CHICKEN FEED PRODUCTION LINE

Excellent chicken feed production line can produce high quality feed pellets with high yield.

RICHI Chicken Feed Production Line

If you want to build a chicken feed production line, please see RICHI Machinery’s chicken feed production process and equipment to make a choice.

- Raw materials: soya, corn, wheat, other grains, etc.

- Types of chicken: broiler, breeding hens, layer, baby chicken, small chicken, middle chicken, big chicken.

- More animals: Ducks, Geese, Pigs and Other Poultry and Livestock

- Pellet size: 1-12mm (chicken generally choose 1.5-4mm.)

- Capacity: 1-100T/H

Can’t find the chicken feed production line you want?

Contact us to customize for you

Chicken Feed Production Process

The design of chicken feed production process is very important, not only related to the rationality and efficiency of chicken feed pellet production, but also directly related to the size of the customer’s factory, capital investment and output. RICHI Machinery’s customized design of chicken feed production process is unique, so it is also the first choice of many domestic and foreign customers.

The common chicken feed production process is also similar to that of other poultry animal feed pellets. So, there are mainly the following steps, each step will require corresponding chicken feed production equipment to complete, to ensure the smooth production of animal feed pellets.

Chicken Feed Production equipment on each process

Storage, receiving and cleaning of raw materials

Raw materials of chicken feed production line mainly include soya, corn, wheat, and other grains. The storage of raw materials is mainly for chicken feed plant. For animal feed plants with year-round production needs, the use of steel silos are mainly storing these grains. Besides, these steel silos can add ventilation and cooling functions to ensure the good condition of the grain. We can use our own dump trucks to weigh bulk materials, and then unload them into steel silos.

Raw materials receiving is the beginning of chicken feed production process. Chicken feed is formulated, requiring workers to accurately weigh each raw material and place all raw materials separately according to two categories that need to be crushed and do not need to be crushed.

Cleaning of raw materials is the pretreatment section, the purpose is to clean out the impurities and iron-containing substances in the raw grain. Ensure quality of animal feed pellets and normal operation of crush mill.

steel silos

Bulk storage of corn, wheat and other raw grains.

Pulse dust collector

Protect the working environment of workers during the raw material receving process.

Drum type precleaner

Screening of large impurities in raw grain on cleaning system.

Crushing, Batching and mixing

The cleaned raw materials are crushed to a certain fineness according to the formula requirements by feed hammer mill, and then transported to the next section. The function of feed hammer mill is mainly crushing various raw grains, grains, feed and various roughage. The purpose of feed hammer mill is to increase feed surface area and adjust grain size. Increased surface area improves palatability, it is easy to come into contact with digestive fluids in the digestive tract. It is beneficial to improve digestibility and better absorb feed nutrients. The crushed raw materials are more suitable for pressing feed pellets.

The main function of batching and mixing is to accurately weigh the feed according to the requirements of the feed formula. The way of weighing can be done by PLC program. Complete the process of unloading, weighing and mixing in the shortest possible time.

Feed hammer mill

Advanced water-drop crushing chamber design.

Rotary distributor

Round platform structure, no residue, high precision.

animal feed mixer

SKF bearing, high uniformity, high efficiency.

Pelletizing

Pelletizing is the core process of complete chicken feed production line, it is press the powder feed materials into pellets. The chicken feed pellet machine can press powder materials such as wheat, bran, maize, soybean meal, peanut meal, cottonseed meal, etc.

Feed pellets have comprehensive nutrition and strong stability, which can improve the digestibility of animals to feed, reduce picky eating , be economical, avoid automatic classification of feed ingredients, reduce environmental pollution, and kill bacteria in animal feed after aging. Convenient storage and transportation. Aquatic feed pellets are not easy to break up in water, not easy to pollute water, easy to digest and absorb.

RICHI chicken feed pellet machines for sale

| Model | Output (t/h) | Main motor power (kw) | Finished pellet diameter (mm) |

|---|---|---|---|

| SZLH250 | 1~2 | 22 | 2~12 |

| SZLH320 | 3~4 | 37 | 2~12 |

| SZLH350 | 5~7 | 55 | 2~12 |

| SZLH420 | 8~12 | 110 | 2~12 |

| SZLH508 | 10~18 | 160 | 2~12 |

| SZLH558 | 15~25 | 180/200 | 2~12 |

| SZLH678 | 20~30 | 220/250 | 2~12 |

| SZLH768 | 25~40 | 250/280 | 2~12 |

| SZLH858 | 28~45 | 315/355 | 2~12 |

Advantages of RICHI chicken feed pellet machine

01 Stainless steel ring die

Our clamp is forged, which makes it stronger and more durable. The ring die compression ratio of livestock feed is about 1:3.5-1:1.13. The compression ratio is the ratio of the effective thickness of the ring die hole to the minimum diameter of the ring die hole, which is an index reflecting the extrusion strength of feed pellet. The larger the compression ratio, the stronger the extruded feed pellet.

