Floating fish feed extruder machine

Floating fish feed extruder machine is the core production equipment of high-grade floating fish feed production line, mainly used to produce floating fish feed, also can produce pet food, slow sinking feed and sinking feed. Usually, the floating fish feed extruder machine has single screw or twin screw extruder, wet type and dry type fish feed extruder. If you want to buy a floating fish feed pellet extruder machine or understand the fish feed extruder process, here may be able to help you.

RICHI Floating fish feed extruder machine for sale

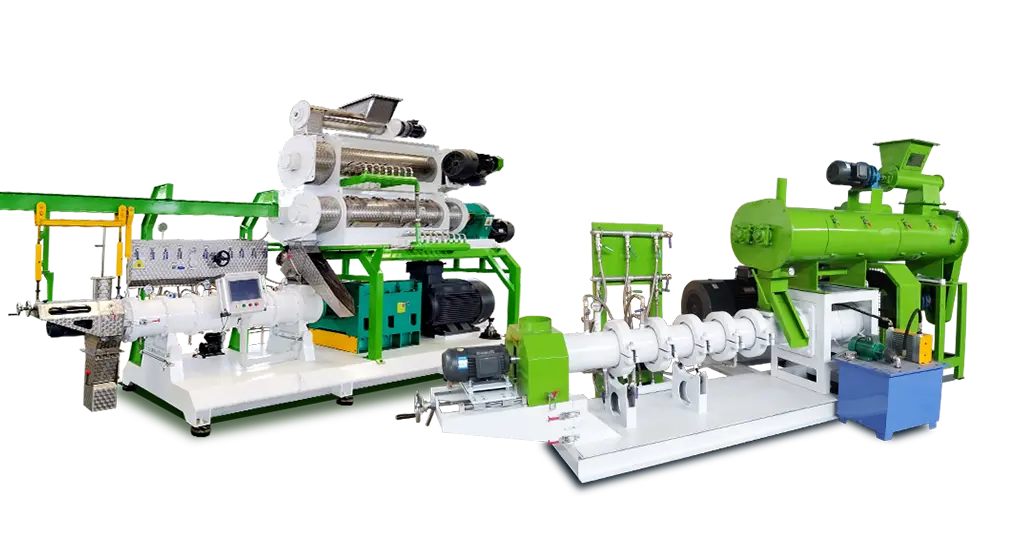

Taking into account the different needs and budgets of customers, RICHI Machinery provides multiple models of fish feed pellet extruder, including RCPH series twin screw extruder and DGP&DSP series single screw extruder.

RCPH series twin screw extruder for sale

This series of fish feed pellet extruder is the latest developed by RICHI Machinery according to the modern aquaculture characteristics of floating fish, with high capacity, good performance and high automation. This series of extruder machines are equipped with DDC-conditioner, belonging to wet type extruder machine.

The capacity is 1.5-12T/H. Suitable for customers with high demand for fish feed production and quality.

DGP&DSP single screw extruder

This series of extruder machines are single-screw extruder, there are dry type extruder and wet type extruder. The dry fish feed extruder can eliminate the boiler system, and the capacity is 0.03-2T/H. The wet type fish feed extruder uses a different diameter conditioner, and the capacity is 0.18-4T/H.

The price of fish feed extruder machine is lower, small investment, low energy consumption, widely used.

Why use a floating fish feed extruder machine to produce fish feed?

We look at the raw materials as well as the advantages of extruded feed pellets that are ultimately produced.

Abundant raw materials

The raw materials that can be processed by the fish feed pellet machine include fish meal, soybean meal, corn meal, wheat flour, premix, etc., which contains the protein, energy, lipids, trace elements and so on that are needed for the growth of fish. In the processing technology of extruded feed, the appropriate feed formula will be configured according to the fish type, size, water temperature, feeding method, etc.

Promote the growth of fish

The crushing size of the feed used for extrusion is finer, the protein deformation can be more fully, the starch gelatinization can be more fully, the final extruded feed pellets are more mature, and will be sprayed with oil. Therefore, the extruded feed granules can promote the growth of fish and have better palatability.

