Fish feed mill plant

Fish feed mill plant uses advanced equipment and technology to produce high-quality fish, shrimp, crabs and other aquatic feed, which has played a great positive role in the development of fisheries and the economic benefits of aquaculture. RICHI’s business is to provide effective solutions and high-quality production equipment for fish feed mills, including plant construction consultation, production line design, fish feed mill machine manufacturing, equipment installation, etc.

Brief of Fish feed mill plant built by RICHI Machinery

RICHI Machinery is a professional fish feed plant manufacturer, which can design, upgrade, transform, build and install for large, medium and small fish feed mills of different sizes and types.

- Feed mill capacity: 0.5-60T/H

- Finished pellet diameter: 0.6-20mm

- Feed features: sinking, slow sinking, floating

- Can feed aquatic animals: catfish, carp, tilapia, salmon, squat fish, cod, salmon, tuna, sardines, basa fish, crab, prawns, shrimp and so on.

- Raw materials: animal protein such as fish meal and shrimp meal, vegetable protein such as soybean and algae, animal and vegetable oils such as fish oil and rapeseed oil, energy such as corn and wheat flour, premix such as trace mineral and additives, flavoring agents.

Aqua feed plant is suitable for the processing of raw materials such as protein and fat, which meets the needs of fish for feed. In addition, the types and growth stages of fish are different, and the formula of feed is not exactly the same, but the types of raw materials are not very different. The design and equipment selection of aquatic feed plants vary according to the needs of fish feed products.

Application and type of fish feed plant

A competitive fish feed plant can provide a variety of aquaculture plants with high nutrition, easy to eat, good water resistance of fish feed, to solve the problem of fish eating difficult, poor absorption, slow growth and so on.

floating fish feed mill

Floating fish feed mill adopts the extrusion technology to produce the extruded feed pellets floating on the water surface. The main equipment includes floating fish feed extruder, drying machine, spraying machine and so on. There is usually a more typical floating fish feed production line, of course, the design of the production line and equipment configuration change according to the production needs of the aqua feed plant.

The processing temperature of extruded feed is higher, and the oil content is also higher, which are conducive to the absorption and growth of fish. The floating feed is suitable for fish that often breathe on the water surface and are used to eating on the water surface. The feeders can also clearly see if the fish food needs to be added.

Sinking fish feed plant

The sinking fish feed plant is mainly used to produce benthic fish feed or shrimp feed. The characteristic of the feed is that it will sink in the bottom, and the water resistance requirement is relatively high. If farmed fish prefer to live on the bottom, then the sinking fish feed can promote its feeding and growth.

The production of sinking fish feed can use RICHI SZLH pelletizing machine or extruder machine, and the required sinking fish feed pellets can be produced through the appropriate formula and process. Of course, in the pelletizing of sinking fish feed, the cost of the pelletizing machine is less. However, in the production of aquatic feed, the expansion machine is more widely used. We choose profitable equipment according to our actual situation.

Floating and sinking aquatic feed plants

The aquatic feed plant will generally be a composite line, which can produce both sinking fish feed and floating fish feed. For example, floating fish and shrimp feed mill, the pelletizing section of its composite production line will most likely be equipped with two kinds of equipment, floating fish feed extruder machine and shrimp feed pellet machine. The crushing section, the drying and cooling section will also be adjusted according to the needs of feed production.

This composite production line has a wide range of applications and a high utilization rate throughout the year. Some sections of the production line are shared, which can save fish feed mill plant cost. Therefore, for want to produce a variety of types of fish feed mills, it has a high cost performance.

What are the fish feed mills that RICHI can build?

RICHI can build 0.5-60T/H fish feed mill plant for customers all over the world, and can also customize aquatic feed mill to meet individual needs for customers.

0.3-1T/H fish feed processing line

1.5-2T/H floating fish feed plant

3-4T/H automatic fish feed making machine

4-5T/H fish feed plant

6-7T/H floating fish feed mill

8-10T/H fish feed production plant

10-12T/H shrimp feed mill

12-14T/H shrimp feed pellet mill

16-20T/H fish food production line

20-30T/H fish feed mill plant

30-40T/H aquatic feed mill

40-60T/H aqua feed plant

How to build a fish feed mill plant?

