Biomass Pellet Production Line

Biomass pellet production line has a variety of solutions and can also be customized according to your own needs. If you are looking for a quality biomass pellet production line supplier or manufacturer, you can contact us.

RICHI MACHINERY

0.5-45T/H Biomass Pellet Production Line Details

Biomass pellet production line makes agricultural and forestry waste, urban organic waste, etc., into biomass pellet fuel.

Biomass pellet production line includes the main processes of pretreatment, crushing, drying, mixing, pelletizing, cooling, packaging.

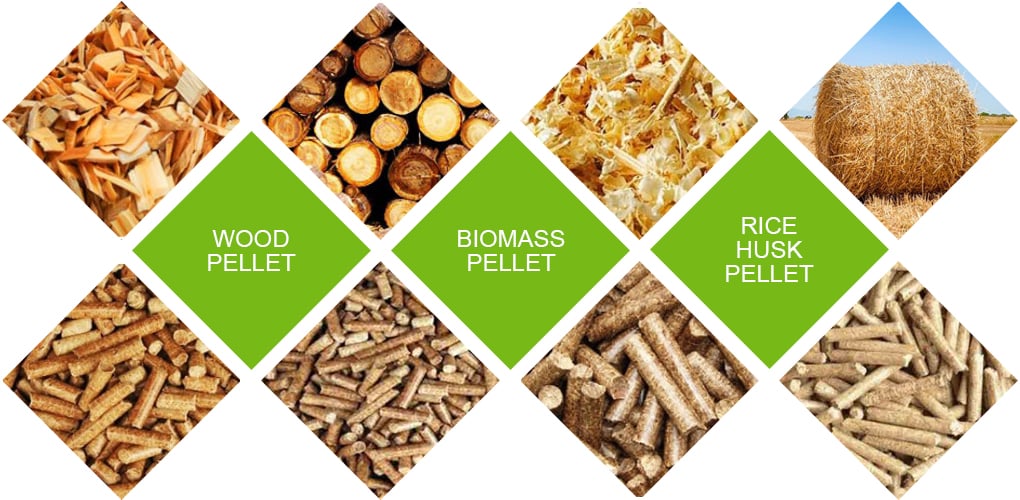

- Common biomass raw materials: wood chips including forestry waste, wood blocks and shavings from wood processing, waste furniture, etc. Straw includes corn straw, wheat straw, sorghum straw, etc. Crop shells include peanut shell, rice shell, cottonseed shell, oil tea shell, etc. Grasses include alfalfa; Organic fertilizer, etc.

- Uses of biomass pellets: biomass pellets are mainly suitable for combustion; 100% grass pellets can be used as feedstock formula for ruminant feed to form complete feed pellets; Organic fertilizer pellets can be used to fertilize plants.

- Size of biomass pellet: 6-12 mm

- Capacity of biomass pellet: 0.5-45 t/h

What are the types of biomass pellet production lines?

Biomass raw materials come from a wide range of sources. Due to the difference in the type, size, hardness, moisture content and initial form of biomass raw materials, the process and equipment of biomass pellet production line are also different. There are many biomass pellet production lines, and RICHI will plan each production line in combination with raw materials, customers’ capacity needs, investment budgets, etc. According to the classification of biomass raw materials, biomass pellet production lines include:

- Wood pellet production line

- Peanut shell pellet plant

- Sawdust pellet mill

- Straw pellet production line

- Grass pellet production line

- Alfalfa pellet production line

- Organic fertilizer pellet mill

- …

Common biomass pellet production lines

There are two main types of common biomass pellet production lines: wood pellet production line and straw pellet production line.

wood pellet production line

Log treatment – chipping – crushing – drying – homogenizing – pelleting – cooling – packaging

If the raw material is wood sawdust, the crushing process is not necessary. Because the sawdust can directly enter into the drum dryer. If the raw material is dry wood sawdust, grinding and drying are not necessary.

The equipment used in the wood pellet production line is drum wood chipper, template crusher, wood hammer mill, rotary drum drying machine, biomass pellet making machine, counterflow cooling machine, vibration screen, finished packaging scale, thermoplastic sealing machine, conveying equipment, buffer bin, negative pressure ventilation system, dust removal system and so on.

straw pellet production line

Breaking bales – crushing – drying – homogenizing – pelleting – cooling – packaging

All kinds of grasses, hay bales, all kinds of agricultural leftovers including straw, rice husks, etc. are suitable for this straw pellet production line, and their pellet yields are also roughly the same.

