Cat Litter Pellet Machine

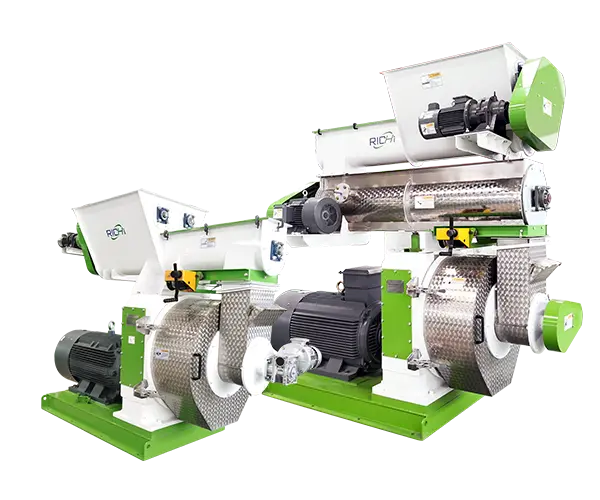

Cat litter pellet machine is an equipment that mechanically presses powdered raw materials into cat litter pellets, mainly used in cat litter factory and cat litter production lines. RICHI cat litter pellet machine complies with international standards and has passed ISO and CE certification. High capacity, easy operation, stable running and durable. In order to meet the production needs and obtain commercial profits, many cat litter pellet manufacturers around the world are choosing RICHI cat litter pelleting machine.

Introduction of RICHI Cat Little Pellet Machine

RICHI cat litter pellet machine has wide applications and can process many different types of raw materials, including pine, wood chips, sawdust, bentonite, Tofu residue, soybean fiber, corn starch, waste paper, pulp and so on.

- Type: Ring die granulator

Our cat litter pellet making machine is a ring die granulator, which is similar in structure and working principle to the RICHI wood pellet machine and feed pellet press. Ring die granulator is not only high yield, the production of cat litter pellets is also uniform in size, high molding rate, moderate hardness, not easy to break, and more friendly to cats.

- Price range: 7,000-100,000 US Dollars

In the same type and quality of products, RICHI’s cat litter pellet making machine price is lower. Because we have our own technology and factory, we can directly provide factory price to customers. In addition, we continue to optimize the process and scale of equipment production, reduce product costs, while ensuring quality.

- Pellet diameter: 1.5-12mm

The cat litter pellet diameter is determined by the inner diameter of the ring die hole. The opening diameter of the die hole of RICHI Machinery is generally 1.5-12mm. If you want a smaller diameter of 0.5-1.5mm litter pellets, you can contact us for details.

Classification of RICHI cat litter pellet machine

The common types of cat litter on the market are bentonite cat litter, tofu cat litter, sawdust cat litter, waste paper litter and so on. RICHI Machinery’s cat litter pellet making machines can produce different types of cat litter pellets from different raw materials.

Bentonite cat litter pellet machine

- Main raw material: bentonite

- Capacity: 3T/H-28T/H

- Final pellet size: 1.5-12mm

- Advantages of bentonite cat litter: high yield, strong water absorption, good touch, dust-free and tasteless.

Tofu cat litter maker

- Main raw materials: Tofu residue, corn starch

- Capacity: 1.5T/H-14T/H

- Final pellet size: 1.5-12mm

- Advantages of tofu cat litter: natural, good unity, good deodorization. Not afraid of cats eating, good safety.

Waste paper cat litter making machine

- Main raw materials: waste paper, pulp

- Capacity: 0.7T/ H-5t /H

- Final pellet size: 1.5-12mm

- Advantages of waste paper cat litter: environmentally friendly and degradable. After your cat urinates, the litter turns gray and is easily recognizable.

Sawdust cat litter granulator

- Main raw materials: pine, sawdust

- Capacity: 0.3T/ H-4.5t /H

- Final pellet size: 1.5-12mm

- The advantages of sawdust cat litter: large pellets, not easy to take out, not easy to roll, good stability.

