RICHI MACHINERY PRODUCTS

High quality and efficient pellet production equipment ensures high output, smooth and safe pellet production of animal feed production lines, fish feed pellet production line, wood pellet mill, or biomass pellet plants.

RICHI Machinery Pellet Equipment

Henan RICHI Machiney Co., Ltd. is a manufacturer and supplier of feed machinery and biomass pellet production equipment for customers. The main mechanical equipment products include animal feed pellet making machine, wood pellet machines, biomass pellet machine, floating fish feed extruder machine, and auxiliary equipment such as hammer mill, mixer and packing machine on pellet production line.

RICHI Machinery products has high quality materials, brand accessories, humanized design and advanced manufacturing technology. As the core of the feed pellet production plant or biomass pellet production line, mechanical equipment directly determines its production efficiency. Therefore, we have been providing customers with quality pellet equipment.

Can’t find a reliable pellet equipment manufacturer?

Contact us for quality pellet equipment

Hot-Sale Products

—— RICHI MACHINERY ——

You can choose according your raw materials, final pellet types and size, capacity. Of course, we can also customize the machine according to the customer’s needs.

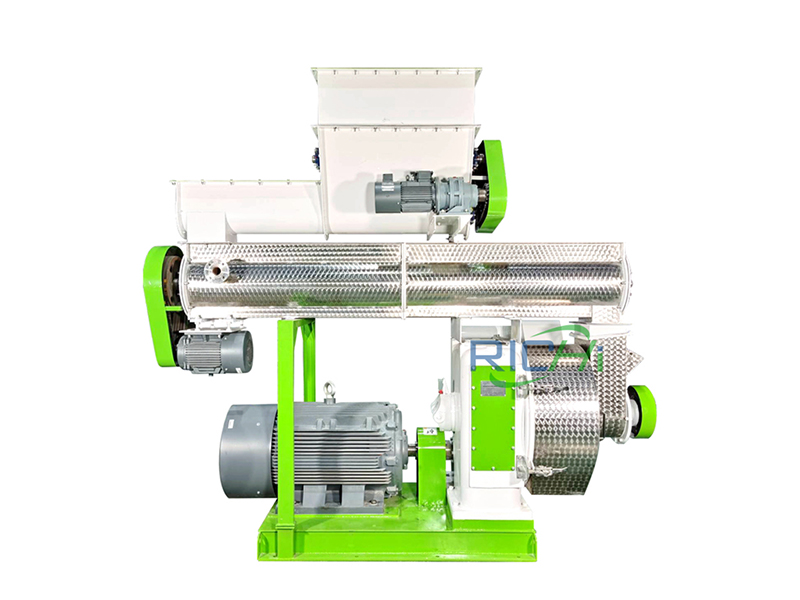

Animal Feed Pellet Making Machine

Capacity: 1-45T/H

Suitable for 2-18mm poultry, livestock or aquatic feed pellet production.

Capacity: 0.7-40T/H

Suitable for granulation containing grass and grain raw materials.

Wood Pellet Machine

Capacity: 0.3-5T/H

Suitable for granulation of sawdust, straw and other biomass raw materials.

Capacity: 2-14T/H

Suitable for the production of floating fish feed, pet food pellet.

FAQ: What are the raw materials of RICHI pellet machine?

Corn flour, wheat flour, soybean flour and other raw grains; Alfalfa and other forages; Sawdust, straw, fruit hulls and other agricultural and forestry residues; Premix; Organic fertilizer; Tire fibers, etc.

1-45T/H Animal Feed Pellet Making Machine

RICHI SZLH animal feed pellet making machine is suitable for the production of 2-18mm feed pellets of poultry and livestock, and the raw materials are mainly corn flour, wheat flour and other raw grains. If the feed containing grass is processed, the pellet machine is equipped with a forced-feeder and an anti-arching feeder.

Poultry Feed Pellet Machine Price

- Price: $7,000-$100,000

- Capacity: 1-45T/H

Chicken Feed Making Machine Price

- Price: $7,000-$100,000

- Capacity: 1-45T/H

Pig Feed Pellet Machine

- Price: $7,000-$100,000

- Capacity: 1-45T/H

RICHI SZLH Animal Feed Pellet Machine Parameters

| Model | Capacity(T/H) | Main Motor Power(kw) | Feeder Power(kw) | Conditioner Power(kw) | Finished Pellet Diameter(mm) |

