Organic fertilizer pellet machine

Organic fertilizer pellet machine is an equipment for processing fermented animal waste, organic waste, etc. into efficient organic fertilizer pellets. RICHI organic fertilizer pellet making machine is a high-yield ring die pellet machine, which has been widely used in animal husbandry manure treatment, biomass decay processing and commercial organic fertilizer granulation.

Brief of RICHI organic fertilizer pellet machine

The organic fertilizer granulator machine has smooth production, stable operation, uniform pellet production, moderate hardness, and is an ideal organic fertilizer granulator machine.

- Capacity: 1-12T/H

- Main power: 22-280kw

- Produced organic fertilizer pellet diameter: 6-12mm

- Features: Customizable

- Applicable raw materials: chicken manure, cow dung, sheep manure, horse manure and other animal waste; Residues of straw crops; Food scraps, etc.

- Use of organic fertilizer pellets: crop fertilization, vegetable fertilization, flower fertilization, etc.

- Main function of organic fertilizer pellets: improve soil environment and promote plant growth

This video is the trial video of RICHI organic fertilizer pellet making machine. We can see that the organic fertilizer after fermentation and crushing is artificially sent into the side opening, and after the processing of the pellet machine, the finished organic fertilizer pellets are discharged from the outlet. In the actual production, the organic fertilizer pellet mill is the main equipment of the production line and the core machine of the pelletizing section, which is usually connected with the conveying equipment and auxiliary equipment such as the screw conveyor to achieve automatic pelletizing.

We can provide customers with fertilizer pelletizer machine, organic fertilizer production line and equipment, organic fertilizer production solutions and so on. Contact us to get your own organic fertilizer pellet machine.

Structure and characteristics of RICHI organic fertilizer pellet machine

The structure of the RICHI fertilizer pelletizer machine is similar to that of the wood pellet machine, which mainly includes a feeder, a granulation chamber, a main motor and a transmission device.

Stainless steel feeder

The feeder of the organic fertilizer granulator machine is made of stainless steel and SKF bearing, which improves its wear resistance and service life. Feeders are usually equipped with anti-arching devices to prevent the arching of organic fertilizer materials containing certain moisture after fermentation. An observation hole is cut on the side of the feeder so that the pelletizing worker can observe the material in the feeder.

granulation chamber

The pelleting chamber is the core part of organic fertilizer pelleting, including the material plate, the press roller, the stainless steel ring die and the cutter. The organic fertilizer pellet making machine is equipped with a forced feeding device outside the granulation chamber, which can help the organic fertilizer enter the working part of the pelleting room faster and improve the production efficiency of the pellet machine. This is similar to wood chips and grass pellet machines.

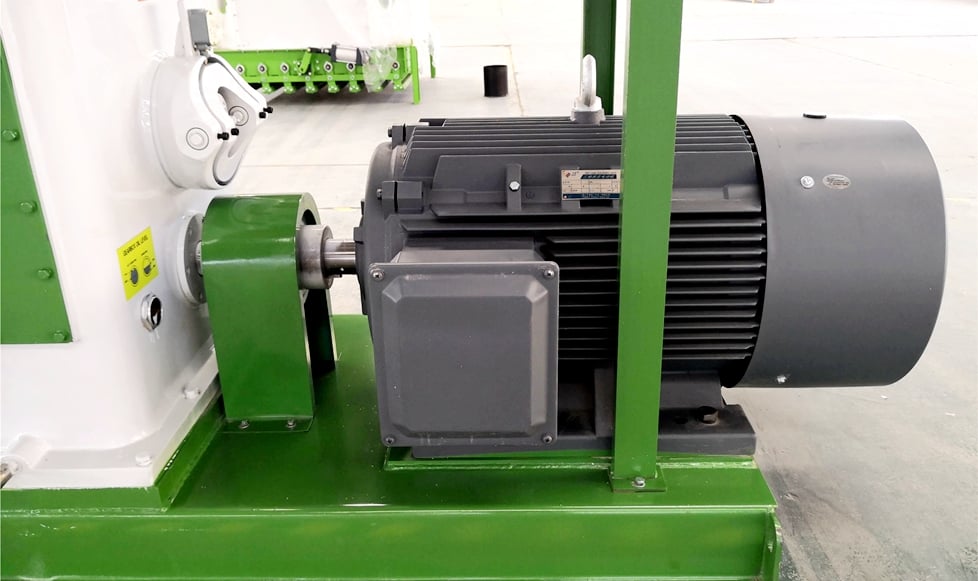

Siemens motor

The main motor adopts Siemens motor to ensure its quality. In addition, the higher the series of the motor, the greater the torque, the slower the speed, the greater the force. In order to facilitate the production of organic fertilizer, the main motor series adopts 6P or 8P. Therefore, you can rest assured to buy RICHI organic fertilizer pellet mill, its granulation effect has been repeatedly tested.

gear drive

The transmission device consists of a gear box, a coupling and a motor. The main transmission adopts gear transmission mode, which has high precision, high efficiency and low maintenance rate. Inside the gearbox are gears, tooth shafts, main shaft and empty shaft, all of which are made of 42CrMo material with high wear resistance. Using the international advanced level of coupling, the whole machine structure layout is reasonable, small volume.