Easy to manage

Floating fish feed pellets are characterized by floating on the surface of the water, ideal for growing in warm water, as well as surface feeding fish, such as tilapia, eels, catfish, carp, etc. The extruded feed floating on the water is easier to observe, and the feeders can better control the feeding amount. In addition, reduce the pollution to the water body and extend the life of the fish.

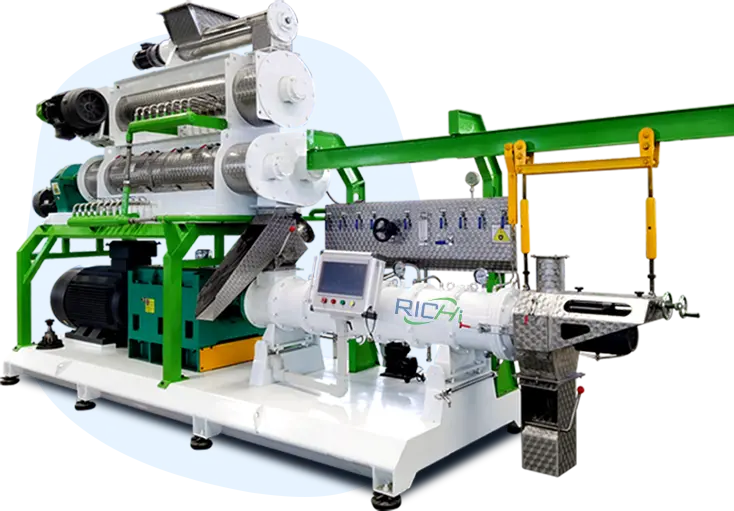

Features of RCPH series twin screw extruder

— Richi Machinery —

RCPH series floating feed making machine is mainly composed of anti-caking bin, inverter feeder, conditioner, DDC, twin screw extruder and PLC controlling system. The feed raw materials are processed by steam, high temperature, extrusion and shearing force, and the fluffy materials are instantly extruded from the opening of the die, and the extruded feed pellets are finally formed after cutting with the cutter. The final extruded feed pellets have a neat appearance and better water resistance.

Final extruded feed pellet diameter: 0.6-20mm

Anti-caking bin

Ensure that the fish feed with small crushing size is not arched when entering the feeder.

Inverter feeder

The materials are evenly fed into the conditioner without blocking the machine and idling.

DDC-Conditioner

Using double-shaft differential conditioner makes the material more fully mixed with water vapor, and the degree of curing and gelatinization is higher.

Twin screw extruder

Using new-type all-wear-resistant screw and bimetal expansion cavity inner sleeve, high production capacity, high quality, stable operation.

Die

Die aperture is 0.6-20mm, suitable for high-grade floating fish and sinking fish feed, pet food, puffed food and so on.

PLC controlling system

The machine uses PLC and touch screen control, high precision, high automation, easier operation, saving manpower.

Model and parameters of RCPH floating fish feed extruder machine

Here are mainly introduced 6 floating fish feed extruder machine models, the capacity is between 1.5T/H and 12T/H. Of course, we can customize machines for our customers.