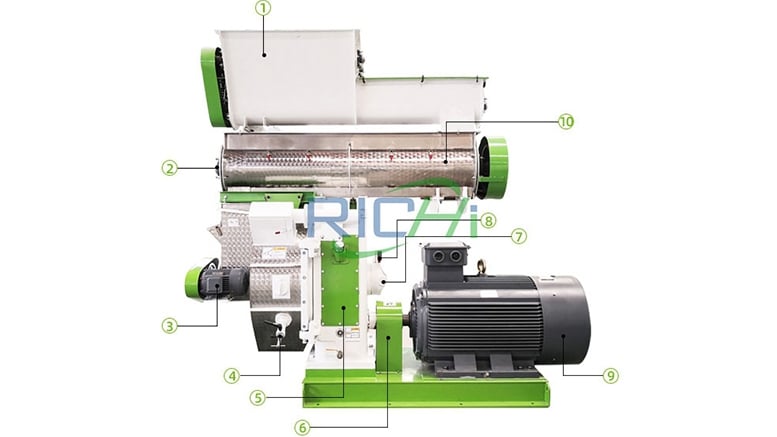

Details of RICHI cat litter pellet machine

Through the structure and working principle, more in-depth understanding of how does the RICHI cat Litter pellet machine work?

Components of RICHI cat litter pellet machine

- Anti-cake device for frequency feeder: the device can prevent the material from arching and help the feeder feed the material evenly.

- SKF bearing

- Forced feeder motor: help materials that do not flow easily, such as wood chips, to enter the pelletizing chamber smoothly.

- Cutter assembly: control the length of cat litter pellets.

- Gear box

- Shaft coupling: adopt the international advanced level of compensation type snake spring coupling.

- Safety assembly: protect the machine.

- Limit switch

- Siemens motor

- Stainless steel conditioner: Selected according to whether the raw material requires steam modulation.

Working principle of cat litter pellet making machine

The prepared granulated material is sent to the feeder, which then sends the material evenly to the chute. The material is fed into the pelleting chamber under the combined action of gravity, a forced-feeder and a switch-plate. The material is then extruded by the rotating press roller and the ring die and discharged through the ring die holes. The final cutter cuts the discharged material into granular cat litter.

The process is mechanical extrusion, which simply turns loose materials into compact pellets. Therefore, the cat litter pellets produced by our cat litter pellet maker are safe and harmless, and there is no chemical pollution to cats and people.

Besides, customers can equip the pellet machine with a conditioner according to their own materials and pelletizing needs. In the pelletizing process of cat litter, the role of the conditioner is to mix the steam with the material, improve the viscosity and plasticity of the cat litter raw materials, and improve the pelletizing effect and yield of the cat litter.

What are the advantages of RICHI cat litter making machine?

If you are considering buying a cat litter making machine, be sure to look at the advantages of the RICHI cat litter making machine before making a decision.

High quality and durable

The material of RICHI cat litter making machine is carefully selected according to the production characteristics of cat litter pellet. For example, the parts in contact with the material are made of stainless steel, which has the advantages of corrosion resistance, easy cleaning and long service life. The ring die uses 42CrMo, compared with carbon steel, RIHCI’s ring die is more wear-resistant, with high surface hardness and long service life. The cat litter pellets are more smooth and shiny. The main accessories are selected from international first-class brands, such as Siemens motors and SKF bearings, to ensure the operation of the machine.

Stable operation and high safety

Cat litter production lines are generally built on steel frames, and the stable operation of the machine on the steel frames is very important. Siemens motors, SKF bearings and serpentine spring coupling used in the cat litter making machine are all world-class. These accessories can make the machine run more stable. Reduce noise and machine damage. RICHI’s ring die pellet machines are also equipped with safety pins. When the machine is overloaded, there is a limit switch to shut down the machine, thus protecting the machine and the motor.

Complete models and can be customized

Our factory specializes in the production of granulation equipment, each machine and its accessories models are very complete, can meet the various production needs of different customers. In addition, the raw materials for pellet production are diverse, and customized equipment is often needed by customers. The ring die, conditioner, feeder, motor and other accessories of RICHI cat litter making machine can be customized according to the specific situation of customers. The advantage of customization is that it is more reasonable, does not waste power, and can meet the production of various types of particles.

