Animal Feed Pellet Plant

1-100t/h animal feed pellet plant at a factory price. And also quality pellet mill equipment, reasonable solution design, customizable animal feed production line.

Animal feed pellet plant Price

An animal feed pellet plant’s capital cost is about $30,000 to $3,000,000. The main reasons for the price difference are the differences in feed pellet capacity and types, different processes and different machine configurations. These are mainly to meet the customer’s individual needs for animal feed pellet production.

As a manufacturer of animal feed pellet equipment and turnkey service provider of pellet production line, RICHI Machinery can provide customers with a one-stop solution to establish 1-100T/H animal feed pellet plant.

- Capacity: 1-100T/H

- Model of Feed Pellet Machine: RICHI SZLH feed pellet machine

- Customizable: Yes

Application Of 1-100T/h animal feed pellet plant

Raw materials that can process

1 to 100 tons per hour of animal feed pellet plant can process raw materials including energy types such as corn, wheat, barley, proteins such as beans, rapeseed, soybean meal, fish meal, various feed additives, etc. These ingredients are usually mixed to make pellets according to demand. It can be seen that the produced feed pellets are also nutrient-rich and comprehensive, which is very beneficial to the growth of animals.

Final feed pellets

The feed pellet size made by RICHI SZLH series animal feed pellet makers is 2-12mm. The final feed pellet size after the crumbler is 0.8mm-2.0mm. So, small pellets are very friendly for young animals.

If you want powder feed, you can also directly pack the raw materials after crushing and mixing, without the need for pelletizing.

Animals can be fed

Animal feed pellets made by 1-100t/h animal feed pellet plant can be used to feed poultry such as chickens, ducks, geese; livestock animals such as pig, cattle, sheep; pets such as dogs, cats; aquatic products such as fish, shrimp. As an efficient and convenient feeding food, feed pellets are popular for the majority of farmers. Besides, reasonable feed pellet feeding can improve the growth rate and quality of animals, and reduce the breeding cost.

Main sections and equipment

Today we introduce a animal feed pellet production line with manual batching, because its price is relatively low.

1.Receiving and cleaning section

- Main equipment: Precleaner

- Other equipment: Pulse dust collector, Premanent magnetic drum, etc.

Using for raw material receiving and impurity removal.

2.Crushing section

- Main equipment: Hammer mill

The grain raw materials are crushed into powder form by RICHI SFSP series feed hammer mill.

3.Mixing section

- Main equipment: Mash feed mixing machine

Mixing the crushed grain raw materials, premix, addtive and grease evenly. High mixing uniformity, short mixing time.

4.Pelletizing section

- Main equipment: Feed pellet mill

The mixed animal mash feeds are made into 2-12mm feed pellets by feed pellet mill.

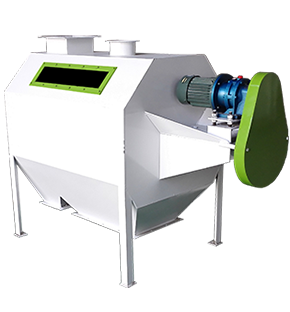

5.Cooling and crumbling section

- Main equipment: Cooler

- Other equipment: Crumbler

The cooled feed pellets enter the crumbler and can be made into smaller feed pellets..

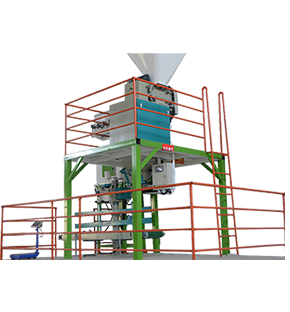

6.Packing section

- Main equipment: Packing machine

The finished feed pellets are screened and automatically weighed and packed.

More equipment: Bucket elevator, air lock, impeller feeder, stock bin, premix inlet hopper, cyclone, finished goods bin, sewer and conveyor, electric cabinet, grease adding, air compressor, steam supply system, electric hoist, etc.

The feed pellet plant can choose the necessary sections according to its own needs, as well as the necessary processes and equipment in each section. Because each animal feed pellet plant is equipped with different equipment, the steel frame demand for the factory is also different, so the price is also very different.

Feed pellet maker on animal feed pellet production line

Feed pellet mill is the main equipment of the whole animal feed pellet plant or feed pellet production line. Not only is the output controlled, but different feed pellet mills are also required for processing different animal feeds. As well as, RICHI SZLH series feed pellet mill can be divided into livestock and poultry animal feed pellet maker, ruminant animal feed pellet maker, and aquatic animal feed pellet maker.

01

Livestock and poultry feed pellet maker

Suitable for poultry feed pellet plants. With a single layer conditioner. The feed mash materials and water vapor are mixed in full contact in the conditioner, and then enter the granulation chamber for pelletizing. This is the most basic feed pellet mill. So, users should be concerned about the performance, stability and durability of the livestock or poultry feed pellet machine. Henan RICHI Machinery’s animal feed pellet makers have advanced technology and reliable quality assurance, and can provide users with long-term stable support and service.

RICHI

Suitable for cattle feed plants. Single layer conditioner and force feeder. After the feed mash material and water vapor are fully mixed in the mixer, they enter the granulation chamber for pelletizing under the action of the force feeder. In order to adapt to the special digestive mode of ruminants, ruminant feeds are added with grass such as alfalfa. The force feeder helps with the pelletizing of grass, and other light raw materials. Generally, the proportion of grass in the mash feeds is more than 30%, which will require force feeding.