The choice of fish feed pellet mill and equipment needs to be determined by the following comprehensive considerations:

Feeding needs or feed sales needs

We have built a lot of fish feed plants, most of the customers produce fish feed for sale, there are a small number of customers produce fish feed for their own use. For either purpose, we need to determine the type, size and demand of fish feed we want to produce, so that we can choose the right fish feed pellet plant solution and equipment.

Feed plant area or plant space size

This is related to the solution design of the production line, and different solution designs will have different sizes. The new factory can be planned according to the solution design. If it is the original plant, we can design according to the size of the plant.

Budget your investment

The amount of investment is the key to consider, because the main purpose of building a feed mill is also profit. We need to choose the small fish feed mill that can quickly return the medium and large fish feed mill plant cost with high long-term income within our affordability. Because the size of the feed mill is not the same, the cost of the fish feed machine, the cost of the steel frame, and the installation cost are also very different.

Original owned industry and local conditions for plant construction

Many of the customers are the owners of fishing companies or feed mills, and they will expand or upgrade their businesses. A fish feed pellet mill full of opportunities is a good project. The construction of fish feed plant also needs to consider the local power, water sources, government support, and the development of aquaculture.

What are RICHI Fish Feed mill plant solutions?

We have standard fish feed mill solutions and can also customize solutions according to customer’s needs, budget, plant size and local conditions.

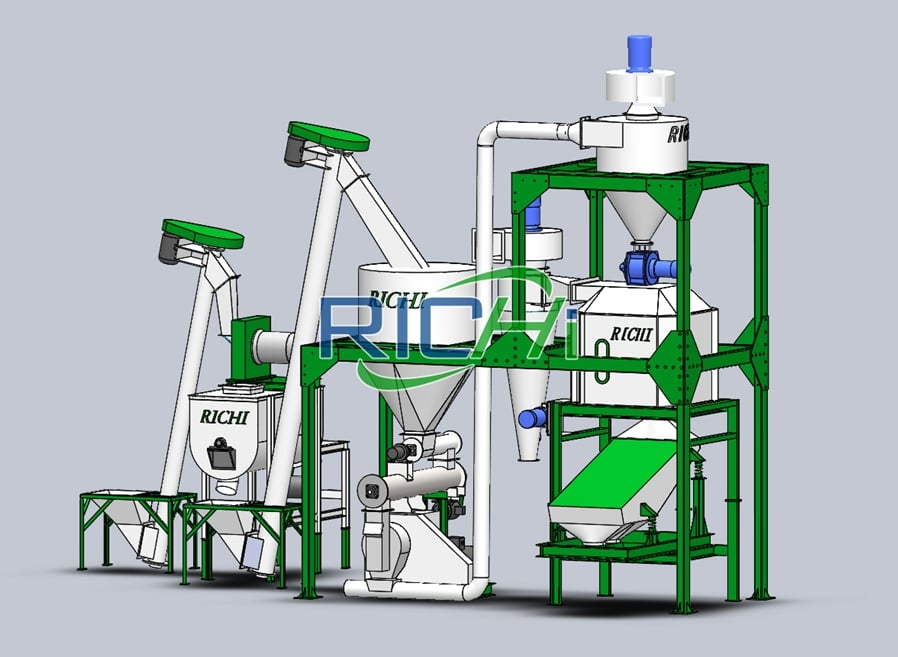

Small floating fish feed mill

- Capacity: 0.5T/H

- Production process: grinding – mixing – extruding – drying – spraying – cooling – packaging

- Features: Low budget, small footprint, to meet the needs of small production

Floating fish feed plant

- Capacity: 1-2T/H

- Production process: crushing – mixing – puffing – drying – spraying – cooling – packaging

- Features: Complete section, dust-proof working environment, relatively low budget

Automatic shrimp feed pellet mill

- Capacity: 2.5-5T/H

- Production process: raw material reception – crushing – automatic batching – mixing – secondary crushing – secondary mixing – granulation – post curing – cooling – screening – packaging

- Features: Automatic batching system improves batching accuracy and feed pellet quality, reduce workers’ wages.