Specific models and parameters of RICHI cat litter pellet machines

The following table shows some common models and parameters of RICHI cat litter pellet machine, as well as the capacity when making bentonite cat litter, tofu cat litter, waste paper cat litter, wood litter.

| Model | MZLH320 | MZLH350 | MZLH420 | MZLH520 | MZLH768 | MZLH858 |

| Main Motor Power(kw) | 22KW 8P | 37KW 8P | 90KW 8P | 132KW 8P | 250KW 8P | 280KW 8P |

| Anti-caking Feeder Power | 1.5KW | 1.5KW | 1.5KW | 2.2KW | 3KW | 3KW |

| Forced Feeder Power | 0.55KW | 0.55KW | 0.55KW | 0.75KW | 1KW | 1KW |

| Capacity(Raw materials: Bentonite) | 3 T/H | 5 T/H | 8 T/H | 10 T/H | 25 T/H | 28 T/H |

| Capacity(Raw materials: Tofu cat litter) | 1.5 T/H | 2.5 T/H | 4 T/H | 5 T/H | 12.5 T/H | 14 T/H |

| Capacity(Raw materials: Waste paper) | 0.7 T/H | 1 T/H | 2 T/H | 3 T/H | 4 T/H | 5 T/H |

| Capacity(Raw materials: Sawdust) | 300-400 KG/H | 500-700 KG/H | 1-1.2 T/H | 2-2.5 T/H | 2.5-4 T/H | 3-4.5 T/H |

| Final Pellet Diameter | 1.5-12mm | 1.5-12mm | 1.5-12mm | 1.5-12mm | 1.5-12mm | 1.5-12mm |

| Weight | 2500KG | 3500KG | 4000KG | 4500KG | 5000KG | 5500KG |

| Dimension(mm) | 2200*900*1300 | 2500*1100*1600 | 2800*1150*1730 | 3000*1260*1860 | 3300*1500*2000 | 3500*1600*2180 |

| Ring Die Diameter | 320mm | 350mm | 420mm | 520mm | 762mm | 858mm |

For your own cat litter pellet making machine

CE ISO Cat Litter Pellet Machine with 0.3-28T/H Capacity

RICHI cat pellet machine can process pine, sawdust, bentonite, waste paper, and Tofu cat litter, etc. High output, moderate price, suitable for cat litter factory and cat litter production lines.

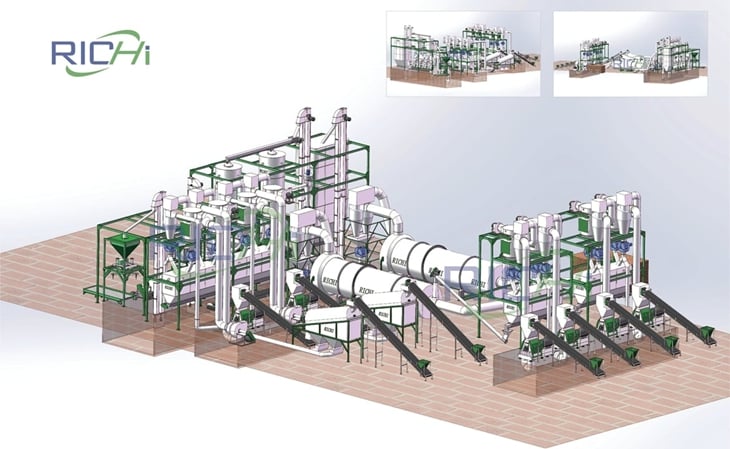

Cat litter production line

Common cat litter manufacturing process:

Crushing – Mixing – Pelletizing – Drying – Cooling – Screening – Packing. RICHI Machinery’s cat litter pellet production process is modular, allowing customers to choose according to their raw materials and their production needs.

Auxiliary equipment

In addition to the cat litter pelleting machines, what other auxiliary equipment does RICHI have?

Cat litter material hammer mill

Raw material mixer

Cat litter dryer

Cat litter cooler

Pellet screener

Automatic packaging machine

Global Projects of Cat litter pellet machine

The capacity of RICHI cat litter pellet machine ranges from 0.3T/H to 28T/H, and the cat litter pellet production line projects that RICHI Machinery can undertake range from 0.3T/H to 60T/H.

500kg/h cat litter production line

- Country: Indonesia

- Time: June 6, 2022

- Cost: 30,000 – 40,000 US Dollars

- Capacity: 500kg/h

- Cat litter pellet diameter: 2mm

- Cat litter production process: crushing – mixing – pelletizing – cooling – screening – packing

- Main equipment: hammer mill, mixer, cat litter pellet maker with conditioner, cat litter pellet cooler, conveyor

- Features: The production line is a simple production line with low cost and small footprint. Because the output is not high, the packaging section adopts manual packaging.

