Fish feed pellet machine price

Fish feed pellet machine price varies according to brand, type, model, capacity and configuration. For example, RICHI SZLH series fish feed pellet machine prices range from $10,000 to $100,000, RICHI RCPH series fish feed pellet extruder prices range from $50,000 to $210,000, RICHI floating fish feed single screw extruder prices range from $2,000 to $40,000. RICHI fish feed pellet machine can produce sinking fish, floating fish, shrimp, crabs and other aquatic feed and pet feed. If you want to buy a machine for producing fish feed or pet food, you can contact us.

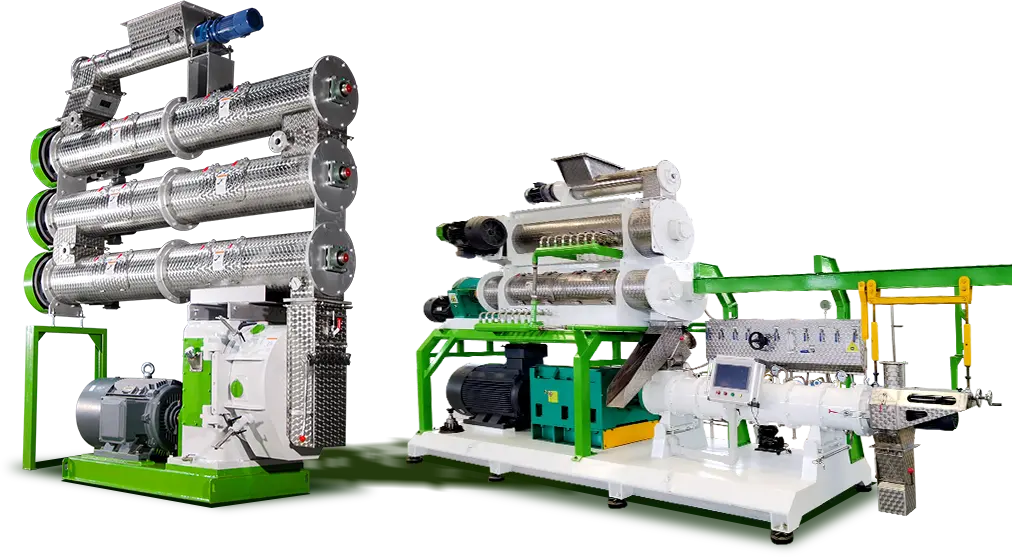

RICHI SZLH series sinking fish feed pellet machine Price

This series of fish feed pellet making machine is improved based on RICHI SZLH animal feed pellet machine. The fish feed pelleting machine price is also slightly different on its basis, but it is still between $10,000 and $100,000, fish feed pellet making machine is a cost-effective machine.

- Main applications: production of sinking fish feed, such as catfish, demersal fish, shrimp, etc.

- Processable raw materials: fish meal, poultry by-product, soybean meal, feather meal, wheat meal, corn meal, fish oil, rapeseed oil, vitamins, minerals, etc.

- Model: SZLH250, 320,350,420,508,558,678,768,858

- Capacity: 0.6-30 tons/hour

- Main motor power: 22-355kw

- Type: Ring die granulator

- Pellet diameter: 1.5-12mm (usually 1.5-3mm for sinking fish feed)

- Conditioner: 2-3 layers

- Customizable: yes

- Equipment features: The fish feed pellet machine is equipped with 2-3 layers of specially designed conditioner, so that the fish or shrimp feed can be more fully modulated and matured, which is conducive to the digestion and absorption of fish and shrimp. Roller, ring die, cutter and other accessories are also upgraded according to the characteristics of fish and shrimp feed, enhance the stability of fish feed pellets in water, not easy to be broken down.

