1-2T/H Animal Feed Pellet Production Line

1-2T/H animal feed pellet production line is very popular in feed industry because of its low cost and small footprint.

RICHI MACHINERY

RICHI 1-2T/H Animal Feed Pellet Production Line Details

Our 1-2T/H animal feed pellet production lines have a variety of solutions. We can supply a customization solution according to customer needs. For example, customized conveyor, limited plant height, limited plant area, packing method, cooling model for finished feed pellet, agitator tank or mixer, containing grass raw materials, PLC batching, etc.

- Considering that some customers have limited budgets, we offer multiple 1-2t/h animal feed pellet production lines at various factory prices from $10,000 to $60,000.

- Taking into account the customer’s plant, RICHI Machinery also provides different sizes for the 1-2 tons per hour animal feed production lines, which is mainly determined by feed pellet equipment itself and installation methods.

- Application: Sutiable for production of feed pellets for poultry, livestock, aquatic animals, etc.

- Raw Materials: Corn, wheat, soybean, soybean meal, rapeseed meal, forage grass, alfalfa, premix, additives, etc.

- Pellet Size: 1.5-12mm

Are you worried about not knowing how to choose a proper animal feed pellet maker? Are you struggling to find reliable animal feed pellet production line manufacturer or supplier? HENAN RICHI MACHINERY CO., LTD. is a feed pellet machine manufacturer and pellet machinery leading enterprises in China.

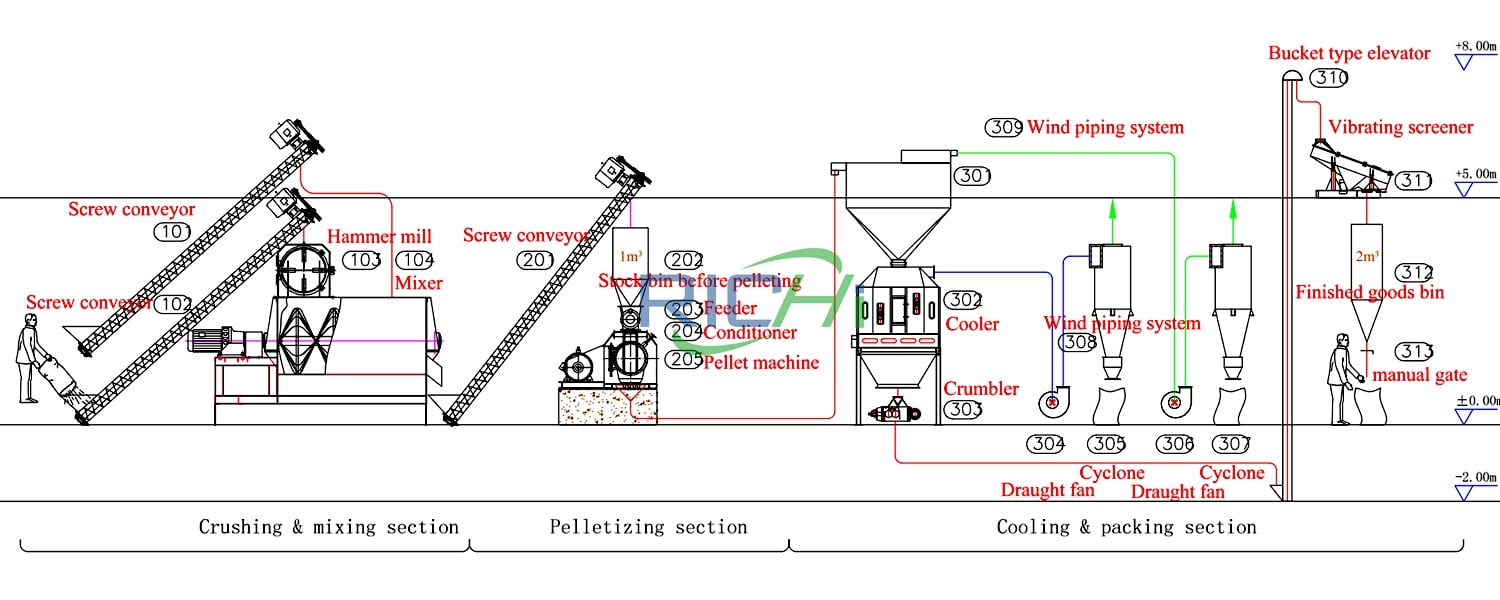

1-2T/H Animal Feed Pellet Line Flow Chart

This is a manual animal feed pellet production line with a capacity of 1-2t/h. Including crushing, mixing, pelletizing, cooling and packing sections.