The equipment used in the straw pellet production line are hay cutter, straw bale breaker, hanging iron remover, grass special crusher, rotary drum drying machine, air cannon, biomass pellet making machine, counterflow cooling machine, rotary grading screen, finished goods bin, tonnage bag scale and so on.

The hay cutter breaks excessively long materials, such as corn stalks, directly into 3-5 cm. Bale crusher is a bale breaker used to break baled grass or straw. Bale breaker dust is large when used, it is recommended to work outdoors. The front end of the grass crusher is usually equipped with a belt conveyor for feeding, and the feed port has a lifting plate to force feeding to improve the yield of the grass crusher.

Differences of wood and straw pellet production lines

Different raw materials, production sections and equipment will be different.

Pretreatment section, processing of biomass raw materials in their initial form. The wood is hard, and some tree trunks need to be split first with a cleaver and then the bark is removed with a peeling machine. Then enter the wood chipper for chipping processing. Too long straw needs a hay cutter, and straw bales need a bale breaker.

Crushing section. Wood chips crushed into sawdust commonly used water drop type hammer mill. Because the grass and straw are lighter, a grass crusher is usually used.

The bulk weight is different, sawdust is 400 kg/m3, grass powder and straw powder is 120-150 kg/m3.

The production capacity of the biomass pellet making machine is different, which will be introduced next.

biomass pellet machine

Biomass pellet making machine is the core equipment of biomass pellet production line, and it is also an essential equipment. RICHI Machinery’s MZLH series biomass pellet making machine, due to different raw materials, the capacity of each model of biomass pellet making machine is not the same. In the case of the same model of pellet machine, the wood pellet capacity is the least, the capacity of grass pellet and straw pellet is in the middle position, and the capacity of organic fertilizer pellet is the highest.

Parameter list of MZLH series biomass pellet making machine

| Model | MZLH320 | MZLH350 | MZLH420 | MZLH520 | MZLH768 | MZLH858 |

| Anti-caking Feeder Power | 1.5KW | 1.5KW | 1.5KW | 2.2KW | 3KW | 3KW |

| Forced Feeder Power | 0.55KW | 0.55KW | 0.55KW | 0.75KW | 1KW | 1KW |

| Pellet Machine Power | 37KW | 55KW | 110KW | 160KW | 250KW | 280KW |

| Capacity(wood sawdust,biomass) | 300-400KG/H | 500-700KG/H | 1.0-1.2 T/H | 2.0-2.5 T/H | 2.5-4T/H | 3-4.5T/H |

| Capacity(grass,straw) | 600-800KG/H | 800-1000KG/H | 1.5-2T/H | 3-4T/H | 5-7 T/H | 8-10 T/H |

| Capacity(organic fertilizer) | 1-2 T/H | 3-4 T/H | 5-6 T/H | 7-8 T/H | 9-10 T/H | 10-12 T/H |

| Final Pellet | 6-12mm | 6-12mm | 6-12mm | 6-12mm | 6-12mm | 6-12mm |

| Weight(KG) | 2500 | 3500 | 4000 | 4500 | 5000 | 5500 |

| Dimension(mm) | 2200*900*1300 | 2500*1100*1600 | 2800*1150*1730 | 3000*1260*1860 | 3300*1500*2000 | 3500*1600*2180 |

RICHI MACHINERY

FAQs of biomass pellet production line

01

What are the advantages of biomass pellets?

Biomass pellets can be used as fuels, and the raw materials are derived from renewable agricultural and forestry plants, and are all waste or scraps. Compared with fossil fuels, biomass pellet fuels are more environmentally friendly. Biomass pellet fuels are more efficient than burning wood directly.

Biomass pellets can be used as feed for ruminants, such as cattle, sheep, horses, camels. The advantage of pellet feed is that it is easy to transport and store. The mixed feed of forage and grain can be used as complete pellet feed for ruminants, which is conducive to the absorption and growth of ruminants.

Biomass pellets can be used as fertilizer and added to the soil to allow plants to obtain nutrients. Compared to the original form of organic fertilizer, biomass pellets are more convenient and more friendly to the fertilizer worker.

02

Wood pellet production line? Or straw pellet production line?

Wood and straw are both biomass raw materials, but their pellet production lines are not exactly the same. Logs, branches, wood chips, shavings need drum wood chipper or wood chip crushing equipment, choose wood pellet production line. Wheat straw, corn straw, grass, and fruit husks need a grass crusher, choose straw pellet production line.

Production sites and prices also affect the configuration of production lines. In the choice of biomass pellet production line, you can send an inquiry, provide your raw materials, site, capacity requirements and pellet usage, we will provide you with a suitable biomass pellet production line.