|---|---|---|---|---|---|

| SZLH250 | 1-2 | 22 | 1.1 | 1.5 | 2-12 |

| SZLH320 | 3-4 | 37 | 1.5 | 2.2 | 2-12 |

| SZLH350 | 5-7 | 55 | 1.5 | 3 | 2-12 |

| SZLH420 | 8-12 | 110 | 1.5 | 7.5 | 2-12 |

| SZLH508 | 10-18 | 160 | 2.2 | 11 | 2-12 |

| SZLH558 | 15-25 | 180/200 | 2.2 | 11 | 2-12 |

| SZLH678 | 20-30 | 220/250 | 2.2 | 11 | 2-12 |

| SZLH768 | 25-40 | 250-280 | 2.2 | 11 | 2-12 |

| SZLH858 | 28-45 | 315/355 | 2.2 | 15 | 2-18 |

Cattle Feed Pellet Machine

- Price: $7,000-$100,000

- Capacity: 0.7-40T/H

Goat Feed Pellet Making Machine

- Price: $7,000-$100,000

- Capacity: 0.7-40T/H

Rabbit Feed Pellet Machine

- Price: $7,000-$100,000

- Capacity: 0.7-40T/H

RICHI SZLH Grass Pellet Machine for Containing Grass Feed Pellet

| Model | Capacity(T/H) | Main Motor Power(kw) | Feeder Power(kw) | Conditioner Power(kw) | Finished Pellet Diameter(mm) |

|---|---|---|---|---|---|

| SZLH320 | 0.7-4 | 22 | 1.1 | 2.2 | 2-12 |

| SZLH350 | 1-6 | 37 | 1.5 | 4 | 2-12 |

| SZLH420 | 2-10 | 90 | 1.5 | 7.5 | 2-12 |

| SZLH520 | 3-15 | 132 | 1.5 | 7.5 | 2-12 |

| SZLH768 | 4-30 | 250 | 2.2 | 11 | 2-12 |

| SZLH858 | 5-40 | 280 | 3 | 15 | 2-12 |

FAQ: What is the difference between chicken feed pellet machine and cattle feed pellet machine?

Chicken feed pellet machine is one of the most common feed pellet machine, used for the processing of grain raw materials, the production of feed pellets are mainly used to feed chickens, ducks, geese, pigs and other poultry and livestock. Cattle feed pellet machine is also known as grass pellet machine, mainly used for the processing of grass-containing animal feed, can also be used for pure grain feed processing. The feed pellets produced can be used to feed cattle, sheep, horses, camels, rabbits, etc. You can choose according to the type of animal feed produced.

Compared with the chicken feed pellet machine, the cattle feed pellet machine adds a forced feeder and anti-arching feeding device, which are set for the relatively light characteristics of the grass, which helps to form the grass-containing feed pellets. In addition, the proportion of grass in the raw material will also affect the output of feed pellets, the specific situation can inquire us.

Fish Feed Making Machine

Suitable for the production of aquatic animal feed pellets. The fish feed pellets have comprehensive nutrition, strong stability in water, and are more conducive to the growth and development of fish and shrimp.