More Display Advantages

In addition to the above parts, the RICHI fertilizer pelletizer machine has many details to improve its performance, quality and humanization, such as the safety pin to protect the machine from overload, durable stainless steel door cover and so on.

Models and parameters of RICHI organic fertilizer pellet machine

According to the common production of customers, RICHI has launched 6 organic fertilizer pellet machine models. In addition, RICHI can also customize other production machines, in which the ring die, motor, feeder and other components can be customized.

MZLH320 organic fertilizer pellet machine

- Capacity:1-2T/H

- Main motor power:22KW

- Main motor series: 6/8P

- Ring die diameter: 320mm

- Final pellet size: 6-12mm

MZLH350 organic fertilizer pellet making machine

- Capacity:3-4T/H

- Main motor power:37kw

- Main motor series: 6/8P

- Ring die diameter: 350mm

- Final pellet size: 6-12mm

MZLH420 organic fertilizer pellet mill

- Capacity:5-6T/H

- Main motor power:90kw

- Main motor series: 6/8P

- Ring die diameter: 420mm

- Final pellet size: 6-12mm

MZLH520 compost pellet making machine

- Capacity:7-8T/H

- Main motor power:132kw

- Main motor series: 6/8P

- Ring die diameter: 520mm

- Final pellet size: 6-12mm

MZLH768 cow manure fertilizer pellet machine

- Capacity:9-10T/H

- Main motor power:250kw

- Main motor series: 6/8P

- Ring die diameter: 768mm

- Final pellet size: 6-12mm

MZLH858 chicken manure pellet machine

- Capacity:10-12T/H

- Main motor power:280kw

- Main motor series: 6/8P

- Ring die diameter: 858mm

- Final pellet size: 6-12mm

The parameters may be slightly adjusted according to the actual situation, and the actual reply shall prevail.

Applications of organic fertilizer pellet machine

Organic fertilizer pellet machine can not only be used in organic fertilizer production plants, but also for biomass pellet plants, ruminant feed plants, and can also be used for pelleting in chemical, pharmaceutical and other industries.

Organic fertilizer production plant

organic fertilizer pellet making machine is specially manufactured for the production of organic fertilizer pellets, which is the main and commonly used equipment of organic fertilizer pellet plant. Any factory that wants to process organic fertilizer into pellets needs to configure an or more fertilizer pelletizer machine. For organic fertilizer plants, it is very important to select a high-yield and efficient pellet machine.

Biomass pellet plant

The raw material of organic fertilizer pellet mill is also biomass, so its structure and working principle are almost the same as that of biomass pellet machine. Many biomass pellet plants, including wood pellet plants, straw pellet plants, and cat litter pellet plants can use organic fertilizer pellet machines for granulation. If there is a special need, just make adjustments on the parts.

Ruminant feed plant

Because of the characteristics of cattle, sheep, horses, camels, rabbits and other ruminant animals eating grass, ruminant feed plants will carry out grass pellet pelleting to meet the needs of these animals for grass feed. The granulator used in the grass pelleting section can use an organic fertilizer granulator, equipped with a conditioner if necessary.

Why use organic fertilizer pellet machine to produce organic fertilizer pellet?

The raw materials of organic fertilizer are usually livestock manure, agricultural waste, peat, household waste, etc. These raw materials come from a wide range of sources and are cheap, but when organic fertilizer pellets are produced, waste will be turned into treasure, creating value and income for sellers and buyers.

In addition, these raw materials are not effectively treated, will pile up, causing pollution and burden on the living environment. Processing into organic fertilizer pellets can be reasonable storage and secondary use.

Organic fertilizer pellets contain nitrogen, phosphorus, potassium, microorganisms, enzymes and other components, which can improve the quality of soil, increase soil fertility, promote the growth of plants, and improve the yield of fruits.

Compared with organic fertilizer powder, organic fertilizer pellets are more convenient for transportation and storage, and are also suitable for large-scale mechanical seeding. Fertilization is more uniform and not easily dispersed by the wind.

An investment in RICHI fertilizer pelletizer machine can produce and operate for several years. With the increasing application of organic fertilizer pellets, it can bring good returns to investors.

Organic fertilizer pellet production process and equipment

The production process of organic fertilizer pellets includes dehydration & fermentation, crushing, drying, granulation, cooling, screening, packaging, etc. The production process of organic fertilizer pellets can be changed and needs to be analyzed according to the specific situation. Contact us to customize organic fertilizer pellet production line.

Dehydration and fermentation process

Dehydration and fermentation are the necessary steps for organic fertilizer granulation and one of the main differences from other biomass or feed granulation. The fermentation process can improve its fertility, but also effectively kill harmful bacteria and eggs. The stack-turning machine is used for dynamic composting, allowing fermentation to input oxygen while avoiding harmful gases and explosions.

