CATTLE FEED PELLET MACHINE

Excellent cattle feed pellet Machine can produce high quality Containing Grass feed pellets with high yield.

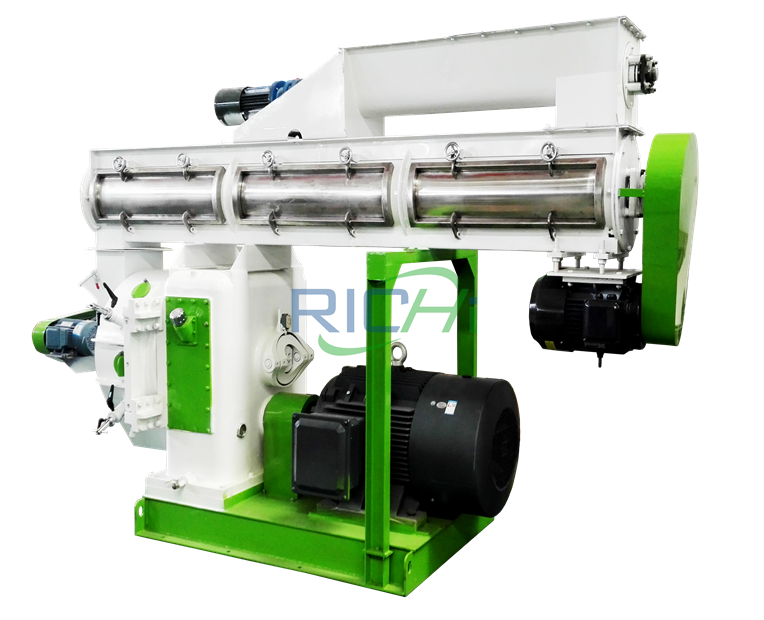

RICHI Cattle Feed pellet machine Price

Cattle feed pellet machine can process raw materials containing grass such as alfalfa into feed pellets. So it is suitable for cows, sheep, camels, rabbits and so on.

- Cattle feed pellet machine price: $20,000-$100,000

- Capacity: 1-40T/H

- Final Pellet Size: 2-12mm (Cattle feed pellets are most commonly 5-8mm.)

- Features: Forced feeder

Why Use Pellet making Machine for cattle Feed?

Widely applicable-Especially friendly for light grass meal

- Pellet making machine for cattle feed is the main machinery of the pelleting section and the core equipment of a ruminant animal feed pellet production line. Besides, the capacity of a cattle feed pellet plant is also determined by the cattle feed pellet making machine.

- Widely applicable. Corn flour, wheat flour, grass flour, wood chips and other powdered grains and biomass are the raw materials of cattle feed pellet making machine. Especially, very friendly for light feed, such as grass meal, straw meal.

RICHI Cattle Feed Pellet Machines for Different Cattle Pellets

- Calves and young cow: 5-6mm

- Breeding cattle: 6-7mm.

- Dairy cattle, Racing cattle: 6-8mm.

- Cattle and cows: 4-12mm.

The size of feed pellets can be achieved by replacing the ring die of cattle feed pellet machine. Therefore, the size of cattle feed pellets can also be customized.

Advantages of cattle feed pellets

- Cattle feed pellets can improve feed digestibility and generally increase feed conversion by 10%. And then high temperature and high pressure in the granulation process are conducive to the elimination of bacteria in the feed and the health of animals.

- In order to meet the needs of feed nutrients at different growth stages of livestock, the feed formula will also change. However, feed pellets make it easier for animals to accept changes in feed formulation. So, avoiding picky eating and reducing feed material waste.

- Cattle feed pellets avoid grading of feed during packaging, transportation and feeding. And feed pellets have good fluidity and will not arch during production, storage and feeding.

1-40T/H Customization with high quality and high efficiency

Contact Us for RICHI Cattle Feed Pellet Machines

RICHI Cattle Feed Pellet Machines For Sale

In order to meet the needs of customers, RICHI Machinery offers a variety of models of cattle feed pellet making machines. So, each customer can choose according to their own capacity, feed pellet size and quality, as well as local conditions. If you need anything else, you can also contact us. Tailor-made for each customer is what we have always done.