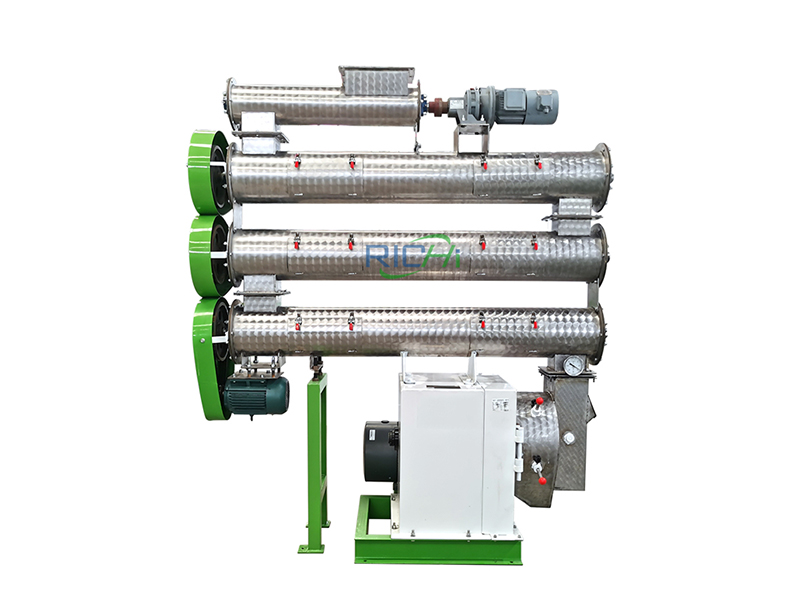

1-45T/H Fish Feed Pellet Machine

RICHI SZLH feed pellet machine with 2-layers conditioner

0.3-15T/H Shrimp Feed Making Machine

RICHI SZLH feed pellet machine with 3-layers conditioner

1-3mm Shrimp Feed Pellet Machine

RICHI SZLH feed pellet machine with 3-layers conditioner

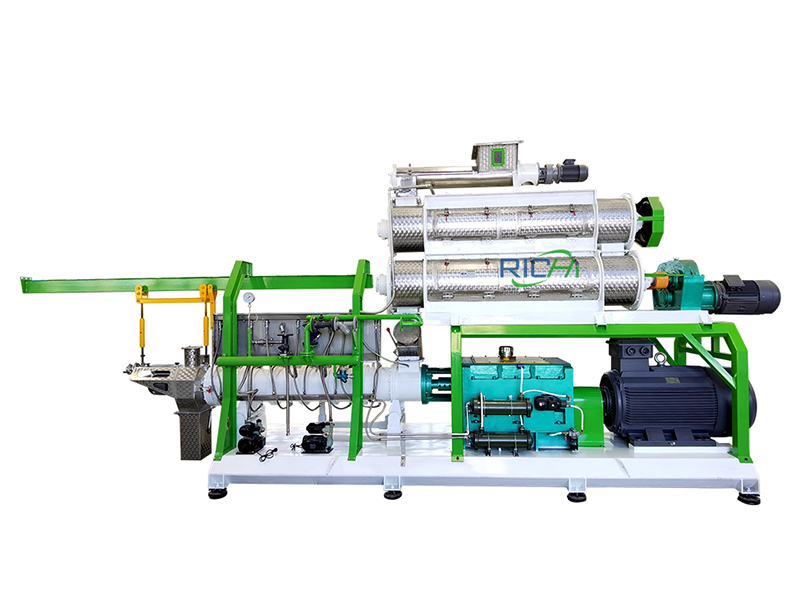

High-Grade Fish Feed Pellet Extruder

1.5-12T/H RCPH series twin screw extruder for floating fish feed or pet food

3-14T/H Floating Fish Feed Extruder Machine

SPHS series aquatic single screw extruder

1.5-12T/H Floating Fish Feed Machine

RCPH series twin screw extruder for floating fish feed or pet food

FAQ: How to choose a fish feed making machine?

Fish feed is divided into sinking feed and floating feed. The production of floating fish feed pellets usually selects fish feed extruder. The production of sinking feed pellets selects a pellet machine, of which fish feed usually selects a pellet machine with a 2-layer conditioner, and shrimp feed chooses a pellet machine with a 3-layer conditioner. You can contact us for more useful information.

Biomass Pellet Making Machine

From biomass raw materials to 6-12mm biomass pellet fuel. Its raw materials come from a wide range of sources, including wood sawdust, straw, rice husks, coconut husks and other agricultural wastes.

0.3-5T/H Wood Pellet Making Machine

RICHI MZLH series wood pellet machine for 6-12mm wood pellets

6-12mm Biomass Pellet Machine Price

RICHI MZLH series biomass pellet machine capacity: 0.3-5T/H

1-12T/H Organic Fertilizer Pellet Machine

Suitable for animal manure or food residue pellets production.

Alfalfa Pellet Machine For Sale

Suitable for processing alfalfa into alfalfa feed or fuel pellets.

Straw Pellet Machine

Suitable for straw,grass and other biomass pellet production line.

Hemp Pellet Machine

Customers can customize according to their own raw materials.

Hay Pellet Machine

With a forced-feeder and conditioner for hay or other light materials pelletizing.

Rice Husk Pellet Machine

The capacity of 0.3-5T/H can be customized according to your needs.

Wood Chip Pellet Machine

Suitable for the pelletizing system of wood pellet production.

chicken manure pelletizer

Processing chicken manure into chicken manure pellets, suitable for chicken farms and organic fertilizer plants.

cow dung pellet machine

Processing cow dung into cow dung pellets, suitable for cow farms, organic fertilizer plants and biomass fuel plants.

cat Litter Pellet machine

Processing cat litter pellets, suitable for cat llitter production line and cat litter factory.

