Cow Dung Pellet Making Machine

The cow dung pellet making machine will mechanically press the crushed cow manure into cow manure pellets. Processed cow manure pellets can be used as organic fertilizer or fuel. Therefore, the use of cow dung pellet machines can not only help cattle farms process large amounts of manure and bring additional revenue, but also create renewable energy for people. Therefore, the purchase of cow dung manure making machine and the construction of cow dung pellet production line are promising investment project.

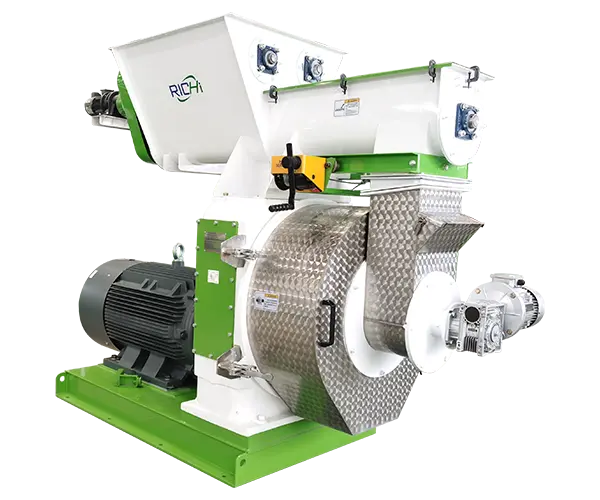

CE ISO Certified RICHI Cow Dung Pellet Making Machine

RICHI cow dung pellet making machine is designed according to the characteristics of cow dung pellet raw materials and granulation process. It has the advantages of high capacity, stable operation, low failure rate, high automation and humanized operation.

Cow manure pellet machine is a ring die biomass pellet machine independently developed by RICHI Machinery, which has passed CE, ISO and other quality certification certificates. In addition, RICHI Machinery has multiple new patent certificates in the design and manufacturing of ring die pellet machine. RICHI is a leader in China’s pellet production equipment industry, mastering the advanced ring die cow dung pellet machine design and manufacturing process.

- Model: MZLH series cow dung pellet making machine

- Output: 1-12 tons of cow dung pellets per hour

- Main motor series: 6P or 8P (Customers can customize according to the raw material formula. Materials that are difficult to mold usually require a motor with low speed and high strength, that is, a motor with high series.)

- Main motor power: 22-280kw

- Finished cow dung pellet diameter: 6-12mm

- Customizable: Yes

- Raw materials: cow dung, cow dung cake, hay, straw, rice husk, rotten silage, coal slime, food residue, etc.

Where can RICHI cow dung pellet machine create value?

The main value of RICHI cow dung pellet machine is to process useless or even harmful cow and cattle waste into cow dung pellets that can be sold or used by oneself. So, where is the most needed cow dung pellet making machine?

Cattle farms and breeding plants

First of all, let’s look at a statistic, a cow excretes up to 60 kilograms a day. Even a small cattle farm with a capacity of only 200 cattle can flood the farm if the manure is not treated. Cow manure from medium and large scale breeding plants is a very urgent problem. If the manure is not handled properly, the cattle farm risks being shut down by the environmental protection agency. Therefore, cattle farms are looking for ways to dispose of cattle manure. In this process, we talked to many cattle farms to come up with solutions to convert cow dung into cow dung pellets using cow dung pellet making machines and their auxiliary equipment. It not only solved the problem of cow dung accumulation, but also created objective benefits for the cattle farms. In addition, the cow dung pellet making machine is not only suitable for cow dung granulation, but also can be used for other livestock farms to produce chicken manure pellets, sheep manure pellets, pig manure pellets, horse manure pellets and so on.

Cow dung organic fertilizer plant

Organic fertilizer plants generally produce a variety of animal manure pellets, the volume of cow manure in reality is relatively large, so cow manure fertilizer pellet machine and cow manure related processing equipment in cow manure organic fertilizer plants is very common.

RICHI cow manure fertilizer pellet machine has a high production capacity, which can meet the production needs of most organic fertilizer plants. What’s more, RICHI Machinery can provide customers with one-stop services, including consulting, equipment selection or customization, machinery design, manufacturing, testing, shipping, installation, worker training and after-sales. Whether you buy a cow manure fertilizer pellet machine for your original organic fertilizer plant or build a new organic fertilizer production line, we can provide the right solution to solve your existing problems. RICHI Machinery has been sold to Greece, Lithuania, Mexico, Thailand, Russia, Uzbekistan, Iceland, Poland, Canada, the United States and so on.