- The raw materials include soybeans, corn, wheat, barley, grain, rapeseed meal, soybean meal, alfalfa, grass, etc.

- The 1-2T/H animal feed pellet production line from RICHI Machinery can process chicken feed pellet, duck feed pellet, pig feed pellet, cow feed pellet, cattle feed pellet, camel feed pellet, alfalfa pellet, fish feed pellet, floating fish feed, shrimp feed pellet, pigeon feed pellet and so on. The feed pellet production line can also become a combined line of two feeds, which can meet the production needs of customers for two different feed pellets, such as chicken feed pellet and fish feed pellet. And we have had similar successful cases before.

- We has rich experience in 1-2t/h feed pellet production line, and also can easily solve various technical problems for customers. We can grasp the details that affect the quality and yield of feed pellets.

Advantages of the 1-2T/H animal feed line

Follow the flow chart above, from left to right. RICHI will be considered for the customer every step in place in the design of the program.

1.There are two screw conveyors. One transports the pellet raw materials to hammer mill, and one transports the powder materials directly to the mixer.

2.There is a stock bin in the pelletizing section, which is just above the feeder of the animal feed pellet press. The advantages of the stock bin are that the animal feed pellet press is not easy to block the materials and the front screw conveyor does not need to limit the feed speed.

3.There is a crumbler under the cooler. The feed pellet size made by animal feed pellet maker is 2-8mm. And the feed pellet size made by crumbler is 0.8-1.8mm. The 1-2T/H animal feed pellet production line can produce smaller feed pellets, which are better absorbed by animals. If the pellet size of the feed produced by animal feed pellet maker becomes smaller, the yield will be lower. Therefore, the addition of crumbler can improve the production capacity of animal feed pellet production line.

4.The cooling section has two cyclones for better dust removal. The bucket type elevator in the cooling and packaging section needs to be buried 2 meters underground, with the highest height reaching 8 meters. Noting that the height of the factory building is sufficient.

5.The packaging system uses manual packaging to save costs. If you want to save labor, you can use an automatic packaging system.

Main Equipment

If you want to know more about the parameters, equipment, price of these single machines or feed pellet machine price, you can find out on our website, or send an inquiry to us.

SZLH250 animal feed pellet maker

Feed Pellet cooler

Pellet crumbler

More Animal Feed Production Line Solutions

If you have sufficient funds, the height and space of the plant can meet the requirements, or you want to build a new feed pellet production line on an empty lot, please contact us. We can custom-make your own animal feed pellet production lines. In addition, a relatively automated animal feed pellet production line allows you to use less labor.

Project cases of 1-2T/H animal feed production line

RICHI Machinery is a manufacturer of pellet machinery. So, we allows customers to customize 1-2T/H animal feed pellet production lines directly from the source factory.

We have our own operations team and sales team, so that customers do not need to take resources from agents. Many customers will still choose RICHI machinery after visiting more than 10 pellet machine factories in China. Mainly because our mechanical equipment and prices are very reasonable, and also we can give customers the greatest help and cost-effective.

With a responsible attitude towards each customer, we will return visits and follow up with customers. We will solve the problems in feed pellet production in time. In this process, we have also maintained a good relationship with our customers.

Look at two typical cases. The following is an Australian customer’s 1-2t/h chicken feed pellet production line, and an Uzbekistan customer’s fish feed and animal feed production combined line.

1-2T/H chicken feed production line for Australian customer

The chicken feed pellets produced by this customer are for feeding chicken directly and not for sale. So, 1-2 tons per hour chicken feed pellet production line is enough. Besides, the automatic packaging section is also unnecessary. And we have omitted it in the scheme, which reduces the customer’s capital investment. Australia has quality requirements for chicken feed, which tests the quality of pellet press and the rationality of pelletizing process.

The advantage of the 1-2 tons per hour chicken feed pellet production line is also small footprint. Main equipment have SFSP animal feed crushing machine, SLHY ribbon feed mixer, SZLH250 animal feed pellet maker, SKLN Series Counterflow Cooler, vibrating screen classifier, pulse dust collector, etc.

