed pellets and 10T/H chicken feed pellets, and the finished pellet size is 1-12 mm. The customer’s raw materials are alfalfa, corn and soybean meal, of which 33% is alfalfa in cattle feed. The production line uses automatic computer batching system, oil boiler, grass pellet machine with 160KW, SFSP hammer mill with 110KW, automatic packing system and so on.

1T/H Floating Fish Feed and 1-2T/H Animal Feed Compound Line in UZ

The guide price is $25,000-$150000.

In January 2019, we set up a compound production line for our customers in Uzbekistan for the production of floating fish feed and animal feed. The plant size is 15m*9.5m*8m, the total power is 150kw/h, and the production line needs 6 workers.The pellet plant is suitable for 1-1.2T/H floating fish feed, 1-2T/H chicken feed, 1-2T/H cattle or goat feed pellet production. The machines on the pelletizing section have an floating fish extruder machine with 90KW and a SZLH250 feed pellet machine with forced feeder.

1-1.5T/H Wood Pellet Plant Solution In Iceland

The Icelandic customer chose us because of the quality equipment and suitable wood pellet plant solution.

On November 5, 2015, we set up a 1-1.5T/H wood pellet production line for our customers from Iceland. The plant covers an area of 13m*5m, the height is 6m. The customer’s main raw material is wood sawdust. The customer is used to transform the original wood pellet production line, because the quality of the equipment provided by the original pellet machine manufacturer is relatively poor, and problems are often encountered in the production process, which seriously affects the operation of the plant. Finally, the customer found RICHI Machinery, changed the situation, so that the wood pellet plant was revitalized.

3-5T/H Organic Fertilizer Pellet Mill in Thailand

Customer’s raw materials are chicken manure and rice husk.

On August 27, 2018, we built a 3-5/H organic fertilizer pellet mill for our customers in Thailand. The installation period of this project is 10 days, and we send 2 installation engineers to assist in the installation. The customer’s main raw materials were chicken manure and rice husk, with a final pellet size of 4mm. Plant size is 9m*3m*10m, total power is 80kw/ h. This project is also for the customer to upgrade the product, in this process, we have a good solution to the old equipment and new equipment connection problem.

Why Do Pellet Plants Choose RICHI’s Solutions?

- Our pellet plant solution is supported by our own factory. Designers and technicians communicate without barriers and can do their best to meet the needs of customers.

- We have global 2000+ project experience and can make appropriate solutions for customers’ pain points.

- Our pellet equipment can produce a very wide variety of pellets, including animal feed, fish feed pellets, wood pellets for burning, biomass pellets, organic fertilizer pellets, rat poison pellets, cat litter, tire fiber pellets and more.

- RICHI’s solution is one-stop, committed to saving costs and improving economic efficiency for customers .