Twin screw extruder for sale

- Model: RCPH120*2

- Capacity: 1.5-2T/H

- Main power: 75kw

- Screw diameter: 120mm

- Conditioner model and power: /

- DDC model and power: DDC400/300/244 with 11kw

floating fish feed extruder machine

- Model: RCPH120*2

- Capacity: 3-4T/H

- Main power: 90kw

- Screw diameter: 120mm

- Conditioner model and power: DC420/244 with 7.5kw

- DDC model and power: DDC400/300/244 with 11kw

fish feed pellet extruder

- Model: RCPH150*2

- Capacity: 4-5T/H

- Main power: 160kw

- Screw diameter: 150mm

- Conditioner model and power: DC500/244 with 11kw

- DDC model and power: DDC500/400/244 with 11kw

fish food extruder machine

- Model: RCPH150*2

- Capacity: 6-7T/H

- Main power: 200kw

- Screw diameter: 150mm

- Conditioner model and power: DC500/244 with 11kw

- DDC model and power: DDC500/400/244 with 11kw

floating fish feed making machine

- Model: RCPH185*2

- Capacity: 8-10T/H

- Main power: 315kw

- Screw diameter: 185mm

- Conditioner model and power: DC600/300 with 15kw

- DDC model and power: DDC500/300/300 with 15kw

price of fish feed extruder machine

- Model: RCPH185*2

- Capacity: 10-12T/H

- Main power: 355kw

- Screw diameter: 185mm

- Conditioner model and power: DC600/300 with 15kw

- DDC model and power: DDC500/300/300 with 15kw

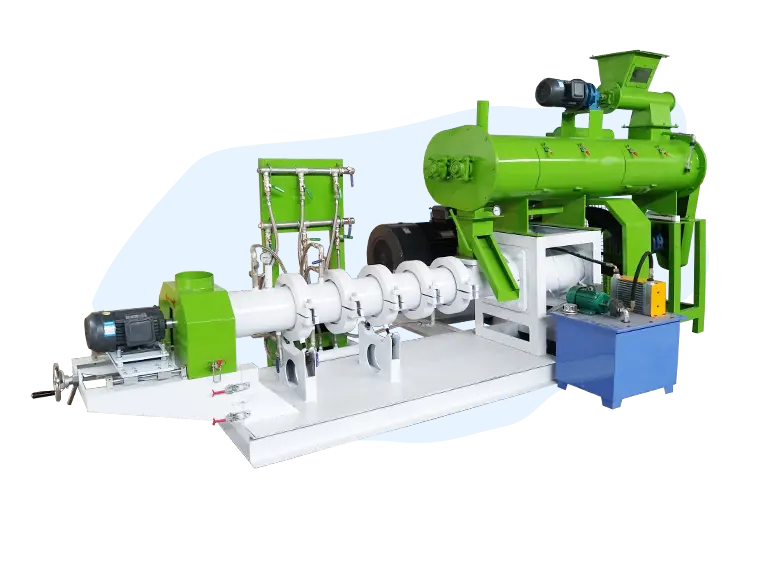

Features of RICHI single screw extruder

— Richi Machinery —

RICHI single screw floating fish feed extruder is suitable for floating fish feed, sinking fish feed, shrimp feed, crab feed, suckling pig feed, pet feed production.

- Type: DGP dry type fish feed extruder and DSP wet type extruder

- Capacity: 0.03T/ H-4t /H

- Price of fish feed extruder machine: $2,000 – $40,000

- Main components: variable frequency feeder, conditioner, single screw, PLC system (dry type fish feed extruder machine without conditioner)

Advantages:

- The operation is simple, the price is cheap and the application is wide.

- Variable frequency feeding, free speed regulation.

- DSP wet type extruder machine adopts a new type of conditioner to make the material more fully modulated. The DGP dry type extruder does not require steam and is suitable for small volume users who do not want a boiler.

- Stable performance, good operation, the production of floating fish feed and pet feed have good appearance and high curing degree.

Parameter table of RICHI dry type fish feed extruder

| Model | Capacity(t/h) | Main motor power(kw) | Feeder power(kw) | Screw diameter(mm) | Cutter power(kw) |