Main equipment

stack-turning machine

Grinding technology

The organic fertilizer after fermentation is crushed into powder, powder organic fertilizer can be used directly, or can be granulated and then used, at this time to see their own needs.

Main equipment

organic fertilizer crusher

Drying process

Organic fertilizer usually has a large water content, and can be dried in a dryer before granulation. RICHI Machinery has horizontal rotary dryer, can effectively dry the organic fertilizer powder.

Main equipment

organic fertilizer dryer

Granulation process

On the production line, the organic fertilizer is transported to the feeder of the organic fertilizer pellet machine through the conveyor device, and then into the chute. The gaps between the press rollers and the ring die are entered under the action of a forced feeder, a plate and gravity. The pellets are extruded from the die hole under the action of pressure, and the cutter cuts them into pellets.

Main equipment

organic fertilizer granulator machine

Cooling section

The cooling section, like the biomass pellet production line and feed pellet production line, is used to cool the pellets after pelleting. The organic fertilizer pellets coming out of the granulator have high temperatures and need to be cooled to room temperature in a short time to ensure particle quality and storability.

Main equipment

pellet cooling machine

Packing section

The pellet packing machine is used for the packaging of finished organic fertilizer pellets, and the packaging section is equipped with the production line of organic fertilizer pellets and the organic fertilizer plant. The current RIHCI automatic packing machine can be used to weigh, bag and seal pellets. Automated packing machines can save manpower, especially suitable for large production lines.

Main equipment

pellet packing machine

Global cases of RICHI organic fertilizer pellet machine

With high-quality machines, reasonable prices, perfect service and rich experience, RICHI has won the trust of customers and completed more and more organic fertilizer pellet plant projects around the world.

MZLH320 organic fertilizer granulator machine in Germany

- Sale date: May 21, 2024

- Guide price: 20,000 to 30,000 EUR

- Customer’s main raw materials: poultry manure

MZLH520 organic fertilizer pellet mill in Thailand

- Sale date: June 25, 2024

- Guide price: $40,000 – $50,000

- Customer raw material features: 20%-30% water content

3-4T/H organic fertilizer pellet production line

- Country: Pakistan

- Sale date: August 15, 2023

- Customer raw materials: foliar fertilizer

8T/H organic waste production line

- Country: Canada

- Customer raw materials: urban residents organic waste

- Guide Price: inquiry

500+

500+ device models

1000+

1000+ turnkey projects

127+

127+ countries and regions

2000+

2000+ customers

Frequently Ask Question

Frequently Ask Question

Click Here to buy now.

What do you need to pay attention to in the production of organic fertilizer?

The raw materials of organic fertilizer pellets are special, and special attention should be paid to environmental protection issues and product safety issues in the production process. If the water, oxygen and carbon nitrogen ratio in the fermentation process is inappropriate, it will cause the production of harmful gases or microorganisms, which will cause pollution. Organic fertilizer plants need to control the water content of organic fertilizer, carbon nitrogen ratio and fermentation temperature, and the stack-turning machine also plays a certain role in supplying oxygen.

How to choose organic fertilizer pellet machine manufacturer?

There are many manufacturers of organic fertilizer pellet machine, and we need to find a reliable and regular manufacturer. Because organic fertilizer machinery is also a medium and large machinery, once it is put into use for a long time. We must choose safe, stable, durable machines, and good after-sales service manufacturers.

We recommend a professional pellet equipment manufacturer in China – Henan RICHI Machinery Co., LTD., the company has two machinery manufacturing plants in Henan, China, and passed the BV factory inspection, all products have passed the ISO, CE and other international certification. Founded in 1995, RICHI Machinery has been engaged in the pellet equipment industry for nearly 30 years, and has completed more than 2,000 projects worldwide. All products of RICHI Machinery have their own original accessories to ensure efficient operation of machinery and low maintenance rate. RICHI Machinery to provide customers with one-stop service, from the inquiry, the program and equipment, to the installation and commissioning and operation training, we have a complete one-stop service. Choose RICHI, your organic fertilizer pellet plant upgrade or construction can be worry-free.

Any Question?

You can ask anything you want to know about Feedback

RICHI MACHINERY

4R SERVICE

Worry-Free All the Way

Reliability

We are committed to providing reliable equipment and services. You can fully rely on RICHI Machinery to ensure the stability and efficiency of your production process.

Responsivene

We promise to maintain a rigorous attitude throughout our entire business. Strive for excellence and meticulousness are the most basic concepts we follow.

Rigorousness

We promise to respond quickly when you need us. No matter what challenge or need you face, our team will provide you with a solution at an efficient pace to ensure your business always runs smoothly.

Reassurance

We promise to provide one-stop service so that you have no worries throughout the process. RICHI Machinery will provide you with full reassurance.