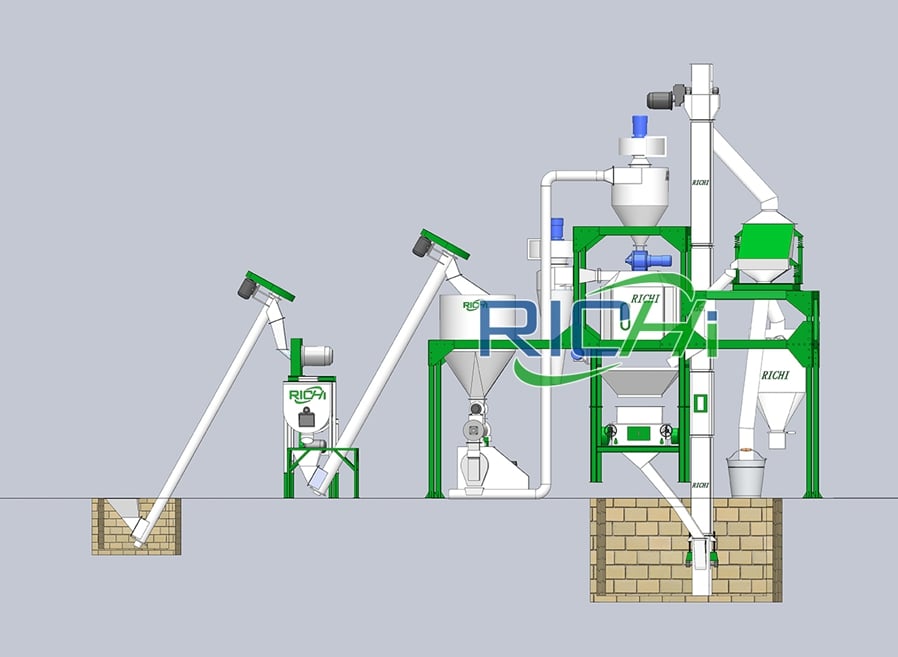

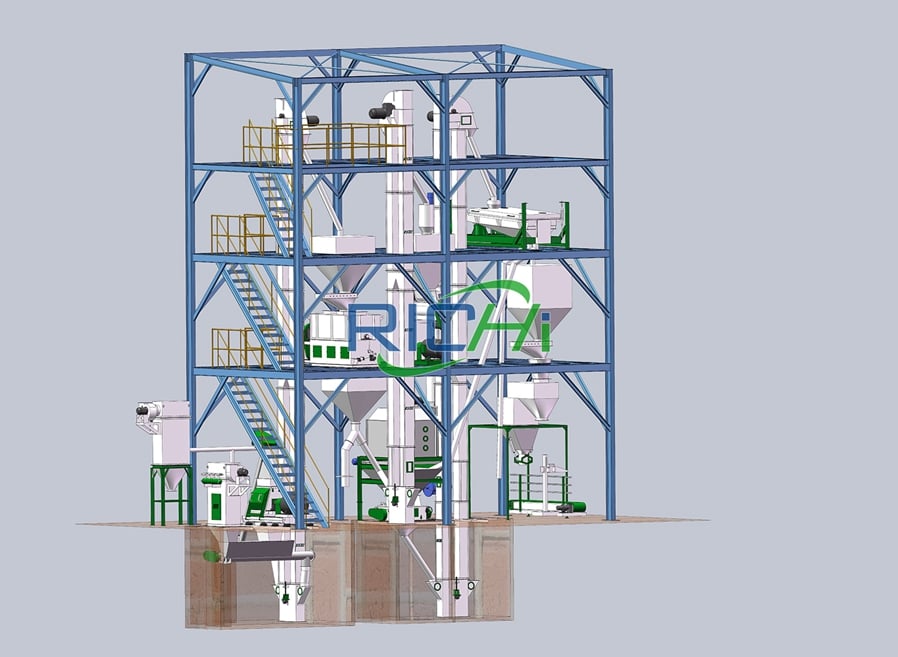

High-grade floating fish feed mill

- Capacity: 5T/H

- Production process: raw material receiving – grinding – automatic batching – ultrafine grinding – mixing – extruding – drying – spraying – cooling – packaging

- Features: This is a standard medium sized floating fish feed line that customers can use directly, saving customization time and additional costs.