| DGP40-Cs | 0.03-0.04 | 3.0*2 | 0.4 | Φ40 | 0.4 |

| DGP40-C | 0.03-0.04 | 5.5 | 0.4 | Φ40 | 0.4 |

| DGP50-C | 0.06-0.08 | 11 | 0.4 | Φ50 | 0.4 |

| DGP60-C | 0.12-0.15 | 15 | 0.4 | φ60 | 0.4 |

| DGP70-B | 0.18-0.2 | 18.5 | 0.4 | φ70 | 0.4 |

| DGP80-B | 0.2-0.25 | 22 | 0.4 | φ80 | 0.6 |

| DGP90-B | 0.30-0.35 | 37 | 0.6 | φ90 | 0.8 |

| DGP120-B | 0.5-0.6 | 55 | 1.1 | φ120 | 2.2 |

| DGP135-B | 0.7-0.8 | 75 | 1.1 | φ133 | 2.2 |

| DGP160-B | 1-1.2 | 90 | 1.5 | φ155 | 3 |

| DGP200-B | 1.8-2.0 | 132 | 1.5 | φ195 | 3.0-4.0 |

Parameter table of RICHI DSP single-screw fish feed extruder

| Model | Capacity(t/h) | Main motor power(kw) | Feeder power(kw) | Screw diameter(mm) | Cutter power(kw) | Conditioner power(kw) |

| DSP60-B | 0.18-0.2 | 15 | 0.4 | Φ60 | 0.4 | 0.75 |

| DSP70-B | 0.25-0.30 | 18.5 | 0.6 | Φ70 | 0.6 | 0.75 |

| DSP80-B | 0.35-0.40 | 22 | 1.1 | Φ80 | 0.8 | 1.1-1.5 |

| DSP90-B | 0.50-0.60 | 37 | 1.1 | Φ90 | 1.1 | 2.2 |

| DSP120-B | 0.70-0.80 | 55 | 1.1 | Φ120 | 1.5 | 2.2-3.0 |

| DSP135-B | 1.0-1.2 | 75 | 1.5 | Φ135 | 2.2 | 3.0-4.0 |

| DSP160-B | 1.8-2.0 | 90 | 2.2 | Φ155 | 2.2-3.0 | 4.0-5.5 |

| DSP200-B | 3.0-4.0 | 132 | 2.2 | Φ195 | 3.0-4.0 | 5.5 |

| DSP200-B | 3.0-4.0 | 132 | 2.2 | Φ195 | 3.0-4.0 | 5.5 |

Related cases of Floating fish feed extruder machine

As a manufacturer and exporter of quality brand floating feed making machine, RICHI’s customers have spread all over the world and have made great contributions to the development of fish feed production equipment.

10T/H floating fish feed machine in China

1.5-2T/H floating fish feed extruder in Russia

150KG/H dry fish feed extruder machine in Nigeria

0.5T/H floating fish feed making machine in Botswana

5T/H aquatic feed mill in United States

2T/H floating fish feed plant in Philippines

1T/H floating fish feed and crab feed mill in Canada

1T/H pet food production line in Malaysia

What is the process of fish feed extrusion?

