Grass pellet machine

RICHI grass pellet machine can produce cattle, goat, rabbit and other ruminant feed pellets, and also grass, straw, husk and other biomass pellet fuels. So, our grass pellet mills are very popular in the animal feed pellet production line and biomass pellet plants.

RICHI MACHINERY

RICHI SZLH grass pellet machine for sale

RICHI SZLH series grass pellet machine can process pure grass powder raw materials, also can process the mixture of grass powder and powdered grain.

- Capacity: 0.7-40T/H

- Guide price: 7,000-100,000 US Dollars

- Pellet diameter: 6-12mm

- Main power: 22-280kw

- Raw Materials: alfalfa, hay, lucerne, straw, husk, hemp and other grasses; corn, wheat, soybean and other grains; premix, additive,etc.

- Applicable animals: cattle, cow, sheep, goat, rabbit, horse, camel and other ruminants.

- Features: RICHI grass pelletizers are equiped with arch-caking feeder, conditioner and forced feeder.

- Applications:livestock feed pellet mill, cattle feed plant machine, biomass pellet plant, etc.

- Note: RICHI can customize grass pelletizer to meet customer’s conditions and needs, such as types of raw materials, budget, capacity, size of grass pellets, local power conditions, etc.

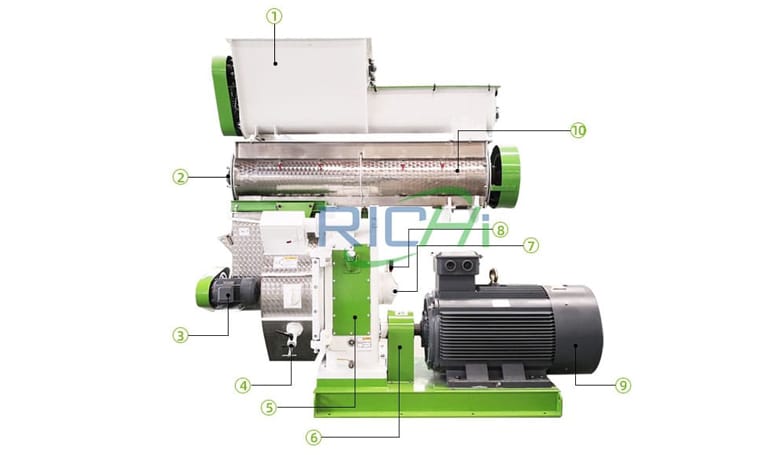

Basic Structure of RICHI SZLH Grass Pellet Machine

- Stainless steel, arch-caking, feeder

- SKF bearing

- Forced feeder with worm gear reducer

- Cutter assembly

- Gearbox

- Shaft coupling: Compensation serpentine spring coupling with international advanced level

- Safety assembly

- Limit switch: When the machine is overloaded or faulty, the power supply can be automatically cut off to protect the pellet machine.

- Siemens motor

- Stainless steel conditioner

Why uses RICHI SZLH grass pellet machine to produce grass pellets?

RICHI grass pellet machine combines the advantages of biomass pellet machine and animal feed pelletizer. It is not only suitable for the pelleting of small density powdery materials, but also can meet the requirements of animal feed curing and sterilization.

Stainless steel conditioner

Stainless steel conditioners are commonly found in RICHI Machinery’s animal feed pellet machines, which are used to mature, gelatinize and sterilize materials. In this way, the feed pellets produced are more conducive to the absorption and health of animals. The stainless steel conditioner in the hay pellet machine has the function of softening the grass powder, making the grass powder easier to granulate and improve the capacity. Therefore, RICHI’s customers usually choose a grass pellet machine with a conditioner.

Stainless steel ring die

The ring die is made of stainless steel, and the opening rate reaches 100%, which improves the quality and yield of grass pellets. Then, the diameter of the die holes and the compression ratio of the ring die can be customized, and the customer can decide the size and hardness of the grass pellets. Besides, RICHI grass pellet machine is equipped with a lifting device, users can easily change the ring die. We usually provide customers with multiple ring dies and corresponding rollers, so they can replace at any time.

Arch-caking and stainless steel feeder

Feeder of RICHI grass pellet mill is specially designed for grass powders and wood chips including lucerne, alfalfa, hay,corn straw, rice husk, sawdust, fiber and so on.Because of the grass powders are light and they are easy to arch, the feeder adopts bigger opener, larger volume, arch-caking device.This can help grass power entry grass pellet machine smoothly and evenly.In addition, stainless steel is more durable and can prevent material contamination.

