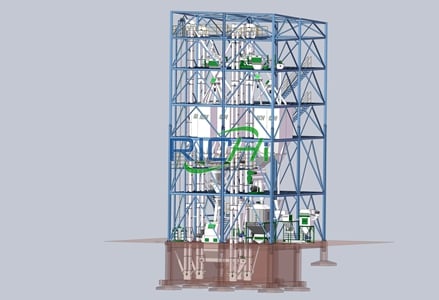

Animal Feed Production Line in Saudi Arabia

RICHI Machinery has built an animal feed production line for a Saudi Arabian customer, the line is used for 5-6T/H cattle feed pellets and 10T/H chicken feed pellets production. The animal feed production plant adopted RICHI SZLH animal feed pelletizer, and the Saudi Arabian customer chose a fully automatic batching system for this animal feed production line.

RICHI MACHINERY

Details of the Saudi Arabian animal feed production line project

Saudi Arabia is leading the feed market in the Middle East. With the increase of animal farming and the improvement of feed standards in the Middle East , the high standard animal feed production business plan has also begun to develop.

- Project name: 5-6T/h cattle feed and 10T/H chicken feed pellets production line in Saudi Arabia

- Project start date: March 30, 2018

- Country: Saudi Arabia

- Customer’s raw materials: corn, soybean meal, alfalfa

- Capacity: 5-6T/h cattle feed, 10T/H chicken feed pellets

- Pellet diameter: 1-12mm

- Main equipment: SZLH animal feed pelletizer with 160kw, feed crusher with 90kw, automatic batching system, feed mixing machine with 3.5T/Batch, feed pellet cooler, pellet crumbler, screen machine, automatic packing system.

- Type of boiler: oil burning boiler

- Project size(Length * width * height): 16m * 8m * 12m

- Project installation: 90 days in total with 4 RICHI’s installation engineers

- Total power of the line: 554kw

- Number of workers required for the production line: 3-4

- Features of the animal feed production line: can produce two types of animal feed pellets, automatic computer batching, customized.

How to set up the 5-6T/h cattle feed and 10T/H chicken feed production line?

The production line is customized by RICHI Machinery, which needs to consider how the mixed raw materials of grass and grain are made into feed pellets.

Determine feed formulation according to animal type

Through different feed formulations, different types and different yields of animal feed pellets are produced. The smaller the proportion of grass in the raw materials, the higher the capacity of the animal feed production line. The Saudi Arabian customer’s cattle feed formula consists of 33% alfalfa, while the chicken feed formula consists of very little grass. Therefore, the capacity of cattle feed pellets with the same SZLH animal feed pelletizer is lower than that of chicken feed pellets.

Find reliable feed equipment supplier

Feed pellet production equipment belongs to medium and large machinery, and the transaction volume of a complete animal feed production plant is also relatively high. Therefore, in cross-border procurement, we need to find a reliable supplier. It is best to have its own pellet equipment manufacturing plant and have rich experience, like RICHI Machinery. In this way, the risk can be minimized or zero in terms of trading, equipment manufacturing, transportation, installation and after-sales.

Design animal feed pelleting process according to raw materials

Different raw materials require different production processes and equipment, such as the crushing of grass and the crushing of grain require different types of hammer mills.

The animal feed pelleting processes includes crushing of alfalfa, drying of alfalfa powder, crushing of corn and soybean meal, automatic batching, powder feed mixing, pelletizing, pellet cooling, pellet crumbling, screening, auto-packing.

Propose solutions according to process flow and plant size

Each processing section has a variety of solutions. For example, the batching system has a PLC batching system independent of the production line and a fully automatic batching system built directly on the steel frame of the production line. They vary in cost and footprint. When we propose animal feed production plant solutions, we combine the customer’s raw materials, production needs, budget and plant size.

Select the equipment according to the production solution

Equipment is the core of the animal feed production line, so we need to choose the most suitable feed pellet production equipment. For the Saudi Arabian project, RICHI selected the right equipment for the customer based on the raw materials, such as SZLH chicken and cattle feed pellet making machine, grass hammer mill, feed crushing machine and so on. Besides, RICHI can customize equipment for customers.

