Floating fish feed production line

Floating fish feed production line is mainly used for the production of floating fish feed pellets, can also produce sunking fish feed, pet feed. The core equipment of this production line is floating fish feed extruder machine.

RICHI MACHINERY

RICHI Floating fish feed production line For Sale

Floating fish feed production line purpose is to produce the good floating, water stability, and nutrient-rich extruded pellet feed.

- Extruded feed pellets are suitable for goldfish, koi, grass carp and other fish that like to be active on the water surface, and also suitable for pets.

- Main raw materials: corn, wheat, soybean meal, soybean cake, fish meal, oil, etc.

- Capacity: 0.5-60T/H

- The size of the extruded pellet: 0.6mm-20mm

- The size of floating fish feed pellets: about 1-3mm

- Main equipment: Floating fish feed extruder

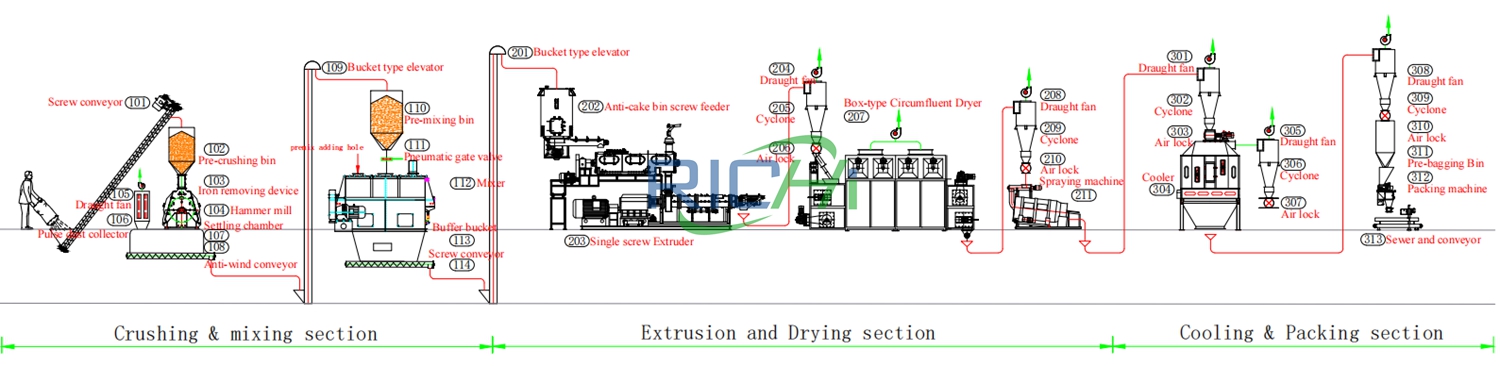

Floating fish feed production line Flow Chart

We take the high grade 1.8-2 tons per hour floating fish feed production line as an example. A standard floating fish feed production line has these processes including crushing, mixing, extrusion, drying, spraying, cooling and packing. This figure is a standard floating fish feed production line flow diagram from RICHI Machinery. Of course, you can adjust according to your own actual situation and needs. As well as, we have more plans waiting for your consultation.

Floating fish feed pellet extruder machine

As the core machine of the floating fish feed production line, the fish feed pellet machine is essential. Floating fish feed pellet extruder machine has dry method and wet method. The dry method floating fish feed extruder machine has no conditioner and does not require a boiler. However, the wet method floating fish feed extruder has a conditioner and requires a boiler to provide saturated dry steam. The high grade 1.8-2 tons per hour floating fish feed production line uses wet method floating fish feed extruder machine—single screw extruder. The more common is twins screw extruder. The capacity of twins screw extruder is 1.5-12T/H.

What are the advantages of wet method screw extruder?

Screw extruder (wet method) is mainly suitable for processing high grade floating fish feed, pet feed, and also suitable for processing submerged aquatic feed, suckling pig feed, puffed food and so on.

● 1.5-12T/H

Floating fish feed extruder machine

High quality. The cutter is made of spring steel, which fits better with the template.