03

How to choose the equipment on the biomass pellet production line?

The model of the equipment is selected according to the output, raw materials and actual conditions.

The volume of the mixer should be calculated according to the capacity and the density of the material, and the most appropriate size should be selected to achieve the highest cost performance. Mixer with bottom door opening is 10 P/H, wood sawdust in accordance with 400kg/m3, 1m3 mixer capacity can reach 4T/H. And then straw and grass according to 120 -150kg/m3, the capacity of 1m3 mixer is 1.2-1.5T/H.

Calculating the output of the rotary drum drying machine based on 50% moisture dries to 15% moisture.

The capacity of the biomass pellet making machine varies according to the type of raw materials. If there are more than two raw materials, calculating the capacity according to the ratio.

Please contact us for more information about the selection of machine model.

04

Does the biomass pellet making machine need a conditioner? Why do you need an anti-knot arch feed bin and a forced feeder?

Most of the biomass pellet making machines do not need conditioner, because the biomass pellets made are mainly used for combustion or other, and do not need to pass steam for curing. Wood pellet machine, sawdust pellet mill, straw pellet machine, pure grass pellet mill do not need conditioner. If the pellets produced are to be used to feed animals, a mixture of biomass and grain is required. The biomass pellet making machine needs to be configured with a conditioner to meet the needs of ruminants for feed. The higher the proportion of grain in raw materials, the higher the capacity. The specific ratio of ingredients and capacity can contact us for consultation.

05

Can biomass pellet production line process tire fiber?

Of course. We have done tire fiber pellet production line, one of the customers is from Poland, the Polish customer wants to make a 2-3T/H waste tire pellet production line, the raw material is tire cord that does not contain rubber. Tire cord is mainly made of high-strength and high-modulus fiber materials, and most passenger car tires are made of nylon, polyester and so on. The Polish customer wanted to mix tire fiber pellets with concrete and then use them to pave roads to recycle waste. The tire fiber pellet production line we set up for the Polish customer includes MZLH 520 biomass pellet making machine with 132kw main motor power, pulse dust collector, cyclone, draught fan, customized conveyor, SKLN 14*14 counterflow cooler, tonnage bag scale, etc.

The advantages of 2-3t/h tire fibre pellet production line in Poland

- Biomass pellet making machine uauslly has a single layer conditioner, which is conducive to the softening of tire fiber, convenient for forming and pelleting.

- Pulse dust collector has the function of protecting the working environment.

- The customized conveyor replaces the bucket elevator, reducing the height of the plant and eliminating the trouble of digging the pit.

- Tonnage package scale can realize the needs of customers in large quantities of packaging.

06

How much does a biomass pellet production line cost?

The quotation needs to be combined with the price of the selected biomass pellet making machine, the price of other equipment and the number of equipment to calculate. A 2-3 t/h biomass pellet production line costs about $120,000 to $300,000. More different production of biomass pellet production line prices and biomass pellet machine prices, you can send inquiries to consult us.

How to choose a biomass pellet production line manufacturer?

- Examine its technical strength, production capacity and market reputation, and then pay attention to whether the manufacturer has relevant qualification certificates and patented technology.

- Pay attention to the technical characteristics of its biomass pellet production line, raw material adaptability, molding rate, environmental performance and so on. Confirm the service life, maintenance cost, production efficiency, after-sales service, etc.

- Consider the price of equipment, choose the more cost-effective. Choosing a cost-effective manufacturer can reduce investment costs and improve the overall benefit of the project.

Choosing a quality biomass pellet production line manufacturer is critical to ensuring the success of the project. RICHI machinery has the above strength, can provide you with high-quality biomass pellet production line. RICHI machinery also has a lot of practical cases of biomass pellet production line for reference.

1-2t/h sawdust pellet production line in Indonesia, 11-12t/h grazing pellet production line in US, 2.5t/h sawdust pellet production line in Mexico, 2t/h organic fertilizer pellet mill in Mexico, sawdust pellet production line in Iceland, 1-1.2t/h sawdust pellet production line in Congo, 3-5t/h grass pellet production line in Indonesia, 2-3t/h wood pellet machine in Canada, 3-5t/h organic fertilizer pellet machinery in Thailand, 1-1.2t/h wood pellet production line in Taiwan, China, etc. Besides, We have many other cases. RICHI Machinery is a leading enterprise in China’s pellet machinery, including feed pellet machinery and biomass pellet machinery, and it is the trust and praise of customers that have prompted these projects.

29+

Years Experience

1000+

Turnkey Service Projects

127+

Countries and Regions

2000+

Customers