Cat Litter Production Line

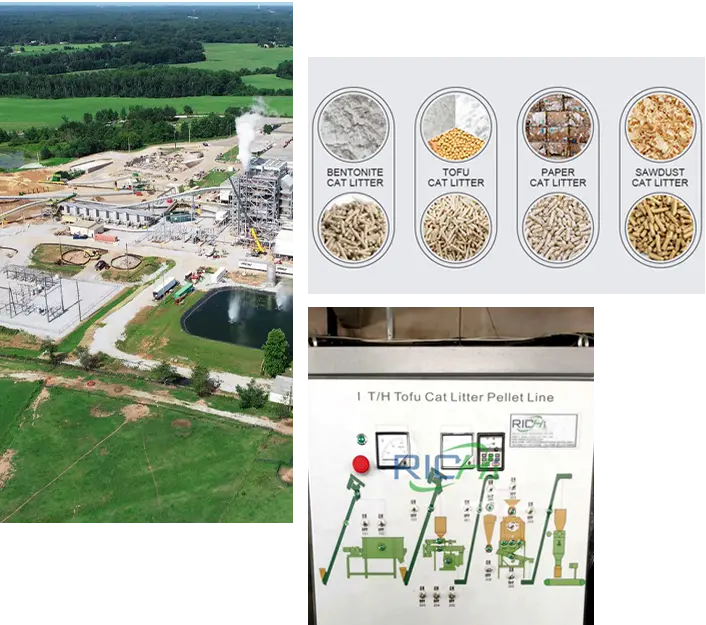

RICHI cat litter production line can produce various types of cat litter pellets, including bentonite cat litter, tofu cat litter, corn tofu cat litter, pine cat litter, wood chip cat litter, sawdust cat litter, waste paper cat litter, etc. Because RICHI’s equipment has excellent performance and high production capacity, RICHI can provide advanced production processes and high-quality complete sets of equipment for commercial cat litter manufacturers and industrial cat litter factories. If you would like to learn about the production process of cat litter pellets or purchase cat litter equipment, you can contact us.

Introduction of RICHI cat litter production line

0.3-60T/H cat litter pellet production lines for sale

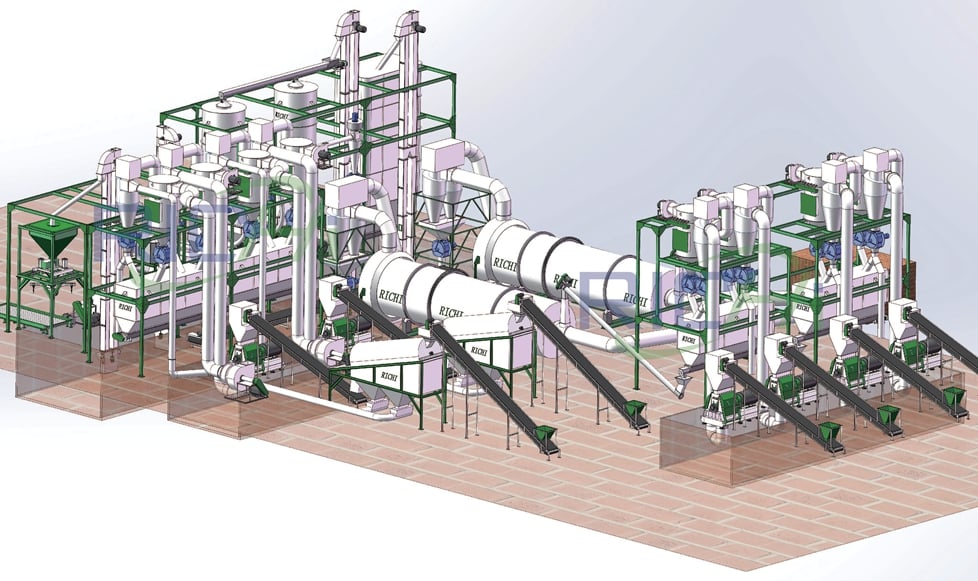

RICHI Machinery can not only provide customers with standardized cat litter pellet production lines with the capacity of 0.3-60T/H, but also customize cat litter pellet production solutions according to customers’ raw materials, plant size, and final size and quality of cat litter pellets.

- RICHI cat litter pellet production line capacity: 0.3-60T/H

- Processed raw materials: bentonite, montmorillonite, pine, wood chips, pulp, soybean pulp, soybean fiber, corn starch, paper scraps, waste paper and other raw materials that can be processed into cat litter pellets.

- Cat litter pellet diameter: 1.5-8mm

- Main equipment: cat litter pellet machine with ring die, raw material crusher, mixer, cat litter pellet dryer, pellet cooler, packing machine, conveying equipment and so on.

- Customizable solutions: Each section and production equipment of the RICHI cat litter production line can be customized. The purpose of customized design is to meet the production needs of customers, rationally use the budget and project footprint, and maximize the return on investment.

Types of RICHI cat litter production lines

The production lines are divided into 4 types according to the common types of cat litter, please contact us for more types of granulation.