Commercial biomass pellet plant

In biomass pellet plants, cow dung is usually mixed with straw and rice husks for fermentation, crushing, and then using cow dung machine to make cow dung pellet fuel. The structure, function and working principle of the cow manure pellet machine and the straw pellet machine are the same, which can realize the efficient production of biomass fuel pellets. RICHI cow dung machine for biomass pellet plant can not only process cow manure pellets, but also can process compost particles, wool organic fertilizer pellets, straw pellets, rice husk pellets, organic waste pellets, biomass pellets and so on.

In the commercial biomass pellet plant, our cow manure pellet machine can meet the needs of customers with a multi-purpose machine. Besides, we can provide customers with a complete set of mechanical equipment to establish a complete biomass pellet production line. 1-12T/H cow manure pellet machine can be used for 1-60T/H commercial biomass pellet plant.

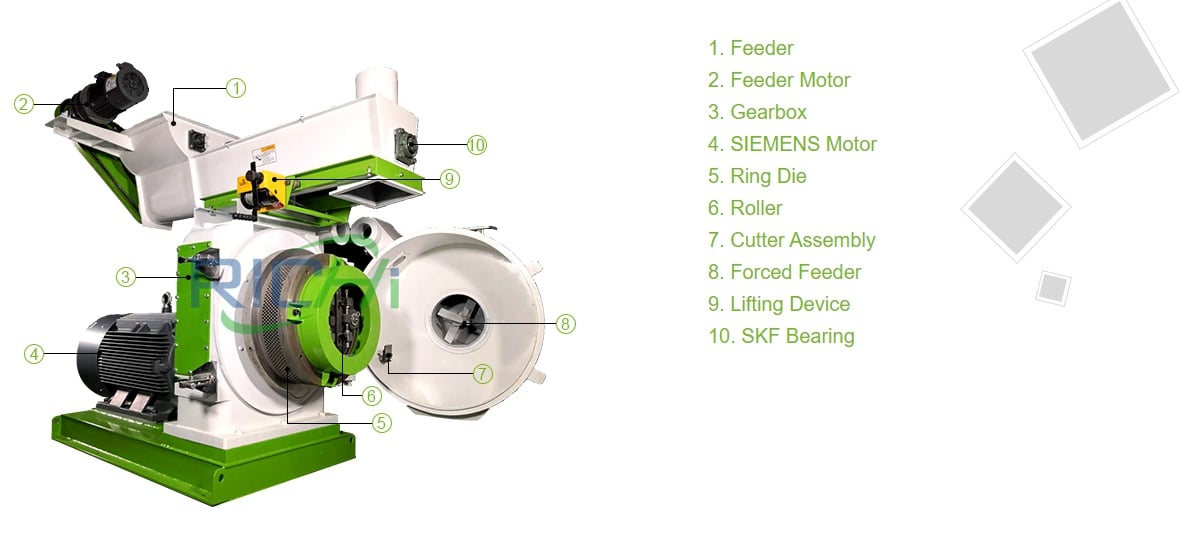

How to convert cow dung powder into manure pellet?

The cow dung pellet making machine can be used to convert cow dung powder into cow dung pellets. In the production process of cow dung pellets, the materials (cow dung powder or a mixture of cow dung and other materials) are usually sent to the stainless steel feeder of the pellet machine through the conveying equipment, and the feeder transfers the material evenly to the chute. The material enters the working area of the pelletizing chamber under the action of the forced-feeder and the feeding scraper. The high density columnar cow manure is extruded from the holes of the ring die by the extrusion of the ring die and the press roller. The cutter will cut the columnar cow dung, and the high-density granular cow dung pellets are completed. This is how the cow dung powder is transformed into cow dung pellets by the cow dung manure making machine.

Detail parameters of RICHI cow dung pellet machine

The material and design of the RICHI MZLH manure pellet machines are roughly the same except for the customized machine requested by the customer. However, different models and capacity of cow dung machines, their power and ring die diameter are not the same. We can choose machines according to our own needs.