Technical Parameters of Multiple Models

| Model | Capacity(T/H) | Main Motor Power(kw) | Feeder Motor Power(kw) | Conditioner Power(kw) | Dia.of Ring Die(mm) | Final Pellet(mm) |

| SZLH250 | 1-2 | 22 | 0.75 | 1.5 | 250 | 2-12 |

| SZLH320 | 3-4 | 37 | 1.5 | 2.2 | 320 | 2-12 |

| SZLH350 | 5-7 | 55 | 1.5 | 3 | 350 | 2-12 |

| SZLH420 | 8-12 | 110 | 1.5 | 7.5 | 420 | 2-12 |

| SZLH508 | 10-18 | 160 | 2.2 | 11 | 508 | 2-12 |

| SZLH558 | 15-25 | 180/200 | 2.2 | 11 | 558 | 2-12 |

| SZLH558D | 14-22 | 160/180/200 | 1.5 | 7.5 | 558 | 2-18 |

| SZLH678 | 20-30 | 220/250 | 2.2 | 11 | 678 | 2-12 |

| SZLH678D | 15-25 | 200/220/250 | 2.2 | 11 | 673 | 2-18 |

| SZLH768 | 25-40 | 280/315 | 2.2 | 11 | 768 | 2-12 |

| SLZH858 | 25-42 | 280/315 | 2.2 | 15 | 858 | 2-18 |

Characteristics of RICHI Pellet making Machine for Cattle feeds

The function is to process the prepared and mixed mash feed into feed pellets that ruminant animals such as cattle and sheep can eat. Granulation processes of cattle feed pellet machine mainly include steam modulation and mechanical pressing.

Adding A Forced Feeder

Cattle, like sheep and camels, are ruminants, and their main diet is straw plants. However, the specific economic value of ruminants need to eat some additional artificially formulated concentrate feed, so that they can produce more meat and milk.Compared with chicken, duck and aquatic animal feed, ruminant feed requires the addition of grass raw materials.

Grass feed is relatively lighter and not easy to feed, pellet making machine for cattle feed is specially equipped with a forced feeder to ensure the uniformity of the feed and improve the pelleting yield.

Containing Grass Materials

The raw material formula has the greatest influence on the quality of feed pellets, accounting for about 40%. The effect on capacity is the same. What’s more, the raw material for cattle feed pellets contains grasses. Then the proportion of grass and grain energy will directly affect the output and quality of cattle feed pellets. As a cattle feed pellet making machine manufacturer, we need to adjust the optimal ratio of raw materials to balance the yield and quality of cattle feed pellets. In addition, if the herders give calves, bulls and cows have different nutritional needs, they also need feed pellet factories to meet them.

RICHI Machinery provides you with production output and quality comparison for different proportions of raw materials. Please contact us to get it.

Single-layer Conditioner

Cattle feed pellet making machine is prepared with a single-layer conditioner. A thermometer is installed at the outlet of the conditioner of cattle feed pellet machine. The temperature at which cattle feed enters the pelleting chamber needs to be controlled at 80°C. There is a valve at the inlet of cattle feed pellet machine conditioner. When the temperature is high, turn down the valve. When the temperature is low, open the valve wider.

The influence of conditioning on feed pellet quality is about 20%. Good conditioning can increase powder moisture, rise the temperature, soften the material , improve the quality of the pellet output, and extend the service life of the dies and ring roll.