Forced feeder

Forced feeder adopts worm gear reducer, which is one of the features of all RICHI biomass pellet machines. For materials that do not flow easily, the forced feeder acts as a boost when they enter the pelletizing chamber. The forced feeder is suitable for wood chips, grass poeder, straw, rice husk, hemp, hops, alfalfa, hay, tire fiber, organic fertilizer and other pellet machines.

For more details, please contact us.

Types of RICHI SZLH Grass pellet machine

SZLH320 grass pellet machine for sale

- Capacity: 0.7-4T/H

- Main power: 22kw

- Finished pellet diameter: 6-12mm

SZLH350 hay pellet machine for sale

- Capacity: 1-6T/H

- Main power: 37kw

- Finished pellet diameter: 6-12mm

SZLH420 alfalfa pelletizer machine

- Capacity: 2-10T/H

- Main power: 90kw

- Finished pellet diameter: 6-12mm

SZLH520 cattle feed pellet machine

- Capacity: 3-15T/H

- Main power: 132kw

- Finished pellet diameter: 6-12mm

SZLH768 rabbit feed pellet making machine

- Capacity: 4-30T/H

- Main power: 250kw

- Finished pellet diameter: 6-12mm

SZLH858 goat feed pellet mill

- Capacity: 5-40T/H

- Main power: 280kw

- Finished pellet diameter: 6-12mm

grass pelletizer

- Capacity: 0.7-40T/H

- Main power: 22-280kw

- Finished pellet diameter: 2-12mm

husk pellet machine

- Capacity: 0.7-40T/H

- Main power: 22-280kw

- Finished pellet diameter: 2-12mm

lucerne pellet machine for sale

- Capacity: 0.7-40T/H

- Main power: 22-280kw

- Finished pellet diameter: 2-12mm

Parameter table of RICHI SZLH series grass pellet machine

| Model | Capacity(T/H) | Main Motor Power(kw) | Feeder Power(kw) | Conditioner Power(kw) | Finished Pellet Diameter(mm) |

| SZLH320 | 0.7-4 | 22 | 1.1 | 2.2 | 2-12 |

| SZLH350 | 1-6 | 37 | 1.5 | 4 | 2-12 |

| SZLH420 | 2-10 | 90 | 1.5 | 7.5 | 2-12 |

| SZLH520 | 3-15 | 132 | 1.5 | 7.5 | 2-12 |

| SZLH768 | 4-30 | 250 | 2.2 | 11 | 2-12 |

| SZLH858 | 5-40 | 280 | 3 | 15 | 2-12 |

1. The lower the proportion of grass powder in the raw materials, the higher the proportion of grains, the higher the output of grass pellet mill.

2. Pure grass pellets are usually 6-12mm in diameter and can be used as ruminant feed or pellet fuel.

3. The larger the final pellet diameter, the higher the output of the grass pellet machine.

Global Case

3-5T/H grass pellet machine for ruminant feed pellets

The RICHI grass pellet machine can process the crushed grass, crop straw, grain and other raw materials into grass pellets. These pellets can be used as complete pellet feed for ruminants. So, the Indonesian customer chose the RICHI SZLH grass pellet mill for production of ruminant feed pellets.

- Project full name: 3-5T/H ruminant feed pellet production line in Indonesia

- Country: Indonesia

- Project Start Date: April 9, 2018

- Capacity: 3-5T/H

- Customer’s raw materials: alfalfa, straw, husk, corn, soybean meal

- Customer’s pellet diameter: 6-12mm

- The production line size: 10m*5m*12m

- Total project power: about 200kw

- Number of workers required for the production line: 4

We provide customers with production line layout drawings, steel structure installation drawings, equipment installation drawings and other information. The installation period of this project is 30 days, and RICHI’s 2 engineers specially went to Indonesia to assist the customer.

Note: Different growth stages of cattle and sheep feed pellet formulations are not the same, the customer needs to adjust the proportion of raw materials. At the same time, the capacity of the production line is not the same.

Main process and equipment of ruminant feed pellets production

Crushing of alfalfa, straw and husk

Main equipment: grass hammer mill

Crushing alfalfa, straw and husk raw materials into 3-5mm grass powder. RICHI grass hammer mill is equiped with forced feeding device, it is conducive to the crushing of customers’ alfalfa grass, straw and other light materials.