MZLH320 cow dung pellet making machine

- Capacity: 1-2T/H

- Main motor power: 22kw

- Ring die diameter: 320mm

- Cow dung pellet diameter: 6-12mm

MZLH350 cow dung pellet machine

- Capacity: 3-4T/H

- Main motor power: 37kw

- Ring die diameter: 350mm

- Cow dung pellet diameter: 6-12mm

MZLH420 cow manure fertilizer pellet machine

- Capacity: 5-6T/H

- Main motor power: 90kw

- Ring die diameter: 420mm

- Cow dung pellet diameter: 6-12mm

MZLH520 cow dung manure making machine

- Capacity: 7-8T/H

- Main motor power: 132kw

- Ring die diameter: 520mm

- Cow dung pellet diameter: 6-12m

MZLH768 horse manure pellet maker

- Capacity: 9-10T/H

- Main motor power: 250kw

- Ring die diameter: 768mm

- Cow dung pellet diameter: 6-12mm

MZLH858 organic fertilizer pellet machine

- Capacity: 10-12T/H

- Main motor power: 280kw

- Ring die diameter: 858mm

- Cow dung pellet diameter: 6-12mm

The above models and parameters will be slightly adjusted according to the actual situation, please contact us for the latest information.

How to use cow dung pellets made by cow dung pellet making machine?

Cow manure pellets can be used as organic fertilizer particles, and can also be used as fuel pellets.

Organic fertilizer pellets

What do farmers do with cow manure pellets? The content of organic matter in cow manure is 14.5%, nitrogen is 0.3%-0.45%, phosphorus is 0.15%-0.25%, and potassium is 0.1%-0.15%. As an organic fertilizer, it is low in nutrients compared to chicken manure and other animal manure. However, cow manure decomposes slowly, which is a late-acting and cold fertilizer. Cow manure pellets made by cow manure fertilizer pellet machine is suitable for use as base fertilizer and can also be mixed with quick-acting fertilizer to produce better results on soil and crops.

Biomass fuel pellets

Cow dung often contains undigested plant residues, and there will also be pastures, straw, and rotting silage mixed with the manure. Therefore, cow dung is usually processed into biomass fuel pellets, which are used in biomass power plants, industrial boilers, home heating, etc. In the production process of cow dung particles, through a series of processes such as fermentation, drying, granulation, cooling, etc., the odor in cow dung is removed, which is an efficient and environmentally friendly renewable energy.

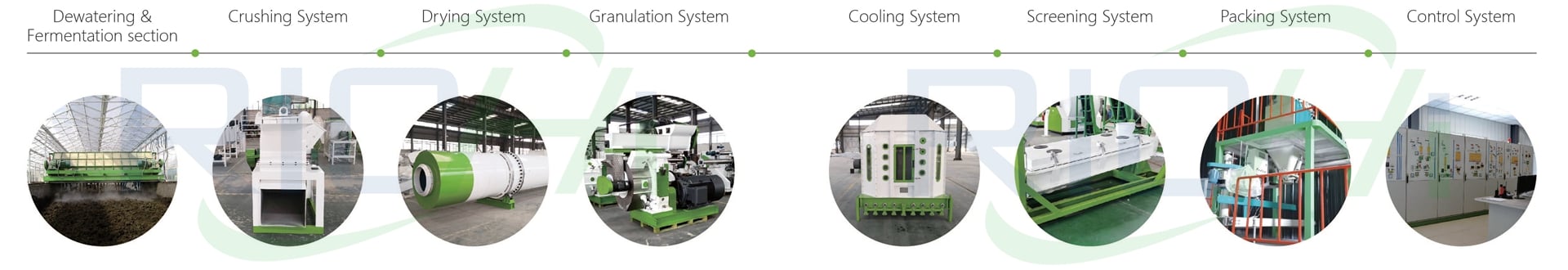

How to make pellets from cow dung?

— Richi Machinery —

Through the cow dung pellet production line, understand the whole process of making a large amount of cow dung into pellets.

- Dewatering & Fermentation section: The first stage of cow dung processing is dehydration and fermentation to eliminate harmful bacteria, insects and odors in cow dung. In the process, straw, rice husks, etc., are usually mixed. A cow dung compost making machine will be used in this section.

- Crushing and drying system: The dehydrated and fermented cow manure is crushed and dried to a water content of 15%-18%. The main equipment used in the system are cow dung crusher machine and cow dung dryer.