Installation and operation of equipment

After all the above is completed, we wait for the manufacturing and delivery of the equipment, and finally carry out the installation and trial running. It should be noted that for such a large and complex production line, try to find a supplier who can assist in installation and worker training. This can avoid difficulties in the installation process, affecting the progress of the project. It can also avoid operational errors in the animal feed pelleting process that can lead to the shutdown of the animal feed production line. Finally, it will affect the benefit of cattle feed mill.

Advantages of the animal feed production line in Saudi Arabia

Batching and pelletizing are the keys of cattle and chicken feed pellets production, the batching system and SZLH animal feed production machine are also the highlights of the project.

Fully automatic atching system

The calcium content requirement in the feed for chicks and young chickens is 0.9%-1.1%, and during the laying period it should be 3.3%-3.5%. High calcium content in non-egg-producing feeds will cause calcium metabolism disorders, induce urate deposition in the kidneys, and loose stools. Insufficient calcium during the laying period will cause the eggshell become thinner, the egg breakage rate will increase, and induce cartilage disease and egg-laying fatigue syndrome in caged chickens.

Chicken and cattle feed pellet making machine

The calcium content requirement in the feed for chicks and young chickens is 0.9%-1.1%, and during the laying period it should be 3.3%-3.5%. High calcium content in non-egg-producing feeds will cause calcium metabolism disorders, induce urate deposition in the kidneys, and loose stools. Insufficient calcium during the laying period will cause the eggshell become thinner, the egg breakage rate will increase, and induce cartilage disease and egg-laying fatigue syndrome in caged chickens.

Pellet crumbler

pellet crumbler is used in this production line. The smaller the diameter of the ring die hole of the animal feed production machine, the smaller the diameter of the pellets produced, but the capacity will also be reduced. Pellet crumbler can break 3-6mm pellets into 1-2.5mm small size feed pellets, thereby increasing production capacity and reducing energy efficiency of the production line.

The pellet crumbler is installed below the pellet cooling machine, saving on conveying equipment and floor space.

Advantages of chicken and cattle feed pellets

Chicken feed pellets are generally 3-4mm, which has the advantages of rich nutrition, convenient transportation, and not easy to grade. In modern chicken farms, pellet feeds are easier to manage and can accelerate the growth of chickens.

Cattle feed pellets can generally be 6-8mm, the production line of cattle feed pellets are complete cattle feed pellets, containing fiber, energy, protein and various trace elements, can meet the taste and nutritional needs of cattle at the same time.

Can process a variety of raw materials

The production line can process a wide range of raw materials, such as alfalfa, dogwood, ryegrass, sudangrass, Mexican corngrass, elephant grass, hemp and other forages; Corn straw, soybean straw, wheat straw, sorghum straw, rice straw, rice husk and other crop straw; Corn, wheat, soybean, soybean meal, sunflower meal and other grains; All kinds of premixes.

Therefore, the project has a stronger flexibility, and the customer’s raw materials are highly optional.

Can produce a variety of animal feed

An animal feed production line of the Saudi Arabian customer enables the production of both cattle and chicken feed pellets. Besides, more kinds of animal feed can be produced by changing the formula.

As a cattle feed pellet plant, it can also produce sheep, rabbits, horses, camels and other ruminant feed pellets.

As a chicken feed production line, it can also produce duck, goose, quail, pigeon, Turkey and other poultry animal feed pellets.

Main equipment of the animal feed production plant in Saudi Arabia

Grass Hammer mill

Feed crushing machine

Feed mixing machine

SZLH animal feed pelletizer

Feed pellet cooler

Feed pellet crumbler

Screening machine

Automatic packing machine

Reasons of the Saudi Arabian customer chose RICHI

The customer spent half a month in China for the animal feed production business plan and got to know a number of pellet machine equipment suppliers. Finally, the customer chose to cooperate with RICHI Machinery.

Solution Advantage

The customer spent half a month in China for the animal feed production business plan and got to know a number of pellet machine equipment suppliers. Finally, the customer chose to cooperate with RICHI Machinery.