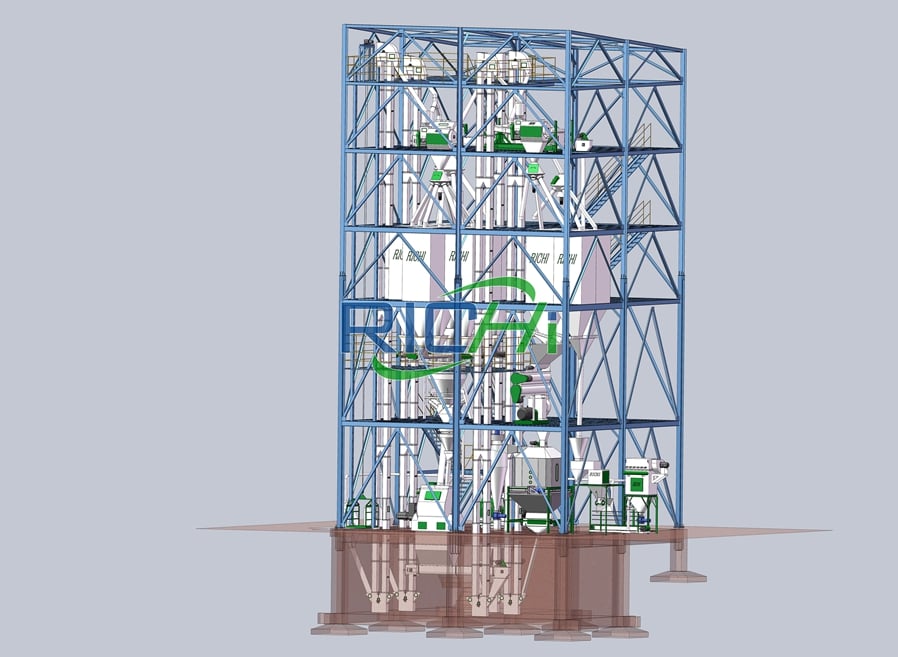

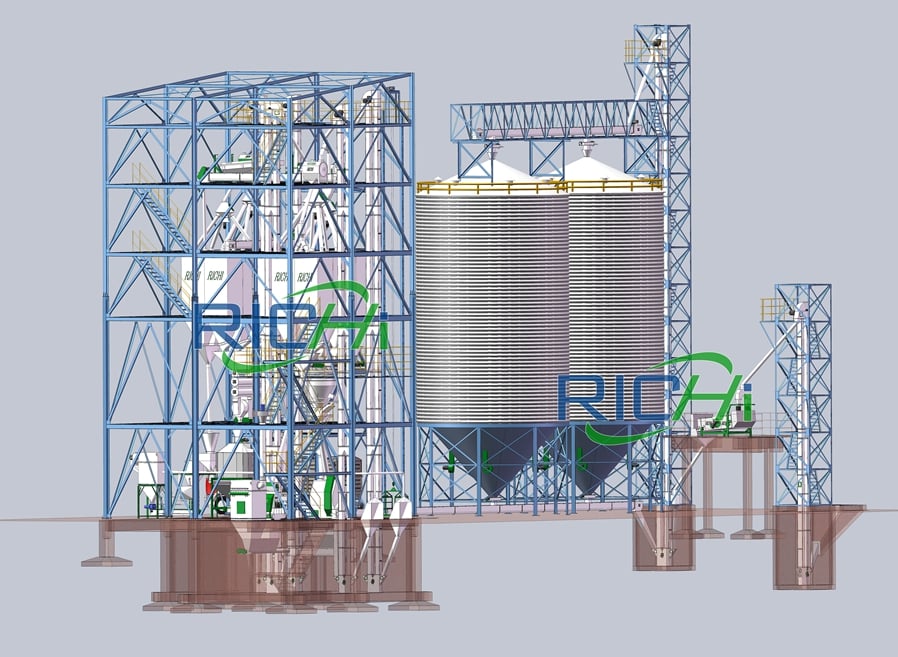

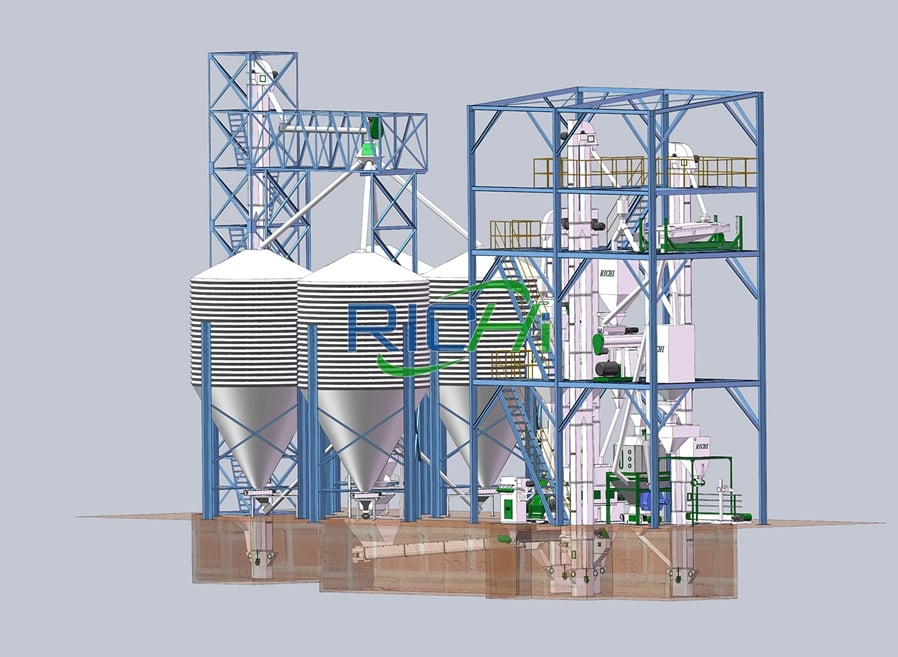

Large fish feed mill plant with silos

- Capacity: 20T/H

- Production process: raw material storage – receiving – crushing – mixing – micro-crushing – mixing – extruding – drying – spraying – cooling – packaging

- Features: Silos can store a large number of raw materials in advance, avoid rising prices when raw materials are