RICHI SZLH series sinking fish feed pellet machine price and parameter

— Richi Machinery —

To meet our customers’ different budgets and fish feed production needs, we manufacture a variety of fish feed pellet making machines. You can choose the machine that suits you according to your actual situation. We can also customize fish feed pellet machines for you in other specifications and capacity.

| Model | Price (US Dollars) | Capacity(TPH) | Main Motor Power(kw) | Feeder Motor Power(kw) | Conditioner Power(kw) | Dia.of Ring Die(mm) | Final Pellet(mm) |

| SZLH250 | 7,000 -10,000 | 0.6-1.4 | 22 | 0.75 | 1.5 | 250 | 1.5~12 |

| SZLH320 | 15,000 -20,000 | 1.8-2.8 | 37 | 1.5 | 2.2 | 320 | 1.5~12 |

| SZLH350 | 20,000 -30,000 | 3-5 | 55 | 1.5 | 3 | 350 | 1.5~12 |

| SZLH420 | 30,000 -40,000 | 4.8-8.5 | 90 | 1.5 | 7.5 | 420 | 1.5~12 |

| SZLH508 | 40,000 -60,000 | 6-12.5 | 132 | 2.2 | 11 | 508 | 1.5~12 |

| SZLH558 | 60,000 -70,000 | 9-17.5 | 180/200 | 2.2 | 11 | 558 | 1.5~12 |

| SZLH558D | 60,000 -80,000 | 8.4-15.5 | 160/180/200 | 1.5 | 7.5 | 558 | 1.5~12 |

| SZLH678 | 70,000 -80,000 | 12-21 | 220/250 | 2.2 | 11 | 678 | 1.5~12 |

| SZLH678D | 60,000 -80,000 | 9-17.5 | 200/220/250 | 2.2 | 11 | 673 | 1.5~12 |

| SZLH768 | 80,000 -90,000 | 15-28 | 280/315 | 2.2 | 11 | 768 | 1.5~12 |

| SLZH858 | 90,000 -100,000 | 15-30 | 280/315 | 2.2 | 15 | 858 | 1.5~12 |

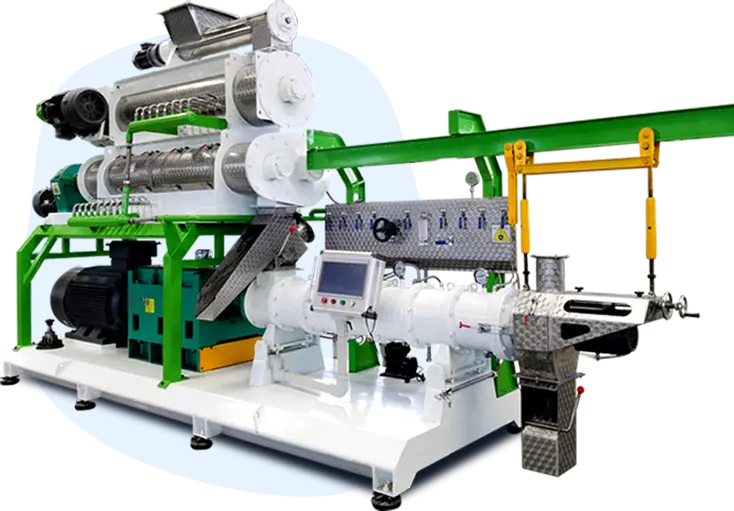

RICHI RCPH series fish feed pellet extruder

This series of fish feed pellet extruder belongs to twin-screw extruder, which is the first choice of medium and large fish feed plant. This is a high-grade fish feed production equipment, ranging in price from $50,000 to $210,000.

- Main applications: floating fish feed, slow sinking fish feed pellets, sinking fish feed, cat food, dog food and other pet feed, semi-wet feed.

- Processable raw materials: fish meal, shrimp meal, meat and bone meal, chicken meal, coarse blood meal, soybean meal, peanut meal, cottonseed meal, flaxseed meal, wheat flour, corn meal, corn gluten meal, bentonite, rice bran, dry yeast, malt root, etc.

- Model: RCPH120*2, RCPH150*2, RCPH185*2

- Capacity: 1-12T/H

- Main motor power: 75-355kw

- Type: Twin screw extruder

- pellet diameter: 0.6mm-20mm

- Conditioner: Differential speed conditioner

- Customizable: yes

Equipment features:

- PLC control system, easy to operate.

- Widely used. Adjusting the starch content of the raw material, the screw L/D and the template opening area ratio can realize the production of sinking feed, slow sinking feed and floating feed.

- The higher degree of maturation, the production of fish feed pellets and pet feed pellets more delicious.

- The fish feed twin-screw extruder adopts a new all-wear-resistant alloy screw and a bimetal expansion chamber of the inner sleeve, which reduce the wear of the main working parts and increases the life of the machine.