Low-energy. Make full use of steam and reduce electricity consumption. Steam can also be used to supply the drying system at the back.

The open hole diameter of the extruder machine template can be customized from 0.6mm to 20mm .

● 1.5-12T/H

twin screw extruder for sale

High capacity. It is equipped with double shift differential conditioner to increase the time of powder materials inside the conditioner, so that the powder materials are fully mixed with steam to increase its degree of curing and gelatinization. The increase of maturation is conducive to digestion and absorption of fish. The increase of gelatinization degree is helpful to improve the appearance and curing degree of extruded pellets, and is also beneficial to the capacity of floating fish feed production line.

● 180kg/h-4000kg/h

floating fish feed machine

The internal temperature of the single screw extruder chamber can easily reach more than 140 degrees, and the twins screw extruder machine can reach 200 degrees.

Automatic controlling system.

Processing of submerged feed pellets. In addition to the floating extruded feed, the processing of submerged feed pellets can also be realized by changing the raw material formula or changing the screw pitch.

Hammer Mill and mixer

As with the production of livestock feed pellets, the first step in the production of floating fish feed is to crush the original pellet materials, and then the main equipment used is the hammer mill. The SFSP series hammer mill features an advanced drop-type chamber design that increases production by 25% over other models. In addition, the equipment has low vibration, low noise and high safety. The motor is a Siemens motor.

SFSP series hammer mill can be as small as 0.6mm powder size, which can meet the needs of ordinary floating fish feed production. If you have higher quality requirements for fish, shrimp and other aquatic feed, so we will use ultrafine grinder on the production line, the fineness of the powder is only about 0.15mm, which is equivalent to the fineness of flour that people eat.

The mixer is equipped with a pre-mixing bin in the mixing section of the floating fish feed production line. Mixer Before the powder materials enter the floating fish feed extruder, it is necessary to add the premix and let them get a uniform and full mix. The mixer is to mix the powder materials according to the batch. According to the effective volume and the density of the powder material, each batch has 250kg, 500kg, 1T, 2T, etc. We can choose the mixer according to the capacity of the floating fish feed production line.

Dryer And Spraying Machine

The water content of the floating fish extruded feed pellet coming out of the floating fish feed extruder machine is about 18%-20%, mainly because the operation of the screw extruder machine has high water content requirements for raw powder materials. Later, a dryer is needed to dry the moisture of the extruded pellets to the content we require – about 11%. The box-type circumfluent dryer allows the hot air to circulate in the box, making full use of the heat energy. In addition, in the process of hot drying, the floating fish feed pellets are also re-cured.

The role of the spraying machine in the floating fish feed production line is to spray oil to the floating fish feed pellets to increase their fat content. The method of thermal spraying makes it easier for the oil to flow and penetrate into the floating fish feed. Oil injection is helpful to increase the heat of feed, improve the taste of feed, extend the shelf life of feed, and promote the digestion and absorption of aquatic animals. Wind transport can be used on small production lines, and then bucket type elevators or screw conveyors or customized conveyor can be selected for large production.

Advantages of floating fish feed

An efficient, environmentally friendly and easy to manage feed choice.

01

Improving the utilization rate of fish feed and reducing breeding cost

Floating fish feeds have less dense and can be suspended on the surface for a long time. They are easy to get used to fish eating on the surface of the water, and it is easy for the keeper to observe the eating situation of the fish, adjust the feeding amount in time, and avoid the waste of fish feed pellets.

02

Promoting the growth of fish, Easy to store and transport

The extruded feed pellets produced by the floating fish feed extruder have a higher degree of maturation, which is conducive to the digestion and absorption of fish and reduces the incidence of disease. The feed formula is reasonable to provide adequate nutrition for fish.

03

Providing a good living environment for fish

Floating fish feed has little effect on water quality. First, because the floating fish feed will not dissolve in water for a long time, and second, through high temperature has killed most of the harmful microorganisms. Good water quality is indispensable for fish growth.

More Floating Fish Feed Production Line Solutions

If you also need to build floating fish feed production line, shrimp feed production line, animal feed production plant, you can send us an inquiry.