scarce, and ensure the continuous production of fish feed factories.

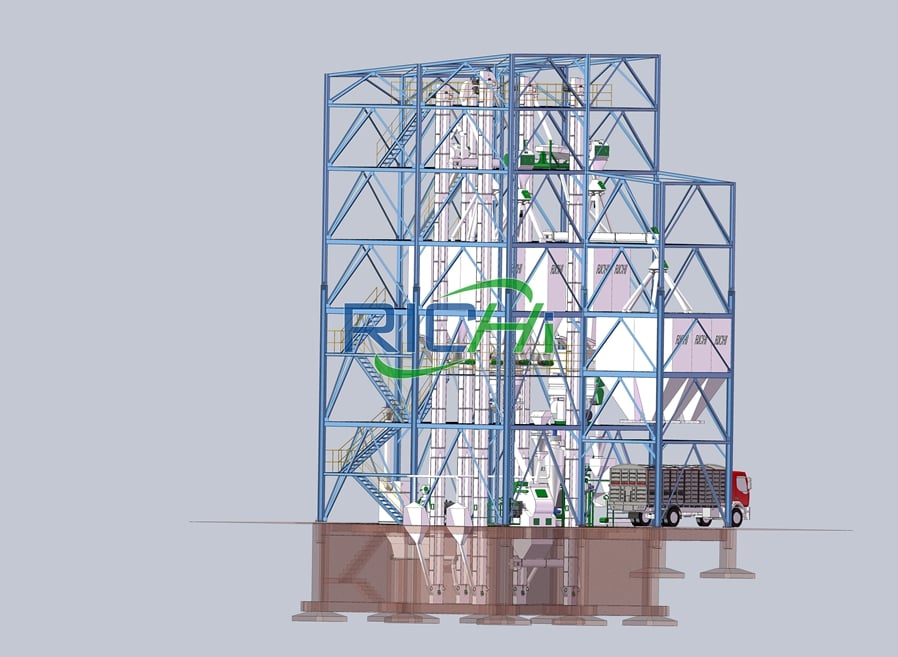

PLC fish feed production line

- Capacity: 10T/H

- Production process: PLC batching – grinding – mixing – micro-grinding – mixing – extruding – drying – spraying – cooling – packaging

- Features: PLC batching system is independent of the production line, improving batching accuracy, saving the cost of steel frame, and also save labor costs.