02 Single axis paddle type conditioner

The blades are forged, cut directly from the steel plate. More wear resistant. Many on the market are cast, not strong and durable. The arrangement of the blades is arranged in accordance with a certain angle. The feeding speed is uniform to ensure the full mixing of materials and steam, and improve the quality control effect.

03 Larger size conditioning for chicken feed pellet machine

Good conditioning can greatly increase chicken feed pellet yield, reduce energy consumption and improve feed pellet quality. The “three elements” of conditioning are temperature, moisture and time. Chicken feed: 75-85℃. The usual mixed feed, especially the low-protein feed, has a starch content of more than 50%, and the moisture after conditioning can reach 15-17%. For high-fiber or high-protein feeds, the water content is limited to 13-14%. Livestock feed conditioning time is greater than or equal to 15s-40s. Larger size conditioning for chicken feed pellet making machine:

- SZLH 250: Length 1800mm* Diameter 273mm

- SZLH 320: Length 2000mm* Diameter 320mm

- SZLH 350: Length 2440mm* Diameter 350mm

- SZLH 420: Length 3000mm* Diameter 420mm

cooling, crumbling and screening

The feed pellet temperature from chicken feed pellet making machine is 80°C, and the moisture is 15%-16%. It is not suitable for packaging. The size of chicken feed pellets requires different cooling time to ensure the cooling effect, the larger pellets need to cool the longer. The adjustment of the cooling time is completed by the material level device, adjust the height of material level device can adjust the cooling time. Chicken feed pellets in the cooling bin after the cooling time are discharged layer by layer, and feed pellets that need to be crushed into the pellet crumbler.

The pellet crumbler is a special equipment for crushing large feed pellets (about φ3mm-6mm) into small feed pellets (about φ1.6mm-2.5mm). The size of crushed pellets can be adjusted by adjusting the gap of the press roller.

SFJH series rotary screener can grade feed pellets for finished products packaging or recycling.

Feed pellet cooler

Large production capacity, high degree of automation.

Crumbler

Increasing chicken feed production line capacity of small feed pellets (about 1 mm).

SFJH series rotary screener

Screen out qualified chicken feed pellets and recycle large pellets or powdered feed.

packing and converying on chicken feed production process

automatic Packing system

Automatic packing machine, sewing machine, belt conveyor.

Bucket Elevator

Common conveying equipment on feed pellet production line.

Scraper conveyor

No need to dig the pit, the plant height requirement is lower.

Customized chicken feed production process and quality equipment

Building a win-win chicken feed production line

Why build a Chicken Feed pellet Production line?

Feed pellets have comprehensive nutrition and strong stability, which can improve the digestibility of animals to feed, reduce picky eating , be economical, avoid automatic classification of feed ingredients, reduce environmental pollution, and kill bacteria in animal feed after aging. Convenient storage and transportation. Aquatic feed pellets are not easy to break up in water, not easy to pollute water, easy to digest and absorb.

A large chicken farm with its own chicken feed production line will never be in a feed crisis. So, for large chicken farms, adequate feed is very important. If the chicken feed pellets are not enough, it means selling the chickens in advance or not getting enough eggs. This is not a good news for chicken farms. So, some large chicken farms choose chicken feed pellet making machine for making chicken feed pellets by yourself. What’s more, some chicken farms need to explore new opportunities and expand their businesses. Then, choosing the chicken feed business such as chicken feed production line in the industrial chain has become an optimal choice for these chicken farms.

How to choose chicken feed pellet production lines?

Large and excellent chicken farms are very specialized in raising and are very successful in selecting chicken feed. However, it is not professional to choose feed pellet machinery. Today we are going to offer some professional knowledge of choosing chicken feed pellet making machines. The following contents come from RICHI Machinery. RICHI Machinery is a professional animal feed pellet machinery manufacturer, which has 29 years of experience.

Chicken feed production line price

$10,000-$1,000,000.

According to customers’ needs, sites, local food seasonality and other conditions, RHICI Machinery will customize the most cost-effective program. RICHI Machinery is committed to providing one-stop service for animal feed pellet production. And RICHI Machinery has always been the goal is to let every customer worry about the production of animal feed pellets, to solve the practical difficulties of customers in animal pellet production.

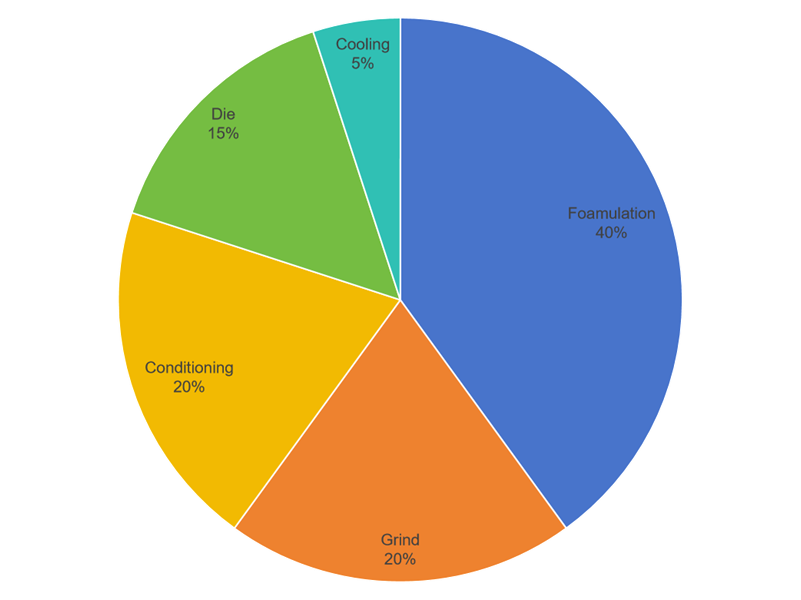

factors affecting quality

- Chicken feed formula accounts for 40%;