If you have any questions about granulation, such as how to make floating fish feed, you can also ask us.

1-2 t/h floating fish and shrimp feed production line in Iran

The price of the line is about 330,000 dollars. This line can produce both floating and sinking feeds.

Project details

The customer, a well-known multinational enterprise of aquatic products in Iran, sent an inquiry to RICHI Machinery on December 27, 2021. The Iranian customer expressed to us the need to build a 2t/h floating fish feed and shrimp feed pellet production line and provided us with the dimensions of the plant. After more than three months of communication, as well as the comparison and consideration of the customer, the project was determined on April 19, 2022.

The 1-2 t/h floating fish feed and shrimp feed pellet production line includes crushing system, mixing system, pelletizing and extruding system, packing system and electric control system.

The using of RICHI pulse dust collector can reduce dust in the working space.

fish feed extruder

In the pelletizing and extruding system, the making of floating fish feed uses RCPH120*2 twins screw extruder, the making of shrimp feed uses SZLH420 animal feed pellet mill with 3-layer stainless steel conditioner. The gelatinization degree becomes higher, which is conducive to granulation.

shrimp feed Pellet machine

The 3-layer conditioner can prolong the condition time and increase the degree of maturation and gelatinization of shrimp materials. The higher degree of ripening is conducive to the digestion and absorption of shrimp.

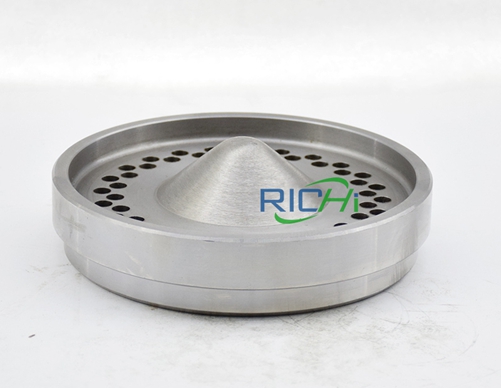

Ring dies of pellet machine

We equip the customer with the ring mold with different apertures. The ring die apertures of the SZLH 420 animal feed pellet mill are 1mm, 1.5mm, 2mm, 3mm, 4mm, 6mm respectively. Shrimp feed pellet size is about 1.2mm -3mm.

Dies of Extruder

The die apertures of RCPH120*2 twins screw extruder are 0.6mm, 1mm, 1.5mm, 2.0mm, 3.0mm, 4.0mm, 6.0mm, 8.0mm, 10.0mm, 12.0mm, 16.0mm, 20.0mm respectively. Customers can produce feed pellets of different sizes.

Why did the Iranian client choose RICHI?

Floating fish and shrimp feed production line

1

The Iranian customer has already well versed in aquatic products and has compared several companies in the construction of floating fish feed production line or shrimp feed pellet prodution line. We let our customers realize the production of floating fish feed and shrimp feed in the most economical way.

2

The customer is satisfied with the quality of RICHI’s machines. The material of our equipment is relatively good, for example, all the parts of the SZLH series animal feed pellet mill in contact with the materials adopt stainless steel, which is not easy to pollute the feed. Our machines have advanced technology and user-friendly design in many places.

3

The customer is more approved of our production scheme. We can customize cost-effective solutions for customers according to their site and production needs, especially the production of floating feed and sinking feed on the same production line. Eliminate unnecessary investment and maximize production line utilization.

4

The program we developed for our Iranian customer enables the production of floating fish feed and shrimp feed with minimal machinery and investment. The production line can not only produce aquatic feed, but also produce chicken feed pellets, cattle feed pellets.

5

Keep track of the progress of the float fish feed production line and shrimp feed pellet production line. The production cycle of the project is 60 days, the shipping time is 40 days, and the installation cycle is 90 days. From the first enquiry, we maintain effective communication with our clients until the end of the project.Regular Voice or video to report machine production progress to customers.

6

RICHI has more successful cases of floating fish feed production lines and aquatic feed production lines, providing a strong reference for the establishment of new production lines.