Manual shrimp and floating fish feed production line

- Capacity: 5T/H shrimp feed and 2T/H floating fish feed

- Production process: raw material mixing – grinding – secondary grinding – secondary mixing – granulation/expansion – post curing & cooling/drying & spraying & cooling – screening – packaging

- Features: The line uses manual batching to save money. The aquatic feed mill plant can produce two types of sinking shrimp feed pellet and floating fish extruded feed, with wide application range and high flexibility.

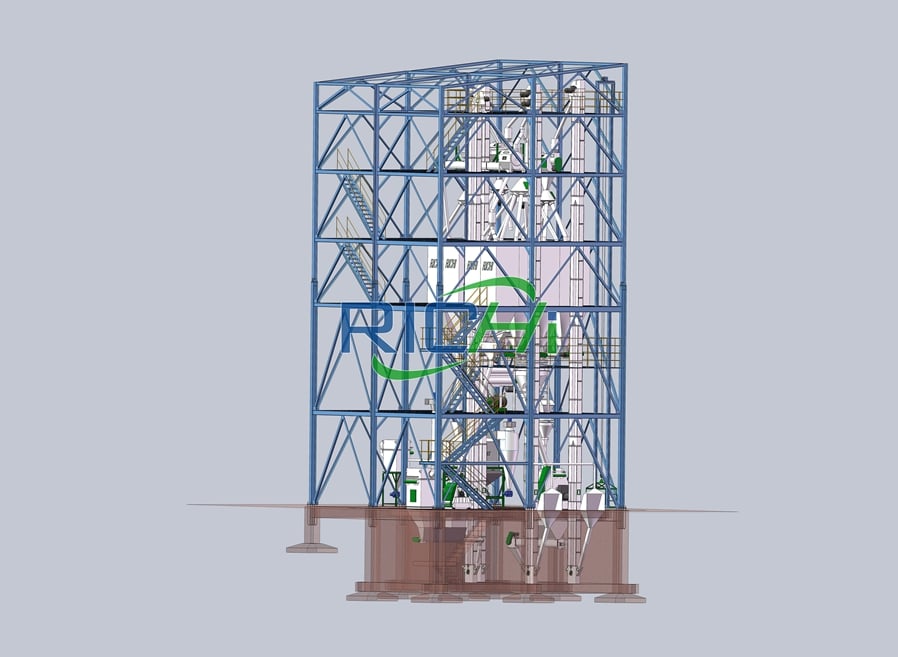

Fully automatic shrimp and fish feed pellet mill

- Capacity: 2.5-5T/H shrimp feed and 8-12T/H sinking fish feed

- Production process: raw material reception – grinding – automatic batching – mixing – grinding/superfine grinding – mixing – granulation – post-curing – cooling – screening – packaging

- Features: The shrimp feed crushing at the secondary crushing stage is specially equipped with a ultrafine grinder to improve the crushing degree of shrimp feed and ultimately improve the quality of shrimp feed.

main equipment and price of fish feed plant

RICHI provides high quality and efficient production equipment for aquatic feed mill.

Fish feed Crusher

Price: $5,000-$35,000

For the coarse crushing section of fish and shrimp feed, the raw materials are crushed coarsely.

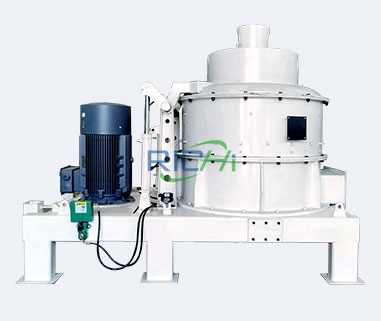

Ultrafine grinder

Price: $30,000-$70,000

Used for ultrafine crushing of shrimp feed or high-grade fish feed, crushing raw materials to 80 mesh. Produce more digestible, good palatability aquatic feed.

Fish feed mixer

Price: $2,500-$40,000

The mixing of different raw materials after grinding is conducive to the production of nutrient-rich and uniform texture of feed pellets.