Drying of grass powder

Main equipment: sawdust dryer

Drying wet grass powder into 15% water content. The sawdust dryer is rotary drum drying machine, suitable for drying 3-5mm wood chips, grass powder, straw, husk, etc.

Crushing of corn and soybean meal

Main equipment: grain hammer mill

Grain hammer mill usually adopts RICHI SFSP hammer mill, the crushing efficient in raw grains is higher. When the proportion of grains is small, they can also be spread on straws and crushed together with straw.

Mixing of grass and grain powder

Main equipment: Hay mixer for sale

Type: SLHY single shaft double ribbon mixer. The effective volume of the mixer is relatively high, and the mixing form is continuous turning and convection. Therefore, it is more suitable for the mixing of light materials such as grass powder.

Pelletizing

Main equipment: RICHI SZLH520 grass pellet machine

- Capacity: 3-15T/H

- Main Power: 132kw

- Finished Pellet diameter: 6-12mm

Cooling and packing

Main equipment: pellet cooling machine, automatic packing system

The temperature of the grass pellets coming out of the grass pellet machine is around 80 degrees, and the counterflow cooler can quickly bring the pellets to room temperature for the next step of packaging, improving the efficiency of the production line.

Project advantages

customization

We can see that the Indonesian customer’s raw materials include alfalfa, straw, rice husk and other crude fiber raw materials, and corn, soybean meal and other grain raw materials. Therefore, RICHI provides customers with customized solutions to meet the customer’s raw material processing and granulation.

One-stop solution

We provide customers with consulting, customized ruminant feed pellet production solutions, grass pelllet equipment manufacturing, transportation, installation, commissioning, worker training, after-sales services in all aspects. We are also grateful to the customer’s trust, which finally achieved the smooth completion and good operation of the project.

After-sales support

After the installation and commissioning of RICHI’s equipment, there will be customer service to follow up and visit the production of customers. If there are any granulation problems or equipment problems, they will be solved for customers in the first time. Our equipment has a one-year shelf life after installation, and customers can rest assured of the quality of the equipment.

RICHI MACHINERY

How to buy a RICHI grass pelletizer?

RICHI Machinery is a well-known brand of pellet machine in China, and has been in the global market for 30 years. No matter which country and region you come from, you can buy RICHI grass pelletizer.

- Send us an inquiry with your contact details and needs. For example: “hello, I’m from America, I want to produce grass pellets for burning, capacity is 2T/H. our raw materials are rice husk, corn stalk.”

- Then, we will give you the suitable solutions, equipment and the quotation. Among them, we recommend the MZLH420 grass pellet mill. In addition, you have special raw materials, such as tire fibers, we can also customize the pellet mill for the raw materials. When choosing solutions and equipment, you can choose to contact us online, or you can come to China to communicate with us face to face. Our sales staff will receive customers from different countries every day, so that customers can personally experience the enthusiasm of RICHIers, the professionalism of RICHI’s factory, and the quality of RICHI pellet equipment.

- Reach a deal, manufacturing the equipment, shipping. To ensure the safety of the customer’s property, we will choose a mutually acceptable way to conduct the transaction. The equipment will be strictly controlled in the production process, and will communicate with the customer, and ultimately ensure the quality and delivery time. Before delivery, the factory will pack the equipment without dead corners to reduce damage during transportation.

- Installation, commissioning and training. RICHI can send installation engineers and technical engineers to the customer’s factory for equipment installation and worker training. Of course, we will also provide customers with production line layout drawings, equipment installation drawings, operating instructions and so on.

Related contents of grass pellet machine

Frequently Ask Question

Frequently Ask Question

Click Here to buy now.

What machine is used to make hay pellets?

Hay pellet machine is suitable for the production of hay pellets, grass pellets, straw pellets and so on. RICHI has various hay pellet machines for sale, and can also customize machine according the capacity and size of hay pellets.

If you want to build a hay pellet production line, you also need a grass crusher, pellet cooler, hay pellet packing machine, and other auxiliary equipment. But, the grass powder drying machine is not needed.

What is the grass pellet machine cost?

The factory price of a RICHI grass pellet machine ranges from 7000-100,000 US dollars. However, bulk grass pellet production requires a production line to support. If you have the intention to purchase, you can send an inquiry to get the price list of all the equipment in the production line.

In addition, the cost of grass pellet machine in the production process includes raw materials, labor, electricity and other costs, which need to be combined with local prices to calculate.

Any Question?

You can ask anything you want to know about Feedback