RICHI RCPH series fish feed pellet extruder price and parameter

The following is a list of 6 commonly used fish feed twin-screw extruder models introduced by RICHI. If you have more specific needs, you can send an inquiry to tell us, we can design and customize special machines for you.

| Model | RCPH120*2 | RCPH120*2 | RCPH150*2 | RCPH150*2 | RCPH185*2 | RCPH185*2 |

| Price (US Dollars) | 50,000-70,000 | 60,000-90,000 | 100,000-140,000 | 120,000-150,000 | 160,000-200,000 | 170,000-210,000 |

| Capacity(T/H) | 1-2 | 3-4 | 4-5 | 6-7 | 8-10 | 10-12 |

| Main motor power(KW) | 75 | 90 | 160 | 200 | 315 | 355 |

| Diameter of the screw(mm) | 120 | 120 | 150 | 150 | 185 | 185 |

| Conditioner Model | / | DC420/244 | DC500/244 | DC500/244 | DC600/300 | DC600/300 |

| Conditioner power | / | 7.5 | 11 | 11 | 15 | 15 |

| Matching Differential-Speed Conditioner Model | DDC400/300/244 | DDC400/300/244 | DDC500/400/244 | DDC500/400/244 | DDC500/300/300 | DDC500/300/300 |

| DDC conditioner power(KW) | 11 | 11 | 11 | 11 | 15 | 15 |

RICHI MACHINERY

Fish feed pelletizer project cases and prices

RICHI Machinery has completed a lot of sales of fish feed pellet making machines at home and abroad, and helped customers build fish feed plants. Our projects have covered 127 countries and regions.

Production Line for 1.5-2T/H Extruding Fish Feed/Pet food & 5-6 T/H Animal Feed

- Country: Iran

- Date: April 19, 2022

- Guide Price: 330,000 US Dollars

- Main Equipment: RCPH120*2 Twin screw extruder, SZLH420 shrimp feed pellet machine; SFSP66*60 fish feed hammer mill, SLHY1.0A fish feed mixing machine, JBS-50 customized conveyor, SKLN17*17 shrimp feed pellet cooling machine, DCS-50 auto-packing machine

- Dies for fish feed extruder: 0.6mm, 1.0mm, 1.5mm, 2.0mm, 3.0mm, 4.0mm, 6.0mm, 8.0mm, 10.0mm, 12.0mm, 16.0mm, 20.0mm

- Ring die for shrimp feed pellet machine: 0.5mm, 1.0mm, 2.0mm, 3.0mm, 4.0mm, 6.0mm

5-6 tons per hour floating fish feed production line

- Country: Russia

- Date: August 17, 2021

- The fish feed mill plant cost: 1.3 million US Dollars

- Main equipment: stainless steel fish feed mixer, ultrafine grinder, RCP125*2 twin screw extruder (customized), HGJW2000*4 mesh belt fish feed pellet dryer, SSLG20*140X pellet crumbler, SFJH100*2 fish pellet screener, SKLN17X17 pellet cooler

- Features: The whole production line is controlled by computer computer system.

2T/h shrimp feed making machine in Indonesia

- Country: Indonesia

- Guide Price: $600,000

- Date: June 2, 2022

- Main equipment: batching system, fish feed mixer, ultrafine grinder, RICHI SZLH shrimp feed pellet making machine, pellet cooler, automatic packing system

Note:

- Customers should be equipped with transformers with a total power of 0.7 or more to ensure the safe operation of the shrimp feed pellet production line.

- This customer has placed an order for additional aquatic pellet lines with our company in 2024.

How are fish feed pellets produced with new technologies?

— Richi Machinery —

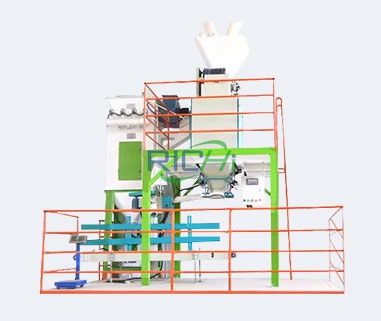

As the main machine of fish feed pellet production line or fish feed plant, fish feed pelletizer machine presses mixed fish feed into fish feed pellets. However, the production of fish feed pellets requires the entire production line to complete.

The main sections of the fish feed pellet production line include: raw material reception, raw material crushing, batching according to the formula, mixing of powder feed, adding of small materials, granulation or extruding, drying, cooling, screening of fish feed pellets, and finally packaging of fish feed pellets.

