SFSP Feed Hammer Mill

Feed hammer mill is the main equipment of the grinding section of animal feed pellet production line. SFSP series feed hammer mill is suitable for pulverizing raw grain into mash feed. In addition to feed and pellet production industries, it can also be used in pharmaceutical, chemical and other industries.

RICHI MACHINERY

RICHI SFSP Series Feed Hammer Mill

SFSP series feed hammer mill, also known as crushing machine, with high quality, efficiency and capacity, good stability and other unique advantages. As a hammer mill supplier and manufacturer, RICHI Machinery has won the favor of our customers.

- Capacity: 3-25T/H

- Power: 30-160kw

- Made of mash feed size: 0.6-4.0mm, in the feed pellet production line is usually 1-4mm.

- Common raw materials: corn, wheat, soybeans, buckwheat, soybean meal, rapeseed meal, etc.

Basic structure of RICHI SFSP feed hammer mill

Variable Frequency Impeller Feeder

RICHI SFSP feed hammer mill adopts variable frequency impeller feeder, so that the material can enter the crushing chamber more evenly.

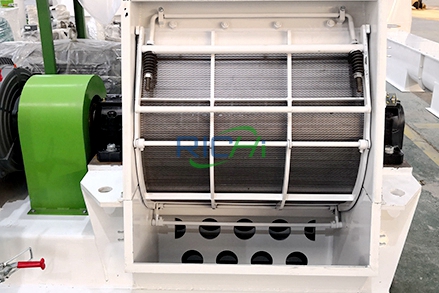

Drop-type crushing chamber

Reasonable water drop crushing chamber structure. After high efficient crushing of the hammer blade head, the materials can achieve secondary grinding, the crushing capacity increased by 25%.

Access door with guide rail

Easy and safe maintenance. There is a lead rail under the maintenance door, which is more convenient to push and pull. There is a limit switch on the maintenance door to protect the safety of production line workers to the greatest extent.

Shell

Steel Shell with high strength and hardness.

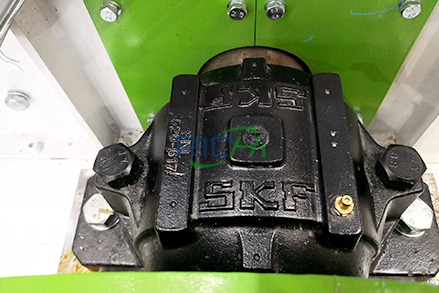

SKF Bearing

Quality and brand accessories.

Siemens motor

Siemens two-stage motor.

Working principle

Feed raw materials enter the impeller feeder, and then enter the drop type crushing chamber through the guide plate, and are crushed by the thump of the high-speed rotating hammer blade and the friction of the sieve plate. Under the action of centrifugal force and air flow, mash feeds pass through the screen hole and are discharged from the discharge port below the machine.

Why can the impeller variable frequency feeder achieve uniform feeding?

Variable frequency impeller feeder is usually connected to conveying equipment or stock bin. The frequency converter controlls the speed, so as to control the flow of materials into the crushing chamber. Our feed ports are designed with a staggered grid to make the materials more even. Impeller variable frequency feeders help the SFSP hammer mill achieve continuous production. No plugging, no idling.

Advantages of RICHI SFSP feed hammer mill

01

High efficiency and configuration, high capacity and low energy consumption

- Hammer blade: quality high carbon steel.

- Hammer blade head: high wear-resistant material – wolfram carbide.

- Sieve mesh: customizable opening size.

- RICHI SFSP animal feed hammer mill in accordance with the consistent standards of RICHI Machinery, the use of high-quality materials and advanced technology. We also have CE and ISO Certification.

- The shaft end air intake system with patented technology increases the output of small-bore materials by more than 20%.

- The energy utilization rate in the crushing process is higher, and the high quality and high configuration hammer mill reduces energy consumption.

02

Long service life, low vibration, low noise

Rotor: high-precision dynamic balance test. At a high speed of 2980 revolutions per minute, so it is very important to ensure that the balance of bearing and spindle in the machine. We have our own dynamic balance instrument. During the production of all hammer mills, high precision dynamic balance tests tbe rotors.. The strict dynamic balance control makes the SFSP animal feed hammer mill more durable, and can also reduce the noise during machine operation and protect the working environment of workers.

Prolong the service life of the hammer blade. The hammer blade can be turned positive and negative, so that both ends of the hammer blade are evenly worn and the service life of the hammer blade is extended. We advise customers to change directions once a week.

03

Excellent detail and humanization designs

- Iron removal function. On the side of the impeller feeder is a magnetic plate, fixed with a high strength magnet, which can remove iron from the raw material entering the feed hammer mill. This function can protect the machine and has a cleaning effect on the feed.

- Save maintenance cost of sieve mesh . When the customer needs a animal feed crusher with high capacity, its crushing chamber will also be larger. We will divide the large crushing chamber into two. Then if a screen is damaged enough to need replacement, the exchange area can be halved.

- With a guide plate at the feed port, the flow direction of input materials can be more easily matched to the direction of the hammer.

RICHI SFSP Hammer Mill for sale

Specification of SFSP Series Hammer Mill

| Model | SFSP56*40 | SFSP66*60 | SFSP66*80 | SFSP66*100 | SFSP138*30E | SFSP138*40E | |||

| Power(kw) | 30 | 37 | 55 | 75 | 90 | 110 | 132 | 110/132 | 132/160 |

| Capacity(t/h) | 3-5 | 4-6 | 5-8 | 6-9 | 8-10 | 10-13 | 12-16 | 15-20 | 18-25 |

| Rotor Dia.(mm) | 560 | 660 | 660 | 660 | 1380 | 1380 | |||

| Crushing Chamber Width(mm) | 400 | 600 | 800 | 1000 | 300 | 400 | |||

| Rotating Speed(rpm) | 2980 | 2980 | 2980 | 2980 | 1440 | 1440 | |||

| Line Speed of Hammers(m/s) | 88 | 103 | 103 | 103 | 103 | 103 | |||

Applications of SFSP series hammer mill

Animal Feed Hammer Mill

SFSP Series hammer mill for animal feed can be used in the animal feed pellet production lines, or the animal mash feed production line. Such as SFSP hammer mill can also be used as corn grinder for chicken feed.

Aquatic Feed Hammer Mill

SFSP Series hammer mill is also suitable for the fish or shrimp feed pellet production. Suitable for the rough grinding section of aquatic livestock feed raw materials.

Wood Hammer Mill

Suitable for wood pellet production line. Wood hammer mill does not require a impeller feeder and has less motor power, but the sieve mesh needs to be thicker and the crushing chamber needs to be larger.

RICHI SFSP animal feed hammer mill in feed pellet production line

SFSP animal feed hammer mill is in the first section of the feed pellet production line – the crushing section, the crushed materials are mixed, granulated, cooled, and finally formed feed pellets. The feed port of the feed crushing machine is usually connected to the stock bin or screw conveyor. RICHI SFSP hammer mill is usually used with a negative pressure ventilation system, including settling chamber, pulse dust collector, draught fan, anti-wind conveyor. The negative pressure induced air system can assist the discharges of the hammer mill and improve the productivity of the hammer mill.

Because of its high efficiency, high yield, stability, safety, easy to operate and other characteristics, RICHI SFSP animal feed hammer mill has become the first choice for many feed plants and pellet plants. Whether it is the hammer mill for corn and other granular grains, grinding machine, wood hammer mill, wood chipper used for logs, the grass crusher, feed pellet crumbler, or the ultrafine grinder for floating fish feed pellet, we can provide. If you have raw materials that need to be crushed, you can contact us.