— Floating fish feed extrusion process —

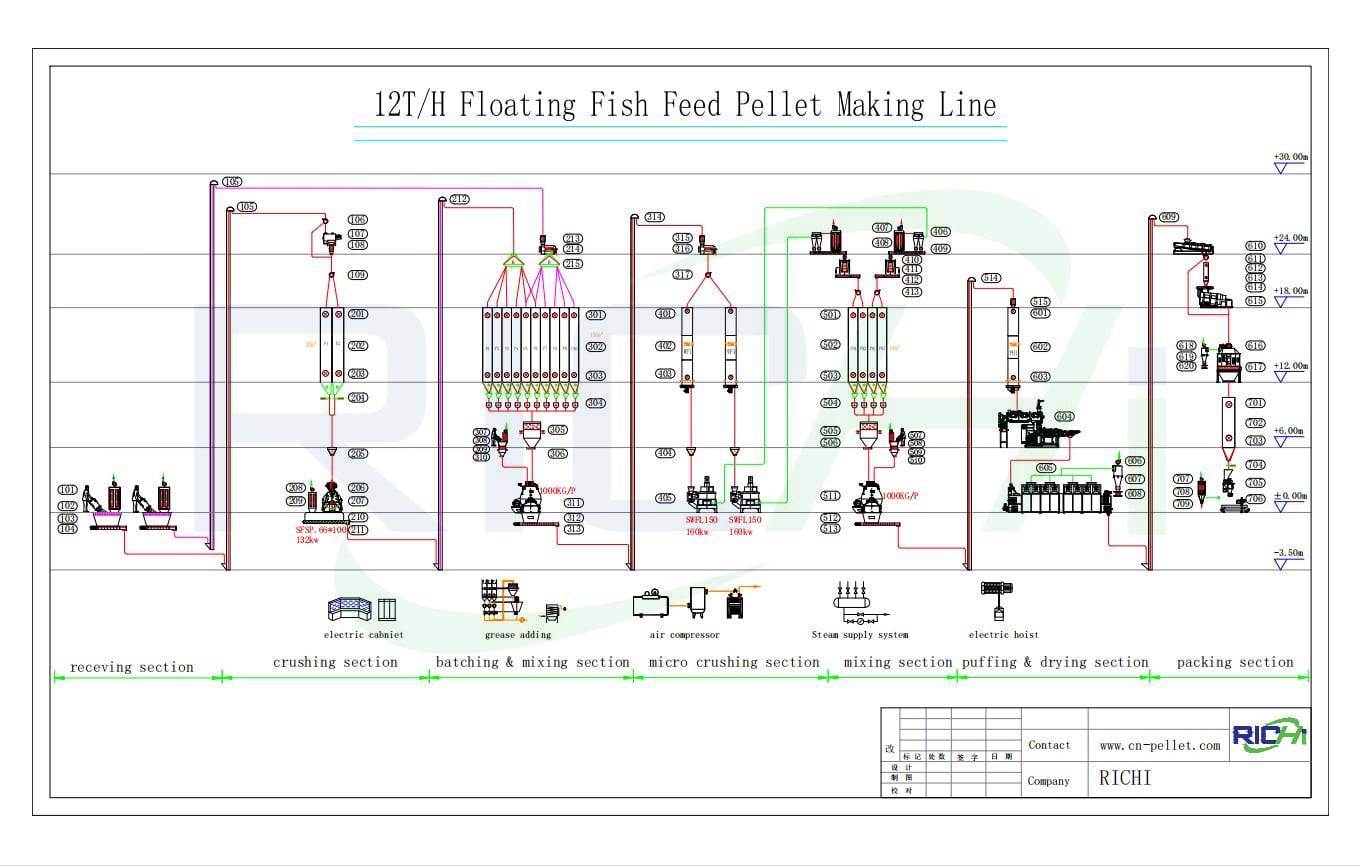

The production line is used for the production of 12T/H floating fish feed, the main sections are:

Raw material receiving section – rough crushing section – batching and mixing section – micro crushing section – secondary mixing section – puffing and drying section – packaging section

Process features:

- The production line adopts a fully automatic batching system, which has higher batching accuracy and can also save manpower.

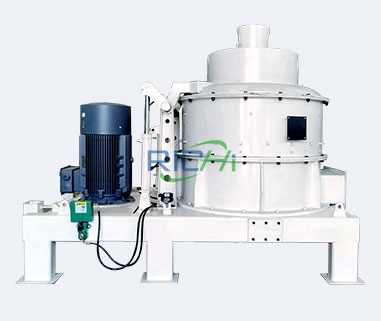

- The micro crushing section adopts two ultrafine grinding machines, which can crush the feed as fine as flour, which is conducive to the expansion process of feed.

- After the extruding section, the dryer and spraying machine will dry the extruded pellets in time and spray the grease while it is hot.

- Richi can customize high-grade floating fish feed and aquatic feed production line solutions for customers, for the production of fish, shrimp, crabs and other feeds.

Auxiliary equipment of Floating fish feed plant

— Richi Machinery —

Extruded feed dryer

Expanded pellet sprayer

Expanded pellet cooling machine

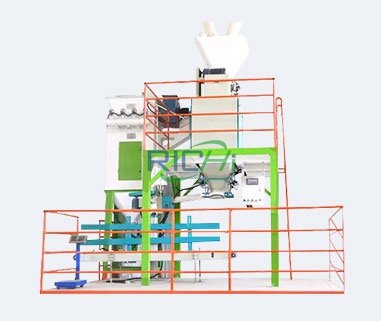

Extruded pellet packing machine

Frequently Ask Question

Frequently Ask Question

Click Here to buy now.