RICHI MZLH Biomass Pellet Machine Parameters

| Model | Capacity for Wood, Sawdust,Straw, Husk, etc.(T/H) | Capacity for Organic Fertilizer(T/H) | Main Motor Power(kw) | Main Motor Series | Ring Die Diameter(mm) | Finished Pellet Diameter(mm) |

|---|---|---|---|---|---|---|

| MZLH320 | 0.3-0.5 | 1-2 | 22 | 6/8P | 320 | 6-12 |

| MZLH350 | 0.5-0.7 | 3-4 | 37 | 6/8P | 350 | 6-12 |

| MZLH420 | 0.8-1.5 | 5-6 | 90 | 6/8P | 420 | 6-12 |

| MZLH520 | 2-2.5 | 7-8 | 132 | 6/8P | 520 | 6-12 |

| MZLH768 | 2.5-4 | 9-10 | 250 | 6/8P | 768 | 6-12 |

| MZLH858 | 4-5 | 10-12 | 280 | 6/8P | 858 | 6-12 |

FAQ: Why use RICHI biomass pellet machine to produce biomass pellet?

Biomass pellet machine is an environmental protection equipment that can process biomass raw materials into combustible biomass pellets. Biomass pellets are cleaner and burn with less harmful gases. And biomass pellets have the advantages of convenient storage and transportation. RICHI’s biomass pellet machine has higher quality, larger output, more user-friendly use and longer life.

Auxiliary Equipment

The production process from raw materials to final pellets also requires other equipment to assist, and the following are some common auxiliary equipment.

Feed Hammer Mill

Water-drop hammer mill. Suitable for crushing grain raw materials.

Drum Wood Chipper

Suitable for the treatment of logs, cutting wood blocks into small pieces.

Grass Crusher

Suitable for straw, hay, grass and other light materials crushing.

Sawdust Dryer

RICHI rotary drum dryer for sawdust, grass powder or other biomass powder drying.

Animal Feed Mixing Machine

RICHI SLHJ series single shaft double layer paddle mixer with higher mixing uniformity and efficiency.

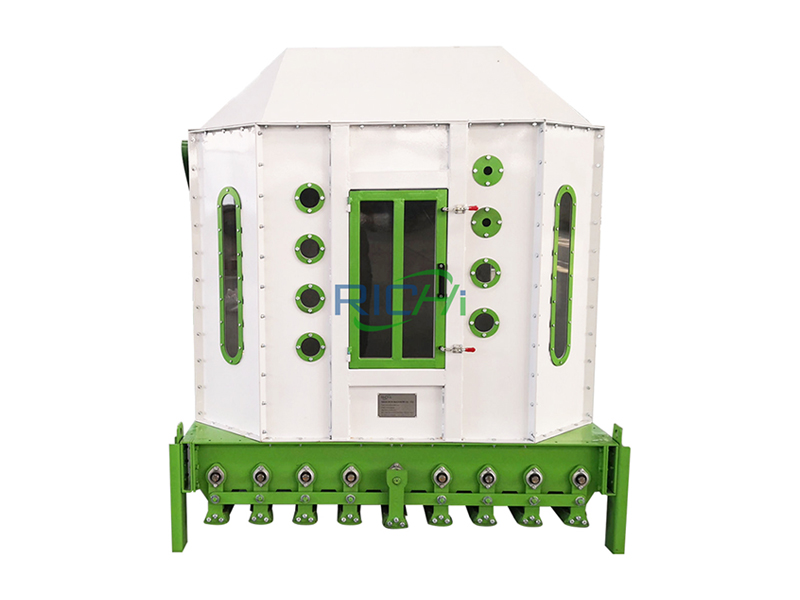

Feed Pellet Cooler

SKLN series counterflow cooler for cooling formed pellets.

FAQ: What is the role of auxiliary equipment in setting up a complete pellet production line?

The main equipment of pellet production line is pellet machine, and the role of pellet machine is to press the raw materials after grinding into pellets. However, our raw materials are often not powdered substances that can be directly used for processing, and the pellets that come out of the pellet machine also need to be cooled and packaged. Therefore, we need auxiliary equipment to build a complete pellet production line. In this way, the production of from raw materials to final pellet products can be achieved.

Advantages of RICHI Pellet Equipment

Quality Machine Selection

Each of our machines has been carefully selected, and the motors and accessories are also from international famous brands. The feedback from customers is also very good, the wear rate and maintenance rate are very low in the industry, so regular customers will choose us when upgrading and building new production lines. The parts of feed machinery and equipment in contact with feed are made of stainless steel. Forging process, Siemens motors, SKF bearings, etc. You can inquire about the details of each equipment and consult us.