Bentonite cat litter Production Line

- Main raw material: bentonite, montmorillonite, clay

- Capacity: 0.5T/H-60T/H

- Cat pellet diameter: 1.5-8mm

- Features: By grinding, mixing, granulating, drying, cooling and other processes, bentonite and other materials are processed into cat litter pellets.

Corn Tofu cat litter Pellet Line

- Main raw materials: Tofu residue, corn starch,

- Capacity: 1T/H-45T/H

- Cat pellet diameter: 1.5-8mm

- Features: Efficient production of high-quality tofu cat litter pellets. Don’t worry about your cat accidentally eating the tofu cat litter.

cat litter paper pellet making machine

- Main raw materials: waste paper, pulp

- Capacity: 0.7T/ H-40T/H

- Cat pellet diameter: 1.5-8mm

- Features: With waste newspaper, waste book, waste paper, pulp as the main raw materials, suitable for small, medium and large-sized waste paper cat litter factory.

Pine cat litter Pellet Production Line

- Main raw materials: pine, wood chips, sawdust

- Capacity: 0.3T/ H-40T/H

- Cat pellet diameter: 1.5-8mm

- Features: Pine cat litter pellets come from wood. Natural and harmless, and environmentally friendly. Strong odor absorption, decomposable.

RICHI cat litter production line solutions

0.3-60T/H cat litter production line solutions for the production of bentonite cat litter pellets, tofu cat litter pellets, wood cat litter pellets, waste paper litter pellets, etc.

- 0.5-1T/H waste paper cat litter pellet production line

- 1-1.5T/H tofu cat litter pellet production line

- 2-3T/H bentonite cat litter pellet production line

- 3-4T/H sawdust cat litter pellet manufacturing line

- 4-5T/H montmorillonite cat litter pellet line

- 6-8T/H clay cat litter pellet factory

- 8-10T/H pine wood cat litter factory

- 10-20T/H corn tofu cat litter factory

- 20-40T/H bentonite cat litter production line

- 40-50T/H tofu cat litter production line

- 50-60T/H bentonite cat litter factory

If you have the need to order the above cat litter pellet production lines, please contact us.

cat litter manufacturing process and equipment

RICHI cat litter manufacturing process consists of crushing, mixing, granulating, drying, cooling, screening and packing, and the technological process can be adjusted according to specific needs.

Crushing process

The raw materials of cat litter pellets are montmorillonite, blocks of bean curd residue, corn, soybean straw, pine block, waste newspaper, waste paper, etc. These raw materials need to be crushed into powdered raw materials. If the raw materials themselves are powdered, such as montmorillonite, wood chips, corn starch, powdered soybean pulp, paper scraps, etc., the crushing process can be eliminated.

The main equipment of this process is the grinder. RICHI Machinery’s hammer mills have efficient water drop hammer mill, straw grinder, wood chip crushing machine and so on. Customers can choose equipment according to the raw materials.

Mixing process

The mixing process is mainly used to mix powdered materials evenly in order to produce high-quality cat litter pellets. The production of cat litter pellet requires not only one raw material, but a variety of raw materials to be mixed or mixed with additives. For example, tofu cat litter pellets are made from tofu residue, soybean straw powder and corn starch. Therefore, the quality of the mixing process has an impact on the texture uniformity of the cat litter pellets.

The main equipment of this process is the mixer. The single-axis paddle type mixer of RICHI Machinery is suitable for a variety of raw materials, with high mixing efficiency and a high uniformity of 97.7%.

Granulation process

The pelleting process is the core of the cat litter production line, which is used to press the mixed powder material into 1.5-8mm cat litter pellets. The quality of the pelleting process greatly affects the pelleting effect of cat litter pellets, such as pellet firmness, surface smoothness, pellet size and so on.

The main equipment of the pelleting process is the cat litter pellet machine. The production capacity of RICHI Machinery’s ring die cat litter pellet machine ranges from 300LKG/H to 28T/H, depending on the models of the cat litter pellet machine and the raw materials. Small cat litter production line usually choose a cat litter making machine, large production of cat litter factory will choose 2 or more cat litter making machines at the same time for the production of cat litter pellets.

Drying and cooling processes

The high humidity and high temperature of pelletized pellets require timely drying and cooling to facilitate their packaging, storage and transportation. Dried and cooled to room temperature pellets are not easy to break, not easy to deteriorate. In the production line of large quantities of cat litter pellets, natural drying is not practical. For industrial cat litter production lines, drying and cooling processes can improve the production efficiency of cat litter pellets.

The main equipment of the drying process is the cat litter dryer, and the main equipment of the cooling process is the pellet cooler. RICHI Machinery provides advanced drying and cooling equipment so that cat litter pellets do not crack during drying and cooling.

Screening process

The screening process carries out the final screening of the formed cat litter pellets, the qualified cat litter pellets are screened out, and the larger and smaller pellets or the pulverized pellets are returned to the previous crushing, mixing or pelleting process. This can further improve the size uniformity and quality of the cat litter pellets, and the unqualified pellets will be reused.