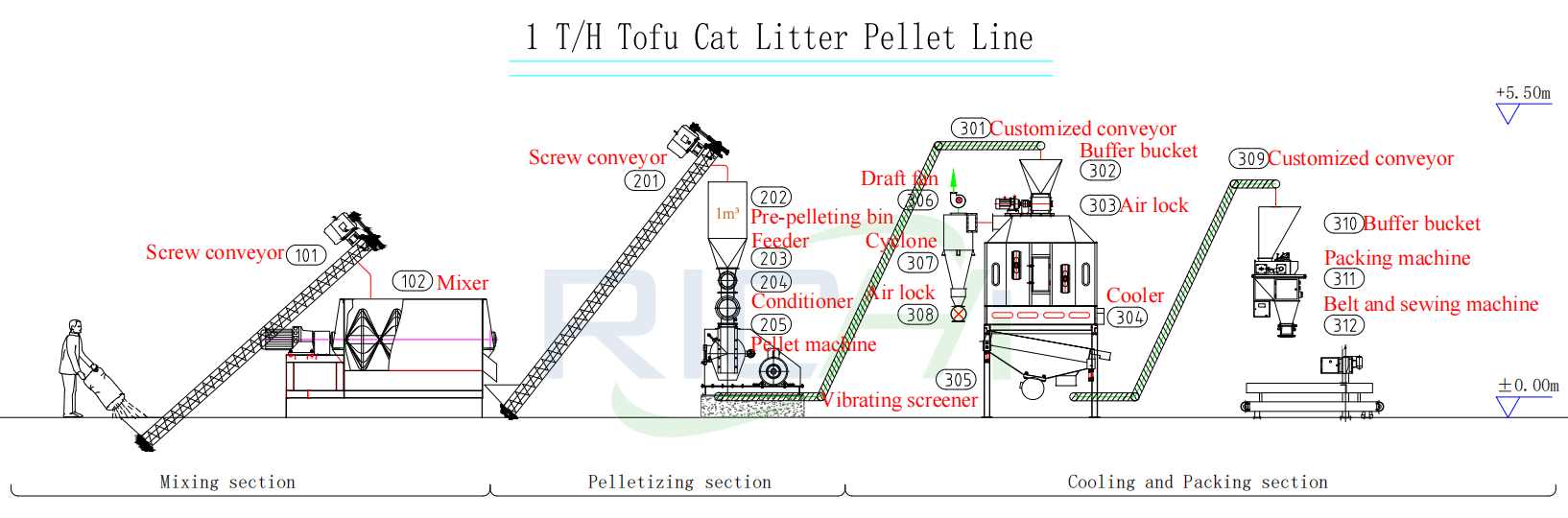

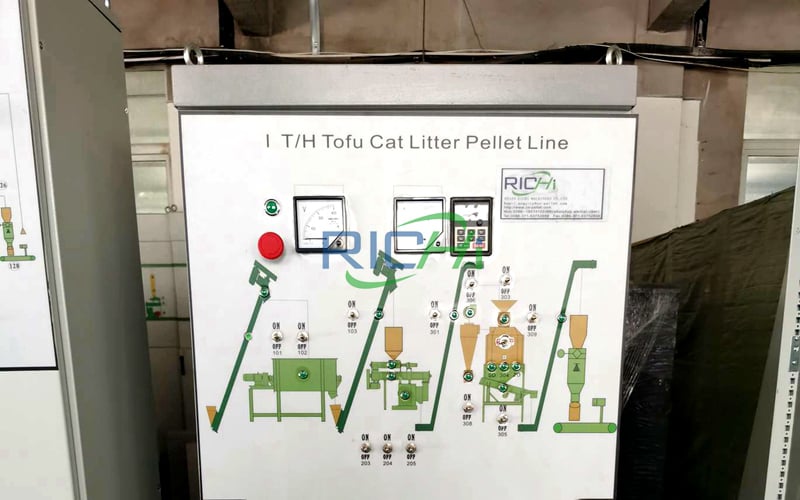

1T/H Tofu cat litter production line

- Country: Thailand

- Guide price: 40,000-50,000 US Dollars

- Capacity: 1T/H

- Equipment height: 5.5m

- Cat litter production process: mixing – pelletizing – cooling – screening – automatic packing

- Main equipment: mixer, cat litter pellet making machine with conditioner, cat litter pellet cooler, packing system, conveyor

- Features: The customer’s raw materials do not need to be crushed, eliminating the crushing section. Packing section adopts packing machine and belt and sewing machine, high precision and saving manpower.