Price: $10,000-$100,000

In the production of sinking fish and shrimp feed, it has the advantages of high yield, affordable price and high water resistance.

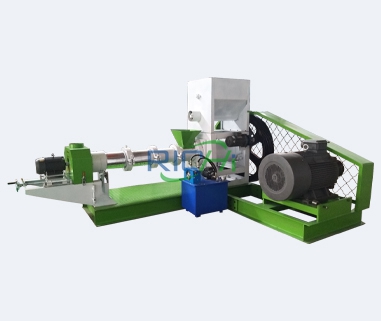

Floating fish feed single screw extruder

Price: $3,000-$40,000

RICHI can provide customers with 150kg/h-4t/h dry and wet fish feed extruder, which is convenient for customers’ diversified needs and choices.

Price: $50,000-$210,000

The output of RICHI twin-screw extruder ranges from 1.5T/H to 12T/H, suitable for high-grade floating fish feed production.

Extruded pellet dryer

Price: $100,000-$220,000

The extruded pellets just out of the extruder are dried first, which is conducive to the oil spraying of the extruded feed. At the same time, the further maturing of feed pellets and the improvement of pellet quality are conducive to the absorption and feeding of fish.

Fish feed pellet cooler

Price: $4,000-$20,000

The feed pellets are quickly cooled to room temperature to prevent pulverization and deformation of the feed pellets. In addition, cooled feed pellets are easier to pack and store.

There are also high square screen, screening machine, packaging machine and other equipment, electric control cabinet, grease adding system, air compressor, steam supply system, electric hoist, conveying system and so on. Contact us for a complete price list of fish feed mill equipment.

Global case of fish feed plant

RICHI fish feed milling machines have been sold to the world, and we have built hundreds of fish feed mills in India, Nigeria, Malaysia, Canada, the United States, the Philippines, South Africa and other countries.

120-150kg/h floating fish feed production line

- Country: Malaysia

- Date: May 23, 2024

- Fish feed mill plant cost: $10,000-$15,000

floating fish feed mill

- Country: Uzbekistan

- Date: September 12, 2018

- Fish feed mill plant cost: $80,000 – $100,000

5-6t/h aqua feed plant

- Country: Russia

- Date: November 16, 2021

- Fish feed mill plant cost: $900,000 – $1 million

1-2t/h fish feed production business plan

- Country: Russia

- Date: July 3, 2013

- Fish feed mill plant cost: $150,000 to $200,000

0.5-1T/H fish feed production plant

- Country: Nigeria

- Date: April 1, 2022

- Guide price: $50,000

3-5t/h fish feed mill plant

- Country: Kyrgyzstan

- Date: August 17, 2022

- Fish feed mill plant cost: $250,000

RICHI MACHINERY

WHY CHOOSE US?

Henan RICHI Machinery Co., Ltd. has been operating for nearly 30 years, and has won the trust and favor of customers.

RICHI Strength

We have first-class pellet machinery production workshop, quality products, professional team, a number of certificates and patents. Committed to providing customers with turnkey services and one-stop solutions.

Rich Experience

We have built animal feed, biomass pellet, etc. production lines for more than 2,000 customers in more than 127 countries and regions around the world.

Cost-Effective

Different customers have different demands. We can customize personalized solutions and equipment for our customers, so that each customer can achieve a profitable project.

4R Service

Reliability, rigorousness, responsiveness and reassurance. Our goal is that every customer is worry-free all the way. You can also choose us with confidence.

500+

500+ device models

1000+

1000+ turnkey projects

127+

127+ countries and regions

2000+

2000+ customers

RICHI MACHINERY

4R SERVICE

Worry-Free All the Way

Reliability

We are committed to providing reliable equipment and services. You can fully rely on RICHI Machinery to ensure the stability and efficiency of your production process.

Responsivene

We promise to maintain a rigorous attitude throughout our entire business. Strive for excellence and meticulousness are the most basic concepts we follow.

Rigorousness

We promise to respond quickly when you need us. No matter what challenge or need you face, our team will provide you with a solution at an efficient pace to ensure your business always runs smoothly.

Reassurance

We promise to provide one-stop service so that you have no worries throughout the process. RICHI Machinery will provide you with full reassurance.