What is the difference between floating and sinking fish feed?

Floating fish feed is a floating feed that floats on the surface of the water and is convenient for fish that like to move in the upper water. Float fish feed is usually puffed feed, more mature, better water resistance, higher fat content. As a result, the fish can absorb better and grow faster. In addition, the feed on the water surface is more conducive to observation, and the feeding amount can be well controlled.

Sinking fish feed refers to the fish feed that can be sunk on the bottom to facilitate the feeding of groundfish. Because feed sinks in water, sinking fish feed often requires higher water resistance. In addition, sinking fish feed can avoid food competition and waste. The production of sinking fish feed can be done by fish feed pellet machine or by extruder machine. floating fish feed plants can choose according to their own situation.

So, what are the factors affecting the production of floating and sinking fish feed by fish feed extruder?

They mainly include screw, template opening area ratio, temperature and pressure in extruder, steam and water, starch content and fat content. Taking the starch content of raw materials as an example, the starch content of processed floating fish feed is at least 20%. The bulk weight of the floating feed after extrusion is 320g-400g/L. The bulk weight of the submerged fish feed is 450-550g/L. In addition, sinking feed is not suitable for excessive drying, otherwise it may float.

Any Question?

You can ask anything you want to know about Feedback

RICHI Advantages

RICHI has advantages in product quality, project experience, equipment cost and service, and is the leading manufacturer of floating fish feed machine in China.

Product Quality

RICHI’s floating fish feed extruder has passed CE and ISO quality certification, and the factory has also passed more than 20 patents in mechanical production, which is a strong competitive mechanical equipment.

Project Experience

We have built more than 1,000 turnkey projects in 127 countries around the world, helping customers solve a variety of feed production and equipment problems, with 30 years of experience.

Equipment Cost

Cost performance is what we always insist on, in the quality and process control, we have been committed to saving customer costs. Adhere to the concept of win-win cooperation and create a better future together.

One-Stop Service

From consulting services, project analysis, design, proposal, equipment manufacturing to installation training, after-sales service, customers can buy floating fish feed extruder or build a floating fish feed plant without worry.

500+

500+ device models

1000+

1000+ turnkey projects

127+

127+ countries and regions

2000+

2000+ customers

Global project cases

We have built floating fish feed extruder machine related project cases and the customer feedback, hope to help you. Contact us for more details.

100-150kg/h floating fish feed extruder in Ukraine

- Project start date: January 4, 2019

- Total power: 50.74kw

- Customer raw materials: soybean meal, wheat, fish meal, black meal, corn

- Finished pellet diameter: 3mm, 4mm, 5mm, 6mm, 8mm, 10mm

- Main equipment: fish feed crusher, mixing machine, floating fish extruder, dryer, spraying machine

- Customer feedback: Very good. Help us to adjust the fish feed formula, and finally the puffed feed pellets successfully floated.

1T/H floating fish feed and chicken feed production line in Uzbekistan

- Project start time: January 2019

- Total power: 150kw

- Customer raw materials: corn, soybean meal, oil, premix

- Finished pellet diameter: 2-12mm

- Main equipment: feed crusher, mixer, floating fish feed extruder machine, chicken feed pellet machine, cooling machine, automatic packaging machine

- Customer feedback: A production line complete can produce two types of feed, cost-effective, thanks to RICHI.

1-2T/h floating fish and shrimp feed production line in Iran

- Project start date: April 19, 2022

- Customer raw materials: fish meal, soybean meal, corn, wheat, premix

- Finished pellet diameter: 0.6-20mm

- Main equipment: RCPH120*2 twins screw extruder, shrimp feed making machine, feed crusher, screw belt mixer, pellet cooling machine, sewing and belt conveyor

- Customer feedback: The floating fish feed extruder machine and aquatic feed production line is one of the investments made by our company, and the current operation is satisfactory, looking forward to the next cooperation.