The main equipment of screening process is screening machine, RICHI Machinery has SFJZ series vibration grading screener and SFJH series rotary vibration grading screener. Rotary vibration grading screener can be customized according to the need for two or three layers of screen. Customers can choose according to their own needs.

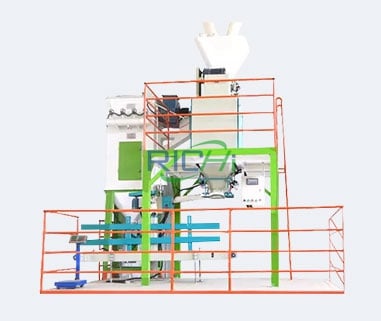

Packing process

The packing process involves weighing and packaging the final, finished cat litter pellets for storage, transport and sale. Small production lines of cat litter pellets can be manually weighed and packaged, which can save equipment costs in the packaging system. However, large cat litter production lines often adopt automated packaging systems.

RICHI automatic packing system includes packing machine, automatic weighing and sewing machine. Its advantages are high weighing accuracy, labor saving, suitable for medium and large cat litter factory, large output cat litter pellet production line.

How to choose the right cat litter productioin line?

Choosing your own cat litter pellet production line needs to be based on your own raw materials, budget, plant size, cat litter pellet capacity and size.

Choose a reliable supplier

Cat litter pellet production equipment belongs to medium and large mechanical equipment, and a complete cat litter pellet production line needs a complete set of cat litter pellet manufacturing equipment. Besides, you may also need to have installation and after-sales service. Therefore, it is very necessary to choose a reliable cat litter equipment supplier, especially for cross-border trade. It is best to choose a supplier with its own factory, which can guarantee the quality and delivery time of the equipment, and can buy the equipment at the factory price. You can view a company’s qualifications and experience through the official website, and you can also visit the factory site.

Identify cat litter production solutions

There are a variety of solutions for the cat litter production line, which vary according to the needs of the customer. Tell us your raw materials, budget, plant size, and the quantity and size of cat litter pellets you want to produce, and we will customize your own cat litter pellet production solution for you. For example, the needs of the sections, the design of the process, the selection of the conveying equipment, the height of the equipment, etc. We can design and modify the solution for the customer until the customer is satisfied.

Choose the right equipment for you

Based on the litter pellet production solution, choose the right type of equipment for you. The choice of equipment should pay attention to quality, operation stability, service life, maintenance frequency and cost. Each device has specific parameters and corresponding output, and it is necessary to carefully check before buying the machine, so as not to buy the unsuitable machine and cause losses. If you choose RICHI Machinery, we have taken into account the equipment and price of the equipment for customers in the solution design, customers can buy without worry.

Why choose RICHI Machinery?

Let’s take a look at the advantages of RICHI Machinery and RICHI cat litter production lines.

Advantages of RICHI Machinery

RICHI Machinery has its own pellet equipment manufacturing factory, you can visit the factory at any time to understand the production process of cat litter pellet production equipment. We will have dedicated staff to meet you. RICHI provides customers with one-stop service, from consulting, design, equipment manufacturing, to delivery, installation, commissioning, training and after-sales, so that customers of the construction of cat litter production line is worry-free.

Advantages of RICHI cat litter production line

Section modular, flexible collocation, personalized customization. Each section of the production line can be combined by itself, not the entire line must be purchased, so that customers can choose sections according to their own needs. Save customers’ investment and maximize productivity. RICHI designs personalized solution for customers, will not let customers waste every penny spent. Customers in the project in making money is our goal.

Global cases of RICHI cat litter production line

We have built cat litter pellet production lines for customers in many countries around the world, and won the recognition of customers.

5-6T/H cat litter production line in UK

2T/H tofu cat litter pellet line in Malaysia

1T/H tofu cat litter making machine in Thailand

8T/H sawdust cat litter factory in Australia

2T/H Bentonite cat litter pellet line in Indonesia

4T/H Bentonite cat litter production line in USA

10T/H cat litter production line in China

2T/H corn tofu cat litter production line in Romania

You may need

RICHI provides high quality and efficient production equipment for cat litter production line.

Cat litter hammer mill

Price: $5,000-$35,000

wood sawdust grinder

Price: $5,000-$20,000

cat litter mixer

Price: $2,500-$40,000

Cat litter pellet dryer

Price: $100,000-$220,000

Cat litter pellet cooler

Price: $4,000-$20,000

Cat litter Pellet screener

Price: $2,000-$10,000

Pellet packing system

Price: $5,000-$20,000

…

4R SERVICE

Worry-Free All the Way

Reliability

We are committed to providing reliable equipment and services. You can fully rely on RICHI Machinery to ensure the stability and efficiency of your production process.

Responsivene

We promise to maintain a rigorous attitude throughout our entire business. Strive for excellence and meticulousness are the most basic concepts we follow.

Rigorousness

We promise to respond quickly when you need us. No matter what challenge or need you face, our team will provide you with a solution at an efficient pace to ensure your business always runs smoothly.

Reassurance

We promise to provide one-stop service so that you have no worries throughout the process. RICHI Machinery will provide you with full reassurance.