Working Principle of RICHI Cattle Feed Pellet Machine

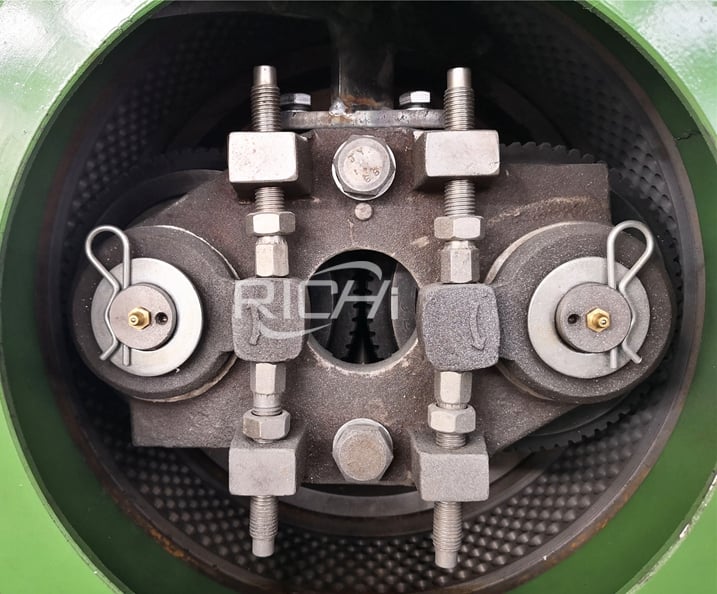

The crushed, prepared, mixed feed materials are fed into the conditioner by a variable frequency feeder. The feed materials contact and fuse with steam in the conditioner. After the feed materials are modulated to a certain temperature and moisture, they enter into the ring mold of cattle feed pellet making machine. Under the strong extrusion of the ring die and the press roller, and under the pressed by a forced feeder, the feed pellets are formed, and then cut into the desired length by the cutter.

Structure of RICHI Cattle Feed making Machine

Pellet making machine for cattle feed is a ring die pellet machine. It is mainly composed of gear box, Siemens motor, stainless steel granulating chamber, conditioner, frequency control feeder with anti-caking device and forced feeder, roll lifting device.

Stainless Steel Pelletizing Chamber

Including press roll assembly, ring die, cutter, scraper, basin, feed chute, manual feed port, by-pass handle.

Gear Box

Gear box includes main shaft, empty shaft, gear shaft, 5 bearings, big gear, safety pin assembly, etc.

Siemens Motor

Main motor is used for coupling and gear reduction. And we all use Siemens motors with high quality.

Conditioner

Conditioner can satisfy ruminant feed pellets. On the cattle feed pellet production line, water vapor from the boiler enters the single-layer conditioner. It has the function of sterilization, curing and increasing yield.

Variable Frequency Feeder

Using variable frequency motor, do not change the voltage, only change the speed, and then change the motor speed, adjust the feed speed. The motor brand is Siemens. The feeder is made of stainless steel

Forced Feeder

This is a feature of cattle feed pellet machine, it is more conducive to granulation of grass-containing feed. It is very necessary for light materials, especially for grass meal and straw meal.

Ring Die Pellet Machine

- We already know that RICHI cattle feed pellet machines are ring die pellet machines.

- The material of RICHI’s cattle feed pellet machine ring die is 4Cr13, which is a stainless steel material with high hardness and high wear resistance. This reduces the frequency of replacement of wearing parts and does not corrode feed pellets.

- Large output can meet production needs and long-term supply of enterprises. The capacity of flat mold pellet machine is 100-1000kg/h, but the capacity of cattle feed pellet machine can reach 1-40t/h.

- Ring die compression ratio. The adjustable range of the ring die compression ratio of pellet machine is larger than that of the flat die pellet machine, and the finish of the feed pellet produced is better than that of the flat die pellet machine. The compression ratio is the ratio of the effective thickness of the ring die hole to the minimum diameter of the ring die hole, which is an index reflecting the extrusion strength of pellet feed. The larger the compression ratio, the stronger the extruded pellet feed. The compression ratio of cattle feed pellets is usually 1:8-1:12. The size of cattle feed pellets generally is 5-8mm.

- Our ring die is easy to disassemble. The ring mold can be replaced to produce feed pellets of different sizes. In addition, the ring die is also a loss part. After the production time is long, the aperture of the ring die will be larger and larger, the powder produced will be more and more, and the feed pellet compactness is not enough. At this point, the ring mold needs to be replaced. Our international customers replace ring molds about once a year.

RICHI Machinery’s Requirements for Cattle Feed Pellet Production

- Qualified cattle pellet feed. Pellet appearance is smooth, no cracks, uniform length. After storage and handling, the above requirements can still be maintained when feeding animals.

- To produce the most qualified pellet feed with the least energy and the lowest cost.

How to Improve Cattle Feed Pellet Quality and Reduce Powder?

- Enhancement conditioning;

- Improving the fineness of the powder;

- Reducing capacity of cattle feed pellet;

- Sharpening the cutter and adjusting the cutter position;

- Adding binder;

- Formula adjustment;

- Increase the length-diameter ratio of the cattle feed pellet machine die.

If the compression ratio, quality and appearance requirements of pellet products are high, and the output is large, please choose RICHI ring mold pellet machine—cattle feed pellet machine. Of course, we have more models of animal feed pellet machine for you.