Tofu cat litter Pellet production line

- Country: Malaysia

- Main Raw material: Tofu residue, corn starch

- Cat litter production process: mixing – pelletizing – dring – cooling – screening – automatic packing

- Main equipment: mixer, Tofu cat litter pellet machine, cat litter pellet dryer, cat litter pellet cooler, packing system, conveyor

- Features: The raw materials do not need to be crushed, and the drying section is added in the middle of the granulation and cooling sections, and the cat litter with high humidity is dried with the cat litter pellet dryer.

2T/H cat litter pellet line

- Country: Russia

- Time: July 25, 2024

- Cost: 40,000-50,000 US Dollars

- Raw materials: clumping filler based on vegetable raw materials – soy, starch, corn.

5-6T/H cat litter factory

- Country: England

- Time: Oct 13, 2023

- Guide price: 100,000-200,000 US Dollars

- Features: Customized

2-2.5T/H cat litter pellet line

- Country: Italy

- Time: July 22, 2023

- Guide price: 100,000-150,000 US Dollars

- Features: Customized

You may also like

Why buy a cat litter making machine?

Modern people are increasingly interested in cat ownership, and most people keep cats indoors. In order to easily and hygienically dispose urine and feces of their cats, almost every cat owner buys litter for their cats. High quality cat litter has strong water absorption capacity, inhibits bacteria, deodorizes, is environmentally friendly and easy to clean. As a necessity for cat ownership, the purchase of cat litter is also increasing year by year.

As can be seen from the chart on the right, the global cat litter market will reach USD 5.37 Billion by 2027. Therefore, the cat litter factory market also has huge potential. As people’s demand and quality requirements for cat litter become higher, cat litter factory also need to introduce new cat litter pellet machines to cope with market changes. At the same time, the raw material price of cat litter is relatively low, so the cat litter pellet making machine is also a good investment and entrepreneurship project, which can bring continuous benefits to buyers.

If you want to produce cat litter that meets the needs of the market, come and buy RICHI cat litter making machine.

About RICHI Machinery

Henan RICHI Machinery Co., Ltd. was founded in 1995, is the leader of China’s pellet machinery industry, master the core technology of pellet machinery equipment manufacturing. RICHI cat litter pelleting machine is already recognized by cat litter pellet factory, and has been sold to many countries around the world.

Quality certification

RICHI Machinery has been focusing on pellet machinery equipment for 30 years. Not only RICHI factory has passed the BV certification, but all the equipment and accessories produced are in line with international standards. All products have passed CE, ISO and other international certifications. There are also multiple breakthroughs and utility model patent certificates in the design of pellet machines and ring dies.

Global case

Our products have been exported to Canada, Germany, the United States, Kazakhstan, Russia, Malaysia, Australia, South Korea, Uzbekistan, Singapore, Egypt, Palestine, Sudan, New Zealand and other 128 countries and regions. More importantly, we have won unanimous praise from customers and reached second co-operation with many customers.

Turnkey service

We provide turnkey service to our customers, including consultation, design, manufacture, testing, delivery, installation, training and after-sales services. The turnkey service allows customers to purchase a cat litter pellet machine or customize a cat litter production line without worry. If you are looking for a reliable cat litter pellet machine supplier, RICHI Machinery is a good choice.

4R SERVICE

Worry-Free All the Way

Reliability

We are committed to providing reliable equipment and services. You can fully rely on RICHI Machinery to ensure the stability and efficiency of your production process.

Responsivene

We promise to maintain a rigorous attitude throughout our entire business. Strive for excellence and meticulousness are the most basic concepts we follow.

Rigorousness

We promise to respond quickly when you need us. No matter what challenge or need you face, our team will provide you with a solution at an efficient pace to ensure your business always runs smoothly.

Reassurance

We promise to provide one-stop service so that you have no worries throughout the process. RICHI Machinery will provide you with full reassurance.