Reasonable Mechanical Design and Customizable

Reasonable design not only improves production efficiency, but also has more humanization, making the use of the machine more convenient, simple and safe. These are often in the details, but they are crucial. Such as ring mold replacement design, equipment inspection door, working room observation hole, magnet installation design for permanent magnet drum. What’s more, our products can be customized according to customer needs.

Advanced Technological Equipment

RICHI Machinery has always attached great importance to research and development and production, and has also paid practical actions. Not only attaches importance to the training of outstanding scientific research personnel, but also invests the international leading process equipment in the factory, including large numerical control cutting machine, numerical control drilling machine, automatic arc-submerging welder, dynamic balance detector, sand blasting rust and paint production line. These ensure that the quality of our equipment is the best in the industry, and also ensure the successful completion of customers’ projects.

Strict Production Control

We have standardized production workshops with advanced process equipment, which can meet the production needs of products with different design schemes. The precise and intensive inspection process ensures that the performance of the machine meets the target. We will keep in touch with customers in the process of equipment production, , realizing workers, designers, technicians, sales and customers at the same time as supervisors, to ensure the quality of the machine and production progress.

Cases Related to Our Pellet Equipment Products

500+ /EQUIPMENT MODELS

Our wide range of equipment models can meet the individual needs of different customers. Each customer can choose the machine that best suits them to meet their own pellet production requirements.

127+ /countries and regions

RICHI’s pellet equipment has been sold to the world with the construction of pellet production lines, and the reason why these production lines can operate well is closely related to good equipment quality.

SZLH420 Shrimp Feed Pellet Machine and RCPH120*2 Twin Screw Extruder In Iran

1-2T/H floating fish feed pellet and shrimp feed pellet production line

Total project price: $300,000-400,000. On April 19, 2022, we commissioned an aquatic feed line for a customer in Iran, the line is used for the production of 1-2T/H floating fish feed and shrimp feed pellets. Among them, 60 days for the completion of mechanical equipment production, 40 days for shipping, and 90 days for project installation.

The main equipment of the pelletizing section is RICHI SZLH420 feed pellet machine with 3-layers stainless steel conditioner and RCPH120*2 Twin screw extruder. Auxiliary equipment on the production line are SCY63 drum type precleaner, SFSP66*60 hammer mill, DHG-2000Q drying machine, JBS-50 customized conveyor, TDZS80 vibrating screener, etc. Our equipment has been strictly tested during and after production, and will also be tested after customer installation to ensure the normal operation of the production line.

RICHI SZLH250 Chicken Feed Pellet Machine in Tanzania

1-2T/H chicken feed pellet production line

The project started on July 11, 2019, and we sent two installation engineers to assist in the installation of the 1-2T/H chicken feed pellet production line for the customer in Tanzania, which was completed in 10 days. Total power of the line is 47.95KW. We are equipped with RICHI SZLH250 chicken feed pellet machine, as well as auxiliary equipment including screw conveyor, hammer mill, mixer and cooling belt. Customer feedback this is a very cost-effective production line, they are very satisfied with the quality of our machines and the solution design.

SZLH320 Grass Pellet Machine with Forced Feeder in UZ

1-2T/H containing 50%-80% grass animal feed pellet production line

On December 3, 2021, we established an animal feed production line for our customers in Uzbekistan. The total price of the project is no more than $100,000. The production cycle of the equipment is 30 days, the land transport is 20 days, and the installation is 15 days. The customer’s raw materials are 50%-80% grass and grain, and the output demand is 1-2T/H. So, we chose the SZLH320 grass Pellet machine with a forced feeder for our customers, which solves the difficult problem of granulation of grass-containing feed. Auxiliary equipment are 9FB56*40 grass crusher, HZG0.8*8 drum dryer, SLHY.2.5L mixer, DCS-50 packaging machine, SKLN11*11 cooling machine, U-screw conveyor, PDS-50 rolling conveyor and so on. In the end, the customer was very satisfied with the molding rate and yield of the pellets.

MZLH520 Wood Pellet Machine in Canada

2-3t/h full automatic wood pellet production line

The customer wants to process 50% moisture wood chips and 50% moisture sawdust into 6-12mm wood pellets. Therefore, the customer came to us and trusted our equipment quality and production process, hoping that we could give a suitable solution. So, on August 1, 2018, we established a 2-3t/h full automatic wood pellet production line for this Canadian customer. The pelletizing equipment is RICHI MZLH520 wood pellet machine, auxiliary equipment include wood crusher, shifter, dryer, storage bin, cooler, shifter, auto-packing.