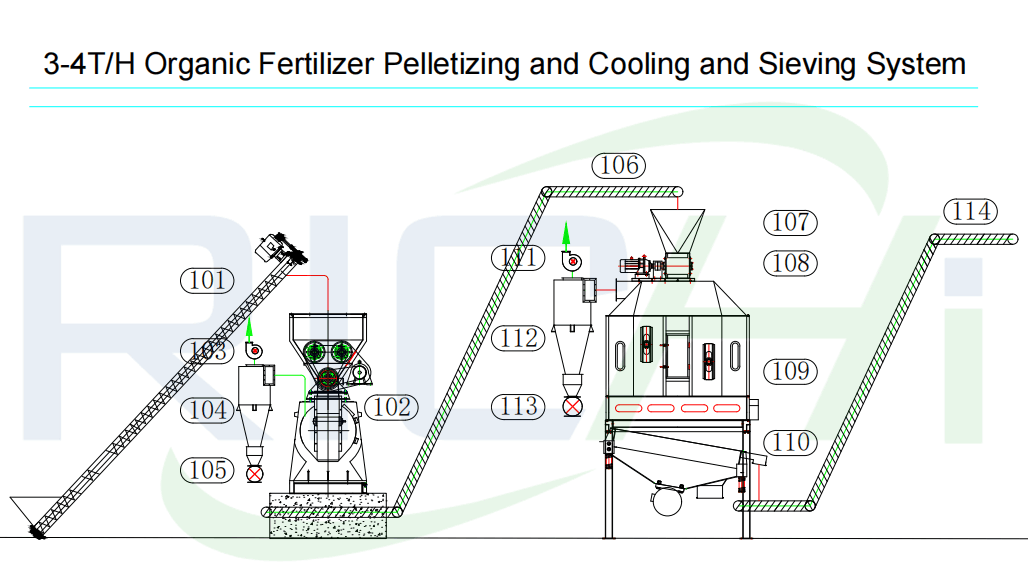

- Granulation and cooling system: the cow dung powder is pressed into 6-12mm cow dung pellets and cooled to about room temperature. The cooling system is generally installed directly below the pelletizing system to reduce the conveying distance of the pellets, thereby reducing the damage of the pellets.

- Screening and packaging system: The formed cow dung pellets are screened to obtain the required size pellets and enter the packing system.

Main cow dung processing machines of cow dung pellet line

The main cow dung processing machines used in the whole production line are cow dung compost making machine, cow dung crusher, cow dung dryer, cow dung manure making machine, pellet cooling machine, screening machine, packing machine, electric control cabinet and so on. RICHI Machinery can provide customers with all of the above cow dung processing machines and design solutions for cow dung pellets production. Contact us soon.

Related case of RICHI cow dung pellet machine

As an experienced exporter of cow dung pellet making machines and animal manure pellet machines, RICHI manure pellet machine has been exported to 128 countries and regions around the world. Here are some examples, if you want to know more, please contact us.

Cow dung pellet production line

- Country: India

- Date: May 17, 2022

- Output: 4-5T/H

- Guide price: $250,000-300,000

Organic fertilizer pellet production line

- Country: Greece

- Date: October 4, 2023

- Output: 3-4T/H

- Guide price: $50,000 – $100,000

Chicken manure pellet machine

- Country: Lithuania

- Date: October 31, 2023

- Model: MZLH320

- Guide price: $20,000 – $30,000

Poultry manure pellet machine and accessories

- Country: Germany

- Date: May 21, 2024

- Model: MZLH350

- Guide price: $30,000 – $40,000

You may also like

Frequently Ask Question

Frequently Ask Question

Click Here to buy now.

Why choose RICHI cow dung pellet making machine?

RICHI cow dung pellet making machine uses high quality materials, reasonable design and advanced production technology.

- All parts in contact with the material, such as the feeder, chute and ring die, are made of stainless steel to prevent corrosion of the machine and extend the service life of the pellet machine.

- Gear box, coupling structure is compact. cow dung machine has small size, stable operation, low noise and high efficiency.

- The machine adopts humanized designs, such as the feeder observation hole, the granulating room cutter observation hole, so that the worker can understand the operation of the machine inside.

- RICHI Machinery is a professional manufacturer of ring die pellet machine, so ring die of cow dung pellet making machine also has the advantages of not easy to crack, large capacity and so on.

- We can customize different capacity and pellet size of cow dung pellet making machine for customers, welcome to consult.

Any Question?

You can ask anything you want to know about Feedback

RICHI MACHINERY

4R SERVICE

Worry-Free All the Way

Reliability

We are committed to providing reliable equipment and services. You can fully rely on RICHI Machinery to ensure the stability and efficiency of your production process.

Responsivene

We promise to maintain a rigorous attitude throughout our entire business. Strive for excellence and meticulousness are the most basic concepts we follow.

Rigorousness

We promise to respond quickly when you need us. No matter what challenge or need you face, our team will provide you with a solution at an efficient pace to ensure your business always runs smoothly.

Reassurance

We promise to provide one-stop service so that you have no worries throughout the process. RICHI Machinery will provide you with full reassurance.