The customer is very satisfied with the 1-2 t/h chicken feed pellet production line, think it is very reasonable, and the output is very sufficient. Besides, praise the dust-proof design of the pulse dust collector. The customer said that the production line is suitable for his own plant and also is profitable.

Feed pellet production combined line for multiple feeds

Let’s introduce a feed pellet production combined line, which can be used to produce 1 t/h floating fish feed or 1-2t/h animal feed pellets. The customer comes from Gizak,Uzbekistan. The raw materials used for processing include corn, soybean meal, oil and premix.

In this feed pellet production combined line, the pelletizing section is a key point. The floating fish feed extruder machine and SZLH-250 feed pellet making machine are used. The feed pellet production combined line is more complex in design and project landing process than the production line with a single animal feed pellet maker.

RICHI Machinery has a professional team of industrial designers to optimize the program and cooperate with the R & D team to solve technical problems. After the project starts, there will be specialized technical workers and installation masters to go to the site to ensure the smooth completion of the production line. RICHI Machinery also trains the operators responsible for production, to ensure the normal operation of the feed pellet production combined line.

RICHI MACHINERY

Pellet Machine Industry Leader

As China’s leading pellet machine and feed pellet production line enterprises, RICHI Machinery is worthy of customer trust and long-term cooperation. RICHI Machinery has been committed to the research and development, manufacturing, installation and commissioning of feed pellet machines, feed pellet production line and feed pellet plant for years.

Our company has always insisted on customizing feed pellet production line, biomass pellet production line, wood pellet production line, animal feed pellet maker, and other related pellet making machinery.

RICHI Machinery has successful cases of 1-2T/H animal feed pellet production lines in many countries and regions, and has won unanimous praise from customers. We have always believed that there is no perfect animal feed pellet production line solution, only a design that suits the needs of our customers.

RICHI Machinery is feed pellet production line manufacturer and supplier. RICHI Machinery’s feed pellet production process is mature in the industry, and high-quality materials are selected for feed pellet production equipment. We need to know that different solutions meet different customer needs. There is no perfect animal feed production line, only suitable for your own program. Contact us for your own 1-2T/H animal feed pellet production line.

Frequently Ask Question

Frequently Ask Question

How to Choose Your Own 1-2T/H Animal Feed Pellet Machine?

Animal feed pellet machine is the main equipment of the 1-2 T/H animal feed pellet production line, we need to emphasize it. Broiler or chicken feed pellet machine and pellet making machine for poultry feed are single-layers conditioner, fish feed pellet machine is 2-layers conditioner, shrimp feed pellet machine is 3-layers conditioner. Cattle feed pellet machine, hay pellet machine and other ruminant feed pellet machines have forced feeder.

How to Choose Your Own 1-2T/H Animal Feed Pellet Production Line?

- What kind of feed do you want to produce? Poultry feed pellet, ruminant feed pellet, aquatic animal feed pellet, or powdered feed? According to the different final animal feed types, we have to choose different feed pellet machines or production lines to adapt to the characteristics of the feed.

- How much money do you want to invest? RICHI Machinery has animal feed pellet machine for sale. There are also different feed pellet production lines for customers to choose. We will also recommend the animal feed pellet production line with the corresponding price according to the customer’s budget, while meeting the feed production needs.

- What is the size of the original plant or the area of the new plant you want to build? Different processes of the 1-2T/H animal feed pellet production line have different heights and floor area, this is what we have to consider.

- How many workers do you want to use in daily production? We can control the manpower requirements from the automation of the animal feed pellet production line.

- In addition, if there are local conditions such as the difference in soil quality, the particularity of electric power, etc., RICHI Machinery will help solve these technical problems.

- Is the quality of the feed pellets produced acceptable? Pellet feed is used to feed animals, and its quality directly affects the health and growth of animals. The process of the 1-2 t/h feed pellet production line and the material of the equipment have an impact on the quality of the final feed pellets. For example, ring die of feed pellet machine, press roller, conditioner and other parts, whether the use of stainless steel.

- The durability of the 1-2t/h animal feed pellet production line also needs to be considered, because of the damage of the equipment will directly affect the production and income. For some worn parts, RICHI Machinery also uses good materials to avoid the frequency of replacement.

Any Question?

You can ask anything you want to know about Feedback