Equipment advantage

RICHI Machinery has senior feed machinery industry experts, professional mechanical designer team, technical team and sales team, will tailor-made for each customer to create the most suitable production line solution and pellet equipment.

Price advantage

The Saudi Arabian customers visited RICHI’s factory, and they learned that RICHI has international advanced equipment production process and manufacturing equipment. In addition, they can also see our high-quality equipment materials and accessories.

Service advantage

We can provide customized and turnkey services to our customers. From the customer’s initial inquiry, solution customization, project construction, to the running of the pellet plant, we can always provide service and solve problems for customers.

More RICHI animal feed production lines and equipment

Global cases of RICHI animal feed production line

Animal feed processing plant

- Country: Kuwait

- Date: October 17, 2023

- Capacity: 1-2T/H

- Guide price: 38000 US Dollars

RICHI Animal feed pellet plant

- Country: Senegal

- Date: October 14, 2023

- Capacity: 5-7T/H

- Guide price: 303650 US Dollars

Animal feed production plant

- Country: Russia

- Date: September 26, 2023

- Capacity: 3-4T/H

- Guide price: 69350 US Dollars

Feed production line with Grass feed pellet machine

- Country: Moldova

- Date: July 14, 2023

- Capacity: 10T/H

- Guide price: 209240 US Dollars

Floating fish feed pellet production line

- Country: Lebanon

- Date: June 7, 2023

- Capacity: 1-2T/H

- Guide price:58500 US Dollars

Poultry Feed Pellet Line

- Country: Nigeria

- Date: April 24, 2023

- Capacity: 1-2T/H

- Guide price: 40470 US Dollars

animal feed plant

- Country: New Zealand

- Date: December, 16, 2022

- Capacity: 20t/h

- Guide price: 27700 US Dollars

Animal feed pellet production line

- Country: KZ(Kazakhstan)

- Date: December, 4, 2022

- Capacity: 5-7T/H

- Guide price: 92610 US Dollars

Livestock poultry feed pellet plant

- Country: Botswana

- Date: April, 28, 2022

- Capacity: 5-7T/H

- Guide price: 74020 US Dollars

Feed pellet production line

- Country: Iraq

- Date: March, 9, 2022

- Capacity: 20t/h

- Guide price: 506000 US Dollars

Cattle feed pellet plant

- Country: Katar

- Date: January 16, 2020

- Capacity: 3T/H

- Guide price: 33040 US Dollars

RICHI Animal feed Manufacturing plant

- Country: America

- Date: May, 1, 2019

- Capacity: 10T/H

- Guide price: 349600 US Dollars

Frequently Ask Question

Frequently Ask Question

Click Here to buy now.

How does grass content affect animal feed production line capacity?

Generally, the smaller the grass proportion, the higher the capacity of the animal feed production line. The specific capacity depends on the animal feed pellet machine model we use.

The following shows the capacity of RICHI’s 4 feed pellet models under different grass content conditions.

| Pellet Machine Model | 10%grass and 90% grain | 20%grass and 80% grain | 30%grass and 70% grain | 40%grass and 60% grain | 50%grass and 50% grain | 60%grass and 40% grain | 70%grass and 30% grain | 80%grass and 20% grain | 90%grass and 10% grain | ||||||||

| Capacity(T/H) | |||||||||||||||||

| SZLH 320 | 3.4 | 2.6 | 2.4 | 2 | 1.7 | 1.5 | 1.3 | 1.1 | 0.7 | ||||||||

| SZLH 350 | 4.2 | 3.5 | 3.0 | 2.4 | 2.1 | 1.8 | 1.6 | 1.4 | 1.0 | ||||||||

| SZLH 420 | 8 | 6 | 5.5 | 4.6 | 4.2 | 3.5 | 3 | 2.6 | 2.0 | ||||||||

| SZLH 520 | 12 | 9.5 | 8 | 6.5 | 5.7 | 5.2 | 4.2 | 3.6 | 3 | ||||||||

Any Question?

You can ask anything you want to know about Feedback