Contact us to customize for you

SERVICES WE PROVIDE

About RICHI Machinery

RICHI Machinery has a first-class team, intact for customers to carry out pre-sale, sales and after-sales service. And, after the completion of the project, we will always track the customer’s production situation and solve the problems in production in time.

First of all, the business personnel have a very deep understanding of animal feed pellet machines, the feed pelletizing industry is also very good at. Be able to answer many doubts of customers and solve problems for customers.

Secondly, we have professional engineers and workers to strictly control the quality and output of feed pellet production. After layers of testing and screening, to provide customers with the better solution.

Thirdly, we will have professional personnel who have only followed the construction of the entire feed pellet production line to solve the problems in the process until the customer’s project starts and the test is successful.

Successful Cases

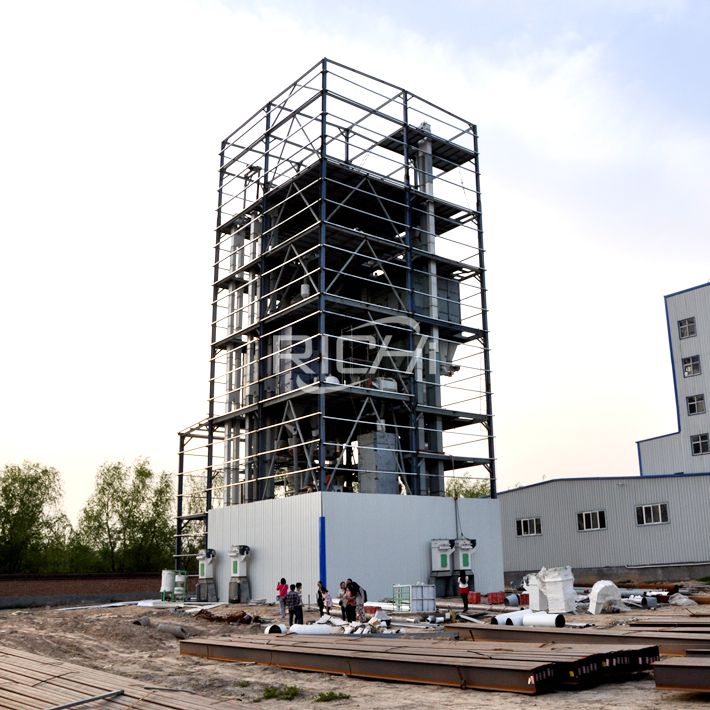

10-12T/H cattle feed pellet plant in US

RICHI Machinery has customized 10-12T/H cattle feed pellet plant for US customer. The cattle feed pellet machine and other equipment used in the production line are all provided by RICHI Machinery.

15-16T Cattle feed pellet plant in Saudi Arabia

RICHI has made such a cattle feed pellet plant for a customer in Saudi Arabia. Customers use the 15-16T/H chicken&cattle feed pellet production line to produce chicken feed pellets, sheep feed pellets and cattle feed pellets.

RICHI Cattle feed pellet machine in India

RICHI Cattle feed pellet machines are also popular in India and around the world. As the manufacturer, it is our responsibility to provide high quality cattle feed pellet machine in India.

cattle feed production plant in Inner Mongolia

In 2015, RICHI Machinery established a cattle feed plant in Inner Mongolia, China. After the project is put into operation, the annual after-tax profit of the pellet plant will be approximately $1.79 million.

There are many more examples to list. Contact us if you want to know more. As China’s leading feed and biomass pellet machinery and equipment manufacturers and exporters, RICHI machinery has been exported to Europe, the United States, the Middle East, Asia, Southeast Asia, Africa and other more than 127 countries and regions.

Cattle feed pellet machine is an important machine for turnkey project of cattle feed pellet plant. The pelletizing production of grass meal in cattle feed is more difficult and complicated than that of grain feed. After years of research, RICHI Machinery has made a major breakthrough in technology and programs. For cattle, sheep, camel ruminant feed manufacturers to provide high quality cattle feed pellet machine. If you are working on a cattle feed, sheep feed or other ruminant feed pellet production project, or want to update a previous feed pellet machine, Please contact us, our sales staff will provide you with feasible solutions and cattle feed pellet machine price.