RICHI

03

Aquatic animal feed pellet maker

Suitable for fish feed production lines. The double-layer conditioner is used for the sinking fish feed pellet, to improve maturity and gelatinization of the feed. This is helpful for fish diet and digestion and absorption.

And the three-layer conditioner is needed for the shrimp pellet feed to better control the temperature and humidity of the feed. The three-layer conditioner helps produce high-quality, high-nutrition shrimp pellet feed to meet the growth needs of shrimp.

RICHI

Benefits of crumbler in animal feed pellet plant

The crumbler is used to crush the cooled feed pellets to obtain a smaller size (about 0.8mm -2.0mm) of the finished feed pellets. If the pellets coming down from the cooler no longer need to be crushed, they can flow out directly from the bypass.

- The crushing rate of the crumbler is 60%-70%. A screener at the back will screen the feed pellets, larger pellets can be re-crushed, and the smaller or powder feed can be recycled and re-granulated.

- Pellet crumbler can reduce feed waste, reduce production costs, and bring economic benefits to animal feed pellet plants.

- The use of pellet crumbler helps to improve the utilization rate of feed, and animals better digest and absorb the nutrients in smaller feed pellets.

- The smaller the feed pellets produced by the feed pellet mill, the lower the capacity. Therefore, when small feed pellets are needed, choosing a crumbler can increase the capacity of the animal feed pellet plant.

RICHI MACHINERY

1-100T/h animal feed pellet plant builder

Henan RICHI Machinery CO., LTD. was founded in 1995, it develops and advances together with modern agriculture and animal husbandry. There is a professional technical team to continuously improve the production process and constantly upgrade the equipment. We not only have many years of industry experience, but also have machines that have been debugged many times and successful cases.

From site planning, equipment selection, process flow to installation and operation, each link is strictly controlled by professionals. Our goal is to provide our customers with a high quality, efficient and profitable animal feed pellet plant.

RICHI can build animal feed pellet plants with the capacity of 1-100t/h, and can also build grass pellet plants, wood pellet plants, biomass pellet plants, organic fertilizer pellet mill, etc.

Contact us to build your own 1-100t/h animal feed pellet plant within your budget.

Frequently Ask Question

Frequently Ask Question

FAQs of building a 1-100t/h animal feed pellet plant

What does it take to set up an animal feed pellet plant?

For the investors with 1-100t/h feed pellet production, some are to meet their own needs, and some are for sale on the basis of their own needs.

First of all, you need to determine your own feed pellet product and understand the feed demand. Ensure that the produced feed pellets are not trapped in the warehouse and ensure the profitability of the animal feed pellet plant.

Secondly, you need to make a plant construction budget and site planning, and be fully prepared to choose your own animal feed pellet production line.

Finally, you need to choose advanced and mature production technology, and the equipment of feed pellet production line has stable performance, easy operation and easy maintenance. In the future production process, there are good production efficiency, low failure rate, and worker-friendly production environment.

How much labor does a animal feed pellet plant need?

We take a complete 5-7 tons per hour animal feed pellet production line as an example, the inlet hoppers need 1 or 2 workers, the premix inlet hopper needs 1 worker, the electric cabinet of the animal feed pellet maker needs 1 worker, the packaging machine needs 1 or 2 workers, and also you can add a production manager. A total of 5-7 labors.

If you don’t want to have the workers, you can choose a fully automated pellet feed production line.

How to choose a solution for 5-7 t/h feed pellet production?

The selection is based on the factors such as the type and size of feed pellets, available funds, the size and height of the plant. Contact RICHI Machinery for your needs, RICHI Machinery is a company specializing in customized feed pellet production solutions and also a pellet mill manufacturer, has built 5-7 tons per hour animal feed pellet plants for many customers.

Any Question?

You can ask anything you want to know about Feedback

How to dust the workshop?

Centralized dust removal includes pulse dust collector, air lock and draught fan. Becase of there is a large amount of dust in the grain raw materials and the production process of feed pellets. So, it is very important to protect the working environment of workers, as this directly affects their health.

What is the function of the boiler in the animal feed pellet plant?

The function of the boiler in the animal feed pellet plant is to produce water steam, and then the steam passes into the conditioner of the animal feed pellet maker, and contacts with the powder materials for mixing and modulating.

The temperature of the steam is higher, and the temperature of the powder materials can raise when they are in contact with the steam. This makes the feed pellets easier to form during the pellet chamber extrusion process. High temperature helps to kill bacteria, reduce the bacteria of feed pellets, so that animals are not easy to get sick after eating, and easy to digest.

After steam cooling, it has a wetting effect on the surface of the powder materials, which helps to improve the output of the feed pellet mill and make the pellets more full and shiny. However, it is also necessary to control the appropriate steam temperature and modulation time to avoid negative effects on animal feed pellets.

Is the stock bin necessary?

Stock bins are not necessary. But if you want continuous production, you still need stock bins. The function of the stock bins is to connect the material storage issues from batch to batch. If there is no stock bin, at the same stage, the hammer mill, the mixer and the animal feed pellet maker can only have one machine doing useful work.

Who can help you build a animal feed pellet plant without worry?

RICHI machinery is beyond doubt. Because RICHI machinery is the feed pellet mill manufacturer. Quality clearance, rich experience, and reliable after-sales.