Tips:

- Fish and shrimp feed requires a smaller crushing size, so an ultrafine grinder is used for secondary crushing.

- After drying, the extruded fish feed pellets will be sprayed with grease by spraying machine, so that the grease will go deep inside the pellets while they are hot, increase pellet grease content, and help the rapid growth of fish and shrimp.

- The above sections provided by RICHI Machinery for customers are modular, and customers can choose and customize according to their needs.

Fish feed pellets production line equipment and prices

— Richi Machinery —

We see that fish feed production not only needs fish feed pellet machine and fish feed extruder machine, but also needs more auxiliary equipment. Together to understand these equipment and their prices.

Fish feed hammer mill Price: $5,000-35,000

Ultrafine grinder price: $30,000-70,000

Fish feed mixer price: $2,500-40,000

Fish feed pellet dryer price: $100,000-220,000

Spraying Machine

Fish feed pellet cooler price: $4,000-20,000

Vibrating screen price: $2,000-10,000

Packing scale price: $5,000-10,000

Frequently Ask Question

Frequently Ask Question

Click Here to buy now.

What are the differences between fish feed pellet machine and fish feed extruder? Which is worth investing in?

Fish feed pellet machine is mainly used for the production of sinking fish feed and shrimp feed pellets. High density fish feed pellets are formed through the extrusion of ring die and press roller. Compared with the fish feed extruder, the fish feed pelletizer machine has lower price, higher output and easier return on investment.

Fish feed extruder can produce floating fish feed, sinking fish feed, slow sinking fish feed, dog food, cat food, hamster food, pet food and so on. Extruded feed pellets are extruded from die mouth by high speed rotation of screw and high temperature and high pressure environment. The higher temperature and pressure in the extruding process can improve the gelatinization of starch in feed, change the structure of protein and improve the utilization rate of feed. Floating feed on the water surface, better stability, easy to feed, reduce feed waste. In addition, the current profit of extruded feed is higher, in the long run, the investment of fish feed extruder machine project is more profitable.

How much does invest in fish feed mill plant cost?

Now let’s discuss what it costs for RICHI to build a fish feed mill plant project for a customer, excluding the infrastructure of the fish feed plant, the local labor and water and electricity costs.

- Fish feed pellet machine price, auxiliary equipment price.

- Cost of steel frame.

- Boiler system, oil adding system, air compressor, gas storage tank price.

- Transportation costs.

- Installation and commissioning costs.

- Others.

The above is basically the net fish feed mill plant cost, and the specific need to combine your own project size, equipment brand and so on to decide.

If you want to invest in fish feed pellet machine project, contact us quickly for a detailed list and quotation.

Any Question?

You can ask anything you want to know about Feedback

RICHI MACHINERY

More related global cases of fish feed pelletizer machine

5-7T/H fish feed pellet line in Indonesia

150,000 Tons per year aquatic feed line and silo in Henan, China

5T/H fish feed pelletizer machine in Ecuador

5T/H sinking fish feed pellet line in Uzbekistan

Bolivia 2T/H fish feed pellet extruder

2-3T/H tilapia feed pellet machine in India

1T/H sinking fish feed pellet line in Turkey

1T/H floating fish feed pellet production line in malaysia

100-150kg floating fish feed extruder in the UK

Thailand 1T/H sinking fish feed pellet line

Cote d ‘Ivoire 300-400kg floating fishing feed line

WHY CHOOSE RICHI?

RICHI Machinery has been operating for 30 years, is the most professional fish feed pellet machine manufacturer, supplier and exporter in China, and provides the factory price directly to customers.

RICHI Strength

Richi’s fish feed pellet machine and auxiliary equipment have passed ISO, CE and other international certifications, and also passed BV factory inspection.

Rich Experience

We have built animal feed and fish feed pellet production lines for more than 2,000 customers in more than 127 countries and regions around the world.

Cost-Effective

If you know the same type of fish feed pelleting machine price, you will be happy to choose RICHI Machinery.

4R Service

Reliability, rigorousness, responsiveness and reassurance. Our goal is that every customer is worry-free all the way. You can also choose us with confidence.

500+

500+ device models

1000+

1000+ turnkey projects

127+

127+ countries and regions

2000+

2000+ customers