- Grind accounts for 20%;

- Conditioning accounts for 20%;

- Die accounts for 15%;

- Cooling accounts for 5%.

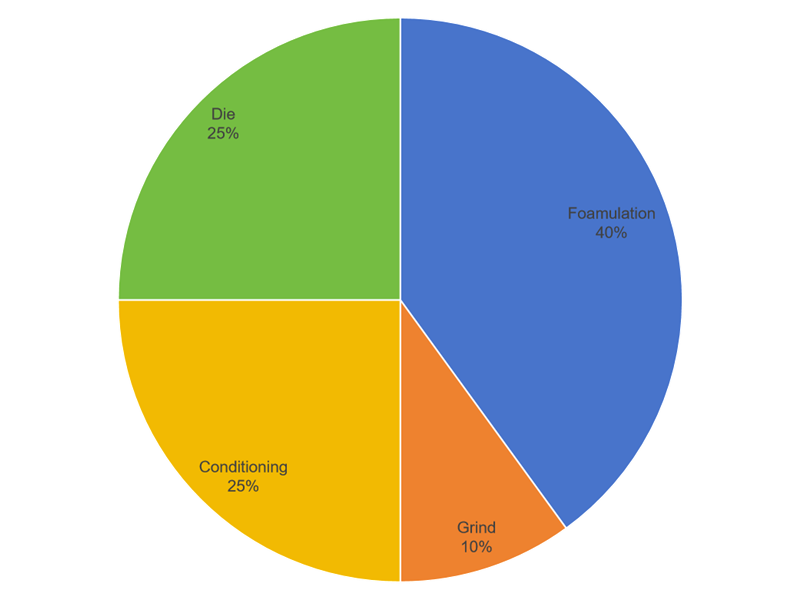

factors affecting capacity

- Chicken feed formula accounts for 40%;

- Grind accounts for 10%;

- Conditioning accounts for 25%;

- Die accounts for 25%.

Ready-made chicken feed formula from RICHI Machinery

The chicken feed formula obtained after many tests has been well received by customers. Soybean meal 53% ; Cotton seed meal 18%; Rape-seed cake 4.1% ; Maize protein meal 8%; DDGS(distillers dried grains with soluble) 4%; Calcium bicarbonate 4% ; Stone powder 4%, etc.

For the formula of chicken feed pellet, RICHI Machinery has tried many times to find the optimal solution. If you want to know more, you can contact us to get it. In the manufacturing of animal feed pellet machinery, RICHI Machinery has optimized the above factors. To ensure the production quality and capacity of feed pellets.

Successful cases

RICHI Machinery specializes in the manufacture and export of feed pellet complete sets of projects, can provide customers with barley, maize, soybean meal, cotton seed meal, rape-seed cake, and other raw materials of feed pellet complete equipment. RICHI not only has excellent animal feed pellet making machine and excellent solution design, but also has thoughtful and perfect pre-sales and after-sales technical services. Our company have built a strong team of technical engineers to solve a series of problems in the process of feed pellet production line construction projects. These problems include project consulting, site investigation, sample analysis, program design, installation and commissioning, guidance and maintenance. RICHI Machinery is committed to ensuring that all links connect with customers in place and timely solve customer needs.

Founded in 1995, RICHI Machinery exports to 127 countries. Years of experience accumulation, RHICI Machinery has also had a lot of successful customer cases.

3-5T/H chicken feed pellet production line In Uzbekistan

The customer upgraded the original chicken feed pellet production line in order to improve production efficiency and profitability. The project started in February 2018 and took a year to complete successfully. The professional team of RICHI Machinery completed the installation and testing in only ten days. During the process encountered electrical and other problems, we overcome and solve. So the customer is very happy.

10T/h chicken feed pellet plant project in Fergana, Uzbekistan

The project has been completed and put into operation in May 2020. This chicken feed pellet plant project uses corn, soybean meal and other common chicken feed raw materials. RICHI Machinery customized 8 5-7t/h chicken feed pellet production solutions. RICHI Machinery customized 8 chicken feed pellet production solutions with 5-7 ton per hour according to the needs of customers. Later, the customer’s production requirements for the chicken feed pellet machine increased. RICHI Machinery’s engineering team has re-customized 22 chicken feed pellet production solutions with 10t/h. The final plan was successfully implemented. Finally, The customer is very satisfied.